Ammo & Reloading [The Definitive Resource]

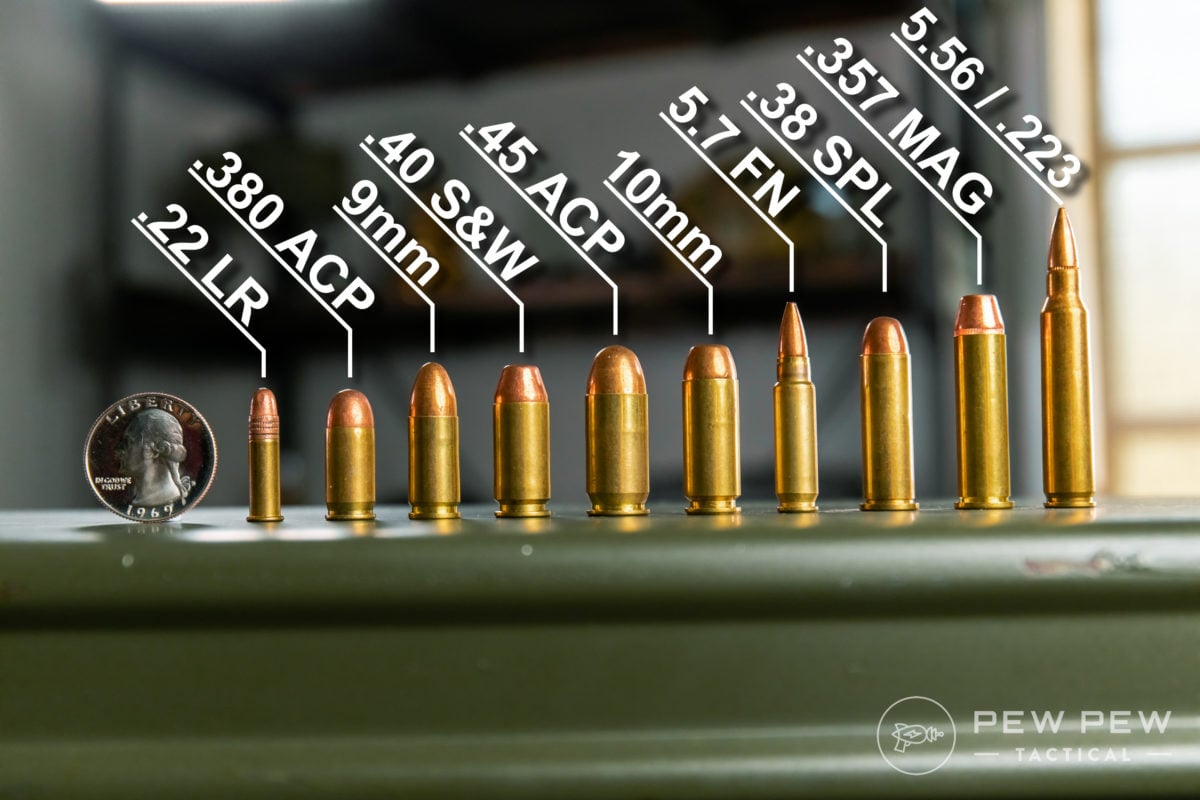

Not sure of the best ammo for you gun? Learn about the different types of ammo that’s best for different purposes such as range, hunting, & home defense. And then find our favorite picks for each type of firearm from pistol to rifle and shotgun.

Chapter 1

Ammo Guides & Where to Buy Online

Start here to learn about ammo basics, where to find the best ammo deals online, and the current in-stock choices.

Chapter 2

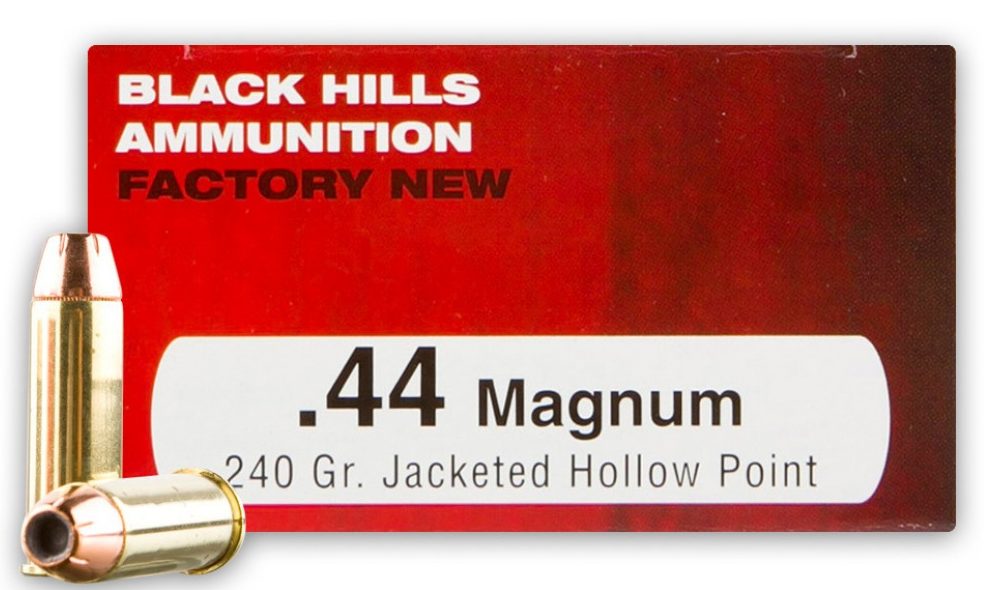

Pistol Ammo Recommendations

Find out the best brands for common pistol & revolver plinking ammo to the best hollow point defensive ammo.

Chapter 3

Rifle Ammo Recommendations

From the AR-15 to the AK-47 and everything in between…we’ve got all our favorite rifle ammo recommendations right here.

-

General Ammo Guides

-

AR-15 Specific

-

Longer Range Calibers

-

Rimfire Cartridges

Chapter 4

Shotgun Ammo Recommendations

Looking to feed your shotgun? Here’s everything we’ve got from birdshot to buckshot and even slugs.

Chapter 5

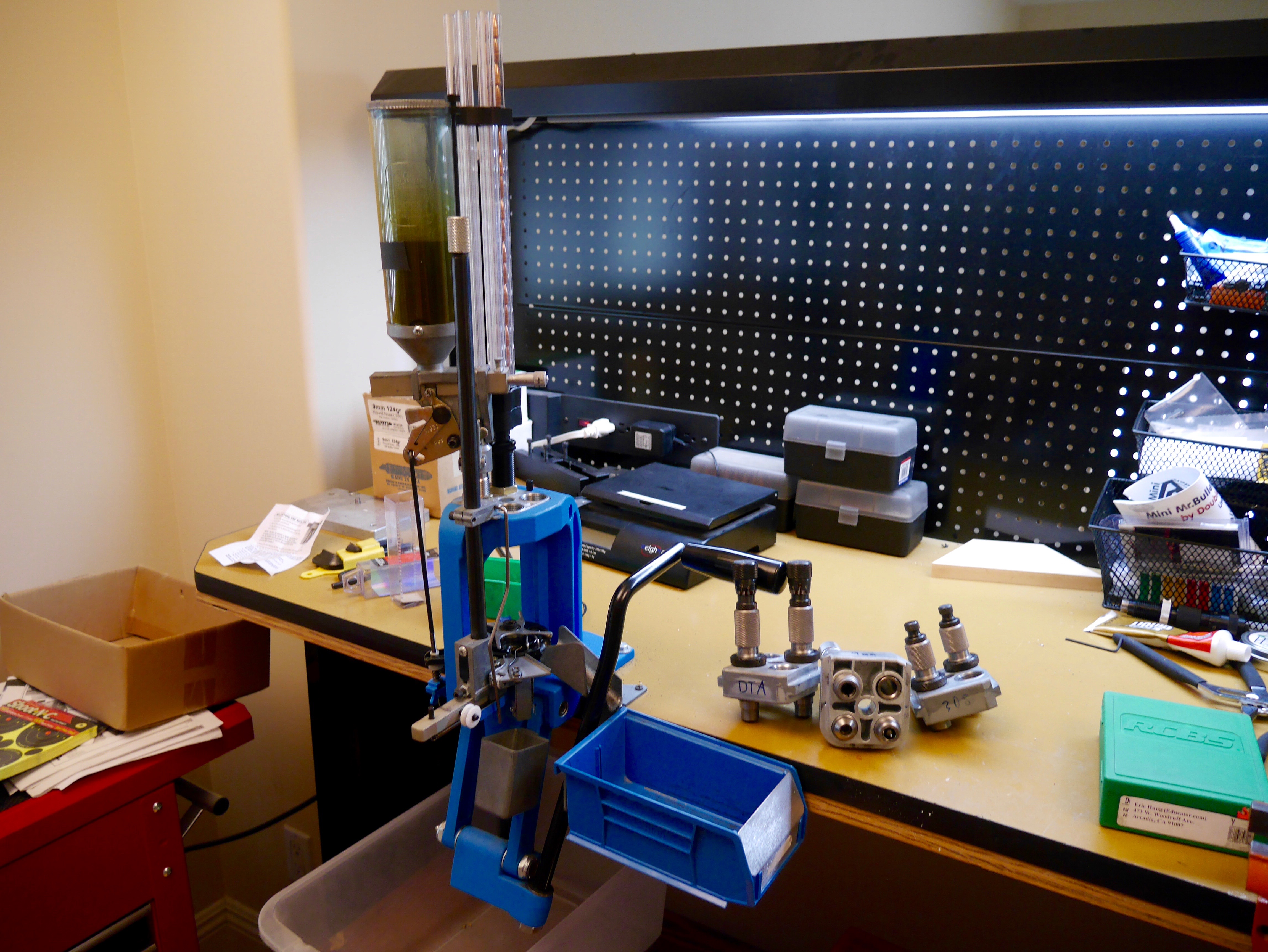

Reloading

Ready to make your own ammo for savings and increased accuracy? These guides will help you out from beginning to end with reloading basics to choosing the right equipment and then building up your load.

-

General Guides

-

Gear & Components

-

Procedures