Biden unveiled a new rule that would make it illegal as of August 24, 2022 to manufacture a kit without a serial and for resellers to sell without conducting a background check. It’s currently being challenged so we’ll see what happens!

Update: As of November 2022, 80% Arms is exempt from the current ban so you’re able to buy both jigs and receivers together.

Looking to complete your own AR 80% lower receiver?

Today, we’re going to go over the best 80% AR-15, AR-10, and AR-9 lower receivers out there. And…we’ve done our fair share of 80% through the years.

Plus, the best jigs to help you get to the 100% mark.

And most recently…we’ve even added our favorite Glock 80% frame projects.

Here’s our favorite picks…but given the current situation things are selling out fast.

THE QUICK LIST

-

AR-15 80% Aluminum Pick

-

AR-10 .308 80% Pick

-

9mm AR 80% Pick

-

Editor’s Pick 80% Jig

-

The OG Glock-clone Kit

-

Also Good Pistol Build

And for Polymer80 Glock-style builds, check these quick links (selling fast):

- PF940V2 for Glock 17 Gen 3

- PF9SS Single Stack for Glock 43

- PF940SC for Glock 26/27 Gen 3

- PF320 for a Sig P320 Build

- PFS9 Full Size AFT Builder Kit

Table of Contents

Loading…

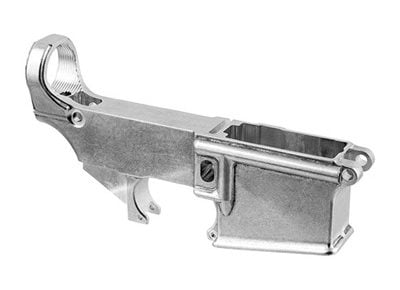

Brief Overview of 80% Lowers

First, you should really check out our other article on what exactly is an 80% lower.

TLDR; an 80% lower receiver is an unfinished lower that is nominally sold as a “paperweight” or other novelty and not a firearm.

If you’re buying a finished AR lower, you’re technically buying a firearm in the eyes of the ATF.

Meanwhile, an 80% lower is technically not a firearm until you finish machining it, so you can get them delivered straight to your house without paying FFL fees.

As long as you’re manufacturing the firearm for personal use, and are otherwise allowed to own said firearm in your state, you’re good to go.

Yes…it’s a “ghost gun” in that most places don’t require serializing/registration, but that’s a loaded term so we won’t be using it for the rest of the article.

Best AR-15 80% Lower Receivers

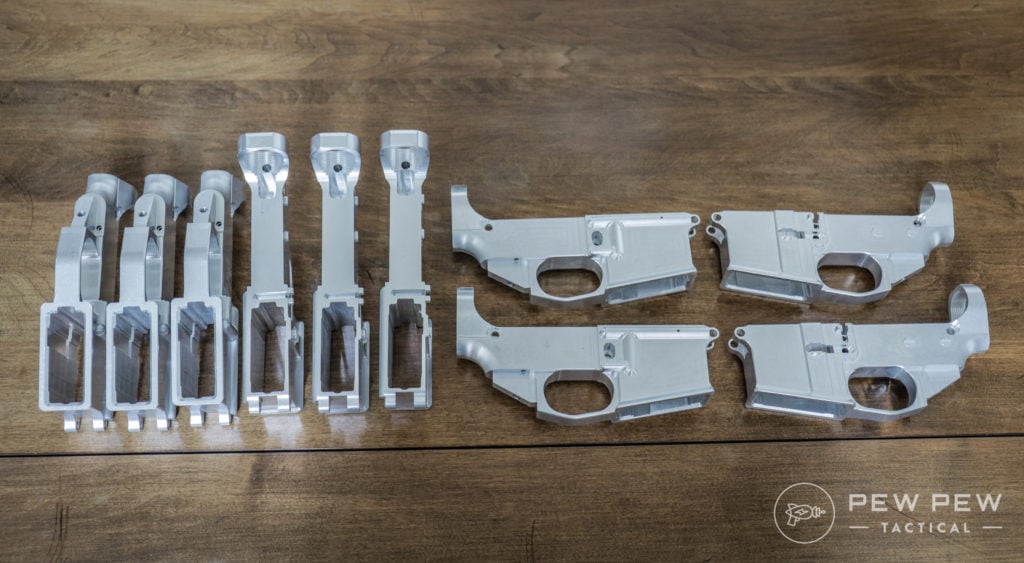

Let’s start with the most popular of 80% lowers…the AR-15.

1. 80% Arms

Their AR-15 80% lower is 6061 billet but is cleanly machine and is anodized very well in the two our team has completed.

Billet gives you the ability to have some slight differences from more mil-spec lowers…such as more aggresive lines which I like.

The 6061 aluminum also made it possible to do deeper milling cuts each time which saves time (more on this in the jigs section).

Plus they work perfectly with 80% Arms’ jig.

And the finished product has worked in all our tested uppers.

Check out the full review of the entire process here. We’ve gone through both Gen 2 and Gen 3 versions.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Or check out their other 80% versions like raw billet and even flat dark earth versions.

Want an easy kit to finish your lower build? Check out PSA’s MOE Lower Build Kit.

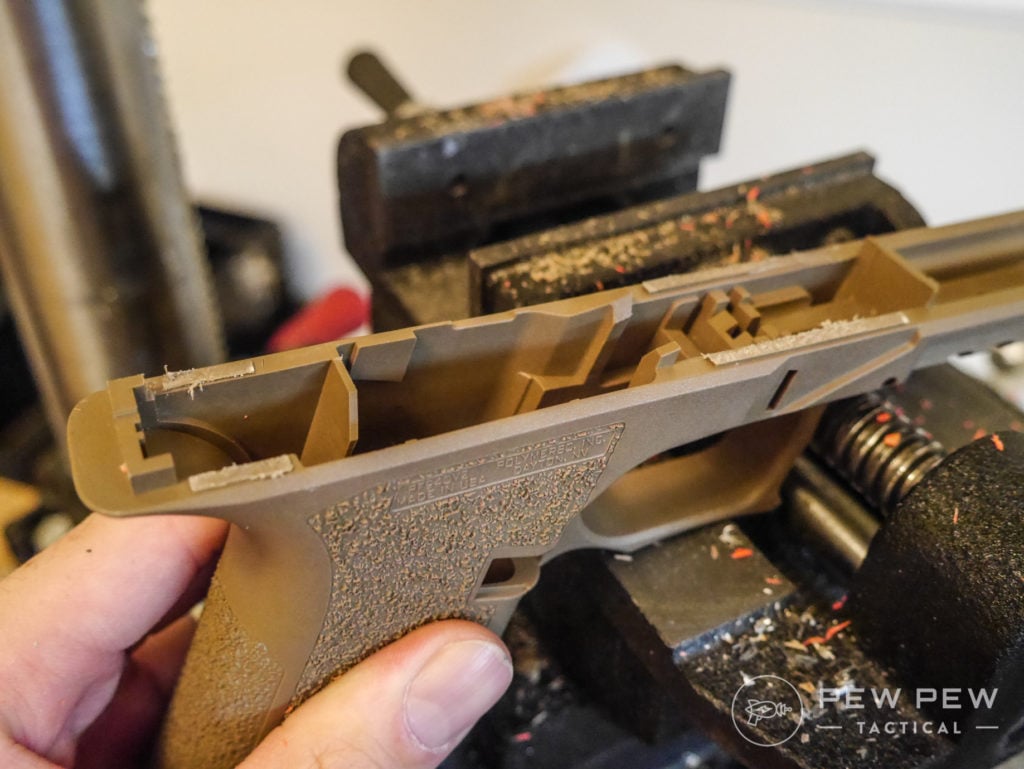

4. Polymer80

Polymer80 is the other contender for my first polymer lower, especially if I decide to go the 80% route. These guys and gals specialize in polymer 80% lowers…hence the name.

Of course…we’ve done tons of their Glock 17 and 19 80% builds.

They also have a freakin’ ton of cool colors available which is perfect if you like to personalize your builds a bit more.

For me, I like building AR’s not just to shoot, but also for the mechanical challenge that comes with this type of thing.

Its really fun to take a box of parts and turn it into a working rifle that you can hunt, compete, and even defend yourself with if need be.

The cool thing about Polymer80 lowers, besides the awesome colors, is the jig sets you can get with them.

For $80, you can get the lower, the bits you need, and the jig to guide you…basically, everything but you need except for the drill.

Hard to find as well nowadays.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Best AR-10 and AR-9 80% Lower Receivers

1. 80% Arms

There’s not as many AR-10 and AR-9 80% lowers out there so I gotta give it to 80% Arms since we tried them and they work well.

Check out the size difference in the AR-10 80% Lower.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

And I’m glad the mag latch is already installed in the AR-9 Lower. YES…it takes Glock mags.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Now…onto the jigs!

Best AR 80% Jigs

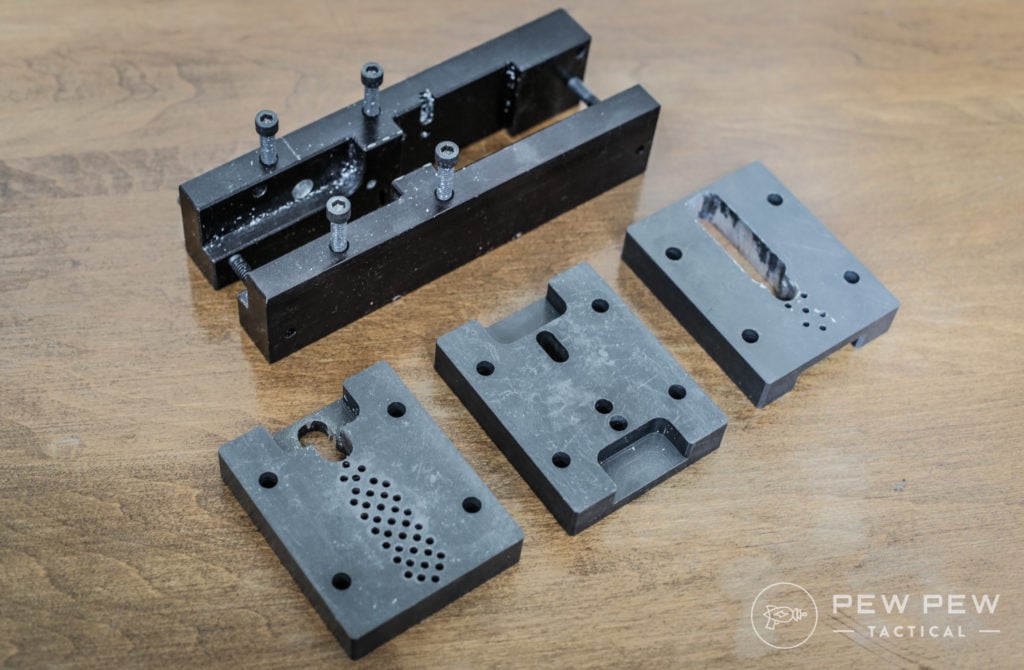

We’ve built a couple 80% lowers through the years…starting years with a jig where we had to send a money order to some guy. Or silver dollars…he took those too.

And for the longest time it was the same design…drill a bunch of little holes with your drill press first.

Then attempt to “mill” or cut off material in a horizontal manner with a drill press…something that was never meant to do that.

Result…lowers that still worked but took forever (~3-4 hours) and looked gross in the fire control pocket.

Enter the next generation of 80% jigs…where you only need a normal drill and a router.

Note: an 80% lower requires some pretty advanced machining, so the quality, fit, and finish of the final product is going to depend entirely on you.

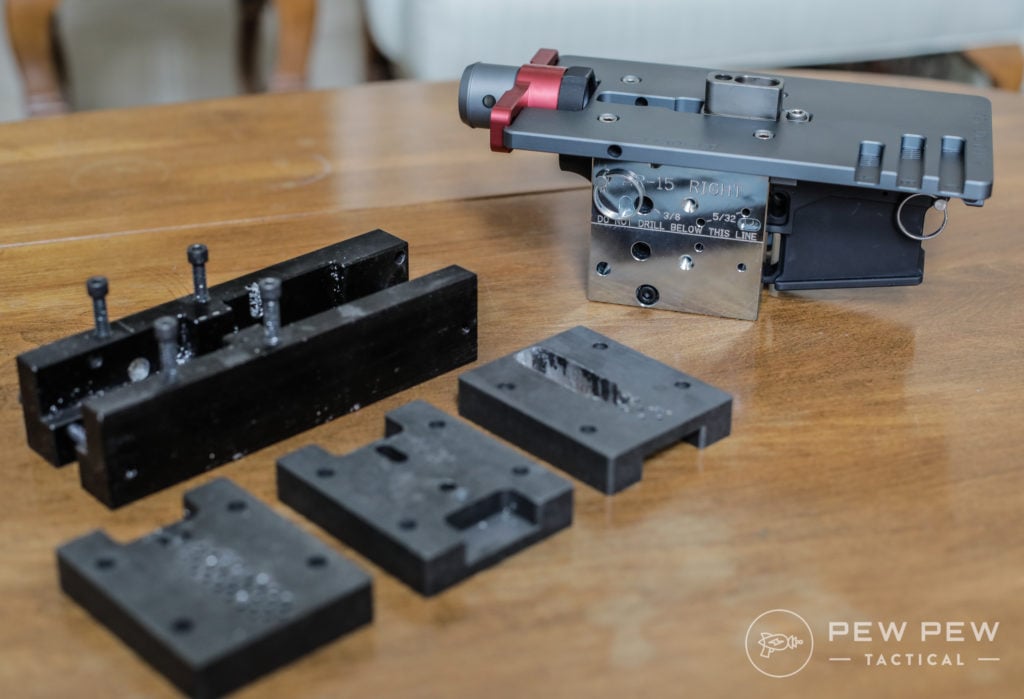

1. 80% Arms Easy Jig 3

Hands down the best 80% jig we’ve used is the Easy Jig 3.

We’ve also completed our Full Review of the Easy Jig with a corresponding video as well:

We got the multicaliber version which can easily make the AR-15, AR-45 and AR-9 platforms.

And that’s the router that basically spins the end mill bit…for our Gen 2 project we used a Ridgid R2401 Router ($90) that didn’t need any extra parts to work with the Easy Jig 2. For the Gen 3 build, we grabbed a router from 80% Arms.

We recommended getting the drill bits kit since it does need a special end mill. Or if you want to save a little money…get the end mill and the other things at Home Depot.

MUCH easier than the older jig designs and only took me about 1.5 hours.

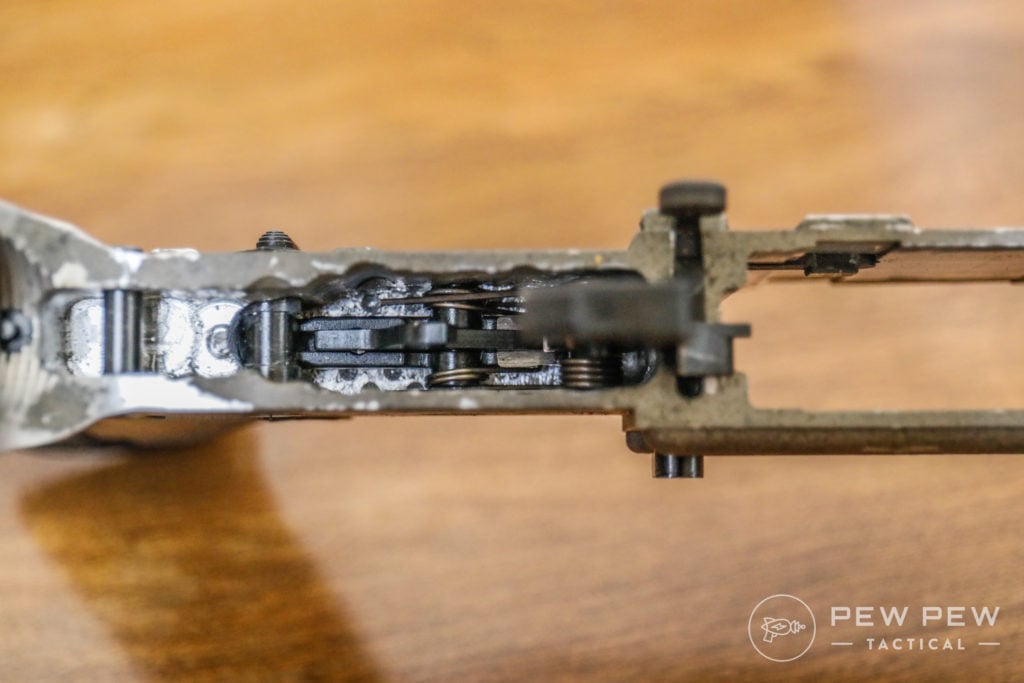

Here’s the final product…

It’s definitely on the pricier side at around $250…but you’re looking to save up to 2.5 hours per lower. I’d highly recommend just building more (lol) or splitting the cost with friends.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

What’s your take on the Easy Jig 3?

2. 5D Tactical Universal 80% Jig

Another contender in the router-based universal jig world is the 5D Tactical Universal Jig ($259).

Like the Easy Jig 3, it can do AR-15, AR-9, and AR-10 80% lower receivers.

So far it looks like it has great reviews (and tons of fans in the comments) but is priced a little higher at $289.

We’re looking forward to testing this bad boy out in the future too!

Best Glock 80% Frames

1. Polymer80

I alluded to Polymer 80’s Glock frames above but now we’ll dive a little deeper. There’s also a ton of options based on what you want.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

There’s also tons of options for size of handgun (things are selling fast):

- PF940V2 for Glock 17 Gen 3

- PF9SS Single Stack for Glock 43

- PF940SC for Glock 26/27 Gen 3

- PF320 for a Sig P320 Build

- PFS9 Full Size AFT Builder Kit

Fancy a super custom Gucci Glock with all its parts handpicked? Or simply want the satisfaction of building one yourself without the hassle of going to the gun store?

P80’s kits now range from the Glock 19, Glock 17…

And now even the single stack G43 series.

They are MUCH easier to complete than AR-15 lowers since you’re dealing with polymer material instead of aluminum. And there’s a lot less to remove.

You still need to be careful especially with the hardest part which is milling out the barrel block.

But I go through everything you need in my Polymer80 Glock Build Guide.

- kit overviews

- additional tools needed

- step by step instruction

- tips & tricks

- full parts list

2. 80% Arms

A relative newcomer to the Glock world is 80% Arms (which you should be tired of hearing by now) with their GST-9.

It’s similar in process to the Polymer80 but there’s some grip enhancements that let you switch between sizes.

Fancy a subcompact grip…boom! Want it a little larger to mimic a G19…boom!

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

We go through the entire process and build list…complete with video in [Review] 80% Arms GST-9 Build.

What Makes a Good 80% Lower?

There are a few things to consider when choosing your first AR-15 80% lower…

Name Brand

First, tempting as it may be, don’t buy from Uncle Leroy’s Backwoods Firearms.

Small manufacturers are extremely hit or miss, and often lack the precision of a larger, well-known manufacturer.

In firearms, as with most things, the “cover your ass” rule is firmly in place.

During one of the previous panic buy periods…we bought a no-name 80% that had multiple alignment problems and required re-drilling of pivot pin holes.

Materials

Polymer lowers are easier to machine, but are more prone to scratching and gouging as well as full-on breakage if you aren’t careful.

Make sure they are reinforced around the buffer tube area as well since that’s where most can fail.

Aluminum comes in two flavors, forged and billet.

Basically, the only thing you need to know is that forged aluminum is generally considered to be stronger, but almost no-one will get near the stress levels for it to come into play.

There’s also the issue of 6061 vs 7075 aluminum…6061 is softer and will be easier to machine.

7075 is the standard for “real” lower receivers but the difference in strength is so little that I doubt someone could break a 6061.

Plus, 6061 is actually more corrosion resistant.

Coating

One final consideration is the choice between anodized and non-anodized 80% lowers, assuming you’re working with an aluminum lower.

Personally, I would go with a non-anodized lower because you’re going to be milling out large portions of it and exposing non-anodized metal anyway.

Usually, that means you’re just going to have the thing re-anodized or paint anyway so I’d just go with the cheaper option of the raw aluminum.

Of course, you don’t have to worry about that with polymer as you’re just exposing more of the same polymer as you’re doing your machining.

Parting Shots

There you have it, folks. These are our favorite 80% lower manufacturers AND jigs.

Check our Best AR-15 Lower Parts Kits to finalize your lower and also our AR-15 Ultimate Resources if you need any help assembling or choosing parts.

There’s a good amount of choices for 80% lower receivers…from 6061 to 7075.

Need to choose other parts to complete your AR-15? Check our Best AR-15 Lower Parts Kits and also our AR-15 Ultimate Resources.

98 Leave a Reply

I've done four builds to date. Two .223 Wylde's and two .300 AAC's. For all of them I used Anderson 80% Lower receivers. The Jig I use, is a copy a machinist buddy made of his jig, so I'm not sure if he bought or milled his own jig (I suspect the latter).

The ATF's new rule has more to do with companies like 80% Arms selling complete kits, Jig, bits and Lower Receiver in one package or as the Rule reads "Everything at hand to readily build aFirearm. " As it was explained to me, you can still buy a jig, you can still buy bits and you can still buy a Lower, but you cannot purchase them all at one time. You have to spread the purchases out, or buy each from a different manufacturer

I've not purchased anything from 80% Arms, so I have no comment on their quality or service.

Stay away from 80 % arms! They are a bunch of thieves. They will take your money and you will never receive anything. Nor will they respond.

5D Tactical is the same company different name, I ordered a jig with 5 80% lowers kit and I got the lowers and the router and bits/ side mill but no jig. the rest are paper weights without the jig

It would be nice if this article (or a separate one) talked about uppers that are compatible with the 80% lowers/AR-9 lowers. I just spoke with Aero and they pretty much said, "Nope."

"Meanwhile, an 80% lower is technically not a firearm until you finish machining it, so you can get them delivered straight to your house without paying FFL fees. "

In a few days to a week that will not longer be true. The ATF will be publishing new rules in the federal register which makes these firearms period.

No

Why am I getting email for this reply? Not to you specifically Bob, but asking PEW PEW.

The 'John' to which you replied is not me. I also use the name John here but I did not make these posts yet i'm receiving email about a reply plus I don't check the box on my posts to get notified of follow-up comments by email. I think the pewpew system is screwed up

This guide conspicuously leaves out the actual company called "*80% Lowers" and they tend to have better receivers, parts kits and prices. In fact 80 Arms is a pretty sh*t company, but everything in here is almost exclusively referred to them. Pretty poor / paid off writing, imho.

My experience is totally different. 80% arms has great customer service. I lost one of the pins and they say they don't sell them, but they would ship me one at no cost. I received two. My 80% GST jig worked perfectly, my Plymer80 jig missed on the holes for the rear rail module/trigger housing. I also don't like the way they do the slide release spring. Note that this is a PF45. I have experience with only 1 GST-9 and one PF45 so my experience really isn't statistically significant. My 80% arms AR-15 and AR-308 turned out real nice too.

Looks like a bit of fun. But it's not worth the costs to me at this time. 100 and I get to spend half a day milling metal vs. 100 and a trip to the very close LGS (which is also a bit of fun)? Money being no object, I'd try it out. But it is THE object! Should prices come down, or I stumble across an unloved 80 jig, I'll definitely try it.

Having experience with both the 80% lowers & jig and the 5D Tactical lowers & jig I have to wonder if they are not manufactured by the same entity. Both turn out a very good, mil-spec product and the jigs are identical with the exception that one is anodized blue and the other is red.

I bought the jig and router at 80% arms and the router came with a 5d tactical sticker on it. Very god kit to complete a lower , they both look identical but the color.

Just bought 3 80% build kits at the tri County show here in PA. No legislation in sight here, and tom wolf talks about it all the time. Walked out with a glock 19, ar 15 556, and a ar 15 300 black out. All for around $1500. So I think we are in the clear. Lol

This article is in serious need of an update. Things have changed dramatically in four years:

New legislation, Ghost Gunner 3 CNC...

I feel like it was a bit cowardly to close the latest 80% lower commentt section.

Apparently the 2nd amendment “advocates” don’t appreciate the 1st.

The government didn't restrict your speech, so the first amendment doesn't remotely apply. Our team is small and we only have so many hours in the day. We can spend those hours working to produce outstanding content for our readers or we can spend those hours moderating comments on an article that was almost guaranteed to attract a huge number of spam, senseless argument, and internet keyboard warriors. We chose to deliver the information and then keep working.

Serious price gouging going on. I’m all about capitalism but doubling prices is bs.

I can't see it anywhere but does anyone know if 80% offers a military discount?

Interesting that you post this article as we are on the brink of an Executive Order(s) to ban these types of firearms. Being a machinist and an avid gun enthusiast, 80% items really interest me. I guess I will need to see how this plays out with our current administration before I delve deeper into this. Pretty sad.

No Executive Orders were filed and aren't likely to be filed right now, only Executive Actions were announced today. We got lots more info: https://pewpewtactical.com/biden-executive-actions-80-kits-braces

Executive Orders are not law!

So I am looking to join the 80% crowd. I have ordered the 3rd Gen gig and 3 80% lowers from "80% Arms. (1 .223 for practice and 1 ea. .223 and .308.

My question is that since the 80% lowers are hard anodized, when I mill them the new surfaces will no longer be anodized, can I, or would it be beneficial to re-anodize the lower?

The anodizing adds approx. .003 in of thickness. Is this enough to make any difference in the fit of these parts. I suspect not, but would like to understand the tolerances impact of having things anodized.

Thank-you

In order to anodize the raw areas of an anodized part, it must be stripped. I advise against it. The only areas worth worrying about would be the trigger pin holes, especially if you remove the FCG occasionally. The inside of the pocket only locates the components. I would have the lower cerakoted. That way, the cerakote will protect the trigger pin and selector switch holes, in addition to the pocket. I have seen preanodized lowers that have the raw aluminum drilled holes and it hasn't affected them. Just keep some gun grease in the holes and you'll be fine.

i am very satisfied with the 5d tac jig i bought . it took about 12 weeks to show up due to the backlog and numbers. there is no plastic in the jig and i was very pleased with the ar-15 lower i milled for my build, however the front pivot pin that came with the kit did not fit any ar-15 lowers i tryed it in. my suggestion is to buy seperately both front pivot pins for the ar-15 and ar-10 for the lockdown points on the jig. i'm curently milling a 80% ar-10 7075 lower, and it's actually a lot of fun now that i have my technique down with with the dewalt dwp611 tool. i give the 5d 4 stars.

why not add juggernaut tactical lowers and jigs to the list. would like to see you guys review them

Do you have any experience with Jugernaut lowers and jigs? I was thinking of getting a few soon.

I have finished one 80% lower with their jig. It was super easy and straightforward, though the holes actually took longer to drill than the milling. Also, one problem was that their video shows drilling the holes straight through, but when I did that, the far end was wallowed out -- pretty significantly. Don't think it's going to affect operation, but it looks bad, and their instructions should show drilling from both sides.

Actually meant for the above comment to refer to 5DTactical's jig -- not Juggernaut's.

Love the juggernaut lowers but I prefer the 5D jigs

Warning to buyers avoid 5d tactical. Their quality has gone down hill, they've added a plastic top plate and other "upgrades" that make their product now worth the money. Also their customers service is nonexistent... I regret buying from them.

Not* worth the money

I get immediate answers to my emails from 5D

This seems a bit more like an ad than a review of the best 80% lowers really . 80% lowers are OK but they really aren't any better than the Modulus or 5D tactical lowers . They're pretty basic Right to Bear Arms has the engraved lowers , blah blah blah there are a 100 companies on the same level as 80% . Really the Andersons are much better lowers for constant Mil spec lowers . Next time maybe actually get some lowers mill them out use them for a while and then form an opinion .

Funny thing is thats kinda what they do! They test lowers AND jigs! Who'd have thunk it! lol

Any update with 80% Arms new Gen-3 release?

When you say "7075 is the standard for “real” lower receivers but the difference in strength is so little that I doubt someone could break a 6061." You're referring to the ultimate tensile strength for 7075-T6 is 83,000 psi vs. 45,000 for 6061-T6? Is that considered "so little"?

In this case, yes. The lower receiver of an AR-15 is not a pressure component or a wear component. It holds the trigger pack and provides threading for things such as the buffer tube and grip. The only places on a AR-15 lower that ever exhibit any kind of long term stress are where the buffer tube housing bends up from the lower and the takedown pin holes.

If your rifle is grossly over gassed and the material of the lower is especially weak, such as with some low-quality polymer lowers, then failure can occur at the buffer tube. However, that is not common. Zytel with 30kpsi is what several brands use in their polymer lowers and it is totally sufficient to handle the stresses required. Zytel being significantly weaker than 6061 Al at 30kpsi Vs. 45kpsi

The concern for an AR-15 lower for durability comes mostly from corrosion and trauma. 6061 Al is more corrosion resistant than 7075 and is easier to work with, both are desirable for an 80% lower since it's common for the lower to not be coated after completion, such as anodized or Cerakoted.

For trauma such as being run over with a truck, dropped, or other accidental happenings that could damage the lower -- there isn't a lot of events that would break a 6061 Al lower that won't break a 7075 lower that people are likely to encounter. The only time that it would really come into play would be if you plan on using the rifle as a crowbar or other intentional misuse.

If I remember correctly the reason the lower was changed from 6061 to 7075 was very simple extended full out use caused the pin holes to start to elongate (IE - become egg shaped) so unless you have a rare unmated DIAS you are using you will never have an issue

Not a bad write up, side note Can't remember the source off the top of my head but the reason for lowers made of 7075 is that the first ones were made of 6061 Military use found that the fire control pin holes were taking a beating and starting to elongate(egg shaped)so the change to 7075 to stop it. Since we poor peons are forbidden to have the giggle switch we really have nothing to worry about

your Uncle Leroy comment, in the immortal words of Mrs. Brown, "that's nice."

Matthew

Just what I needed to make informed decisions.

Very well written and full of expert advice.

Kind regards,

Chuck.

agreed. Thank you Patiot

While will the Easy Jig 2 Multi-Platform only work on GEN 1, .308 lowers? I would like to do a .308 build but I like the features on the Gen 2 and Gen 3. Plus Gen 1 seems to be getting more scarce. What is the reason the Easy Jig 2 won't fit or work on the Gen 2 or Gen 3?

Thanks for your help, and thanks for all this great info!!!

You mentioned the 5D jig what about their 80% lowers?

Buy Modulus Arms, the original. Better prices on 80% lowers elsewhere though.. try ZRtactical.com for great prices on forged and billet lowers.

can you please explain which Modulus Arms jig you are referring to? I have one that I bought about 5 years or so ago, maybe longer. What makes this one better than the new one out from what you know since I have not used one yet, nor converted any lowers? I actually was thinking about getting the new one that Modulus has out, 5D tactical. Any information on which one to buy, or just keep, would be appreciated.

The 80% Arms, Modulus, and 5D Tactical jigs all have one very important "thing" in common: the inventor. If you search patent records, the one name that keeps coming up is Wayne R. Partington. It looks like he worked at 80% Arms first, as he is named as an inventor in patents assigned to them. Then he was apparently involved with Modulus, as he appears as a respondent in a patent infringement action (subsequently dismissed) in the matter of 80% Arms, Inc. v. Modulus Designs, Inc. In my opinion, it's no accident that the Modulus and 5D Tactical jigs look virtually identical as they were apparently designed by the same guy. I'm not a patent lawyer, but it would appear that USP 9,982,958 and 10,145,633 assigned to 5D Tactical would cover the art as presented.

The main difference in the Modulus jig and the 5d ONE is that the Modulus one is a single jig for AR15,AR9 & AR10's where the 5D requires you buy additional parts to do AR10's . Also the Modulus jig has a lifetime warranty that they do actually live up to . Where the 5D has no warranty .

I want to build a .308 LR which 80% should I buy and will it be compatible with any LR.308 upper? Thanks for the help and info.

ANy that say they are compatible w LR/SR (DPMS) 308. SLight mods may be needed. A common one is a little grinding on the "trough" of the bolt catch so the upper doesn't make contact. That is the only mod I had to make on my 6.5 CR. Check out Noreen firearms at onlylongrange.com for both forged and billet 308 lowers.

I have 2 Noreen AR15 80% about to finish, and was looking at their .308 80% - do you like yours and recommed?

Already purchased the Modulus Arms Jig

Can a guy just mill the pocket and trigger hole with a hand drill bits and mill bit?

Can do it with a metal file if you put the work in

I've done them with everything from a cordless drill to the Modulus Arms router jig... TRUST ME, save your $$$ and buy the Modulus when you can. I can turn out a lower in around 30min, less if it's billet. It will take most of a day to do one with a lesser jig and drill.

Great article Matthew! I'm surprised you didn't mention 80-lower.com for their excellent 80 lowers selection. I've purchased their .308, AR-9, and AR-15 80 lowers and have always been thrilled with the quality and fast shipping. I'm actually getting ready to start a 1911 80% and a Glock 80% from their website. 80-lower.com is my go to website for everything for my builds.

I’m surprised you didn’t mention tacticalmachining.com for 80% aluminum lowers or EParmory.com for polymer.

I’ve made many and have never been disappointed with their quality or value.

EP Armory sucks and Polymer in general...just sucks... once upon a time, polymer was MUCH cheaper than AL, so it made sense...for a minute. NOW?? AL 80% lowers are just as cheap.... can be found for $25 at times if you LOOK... I agree.... Tacticalmachining has great lowers at great rpices...but don;t let that get around!! They're already out of stock way too often!! LOL

When you used the Easy Jig, did you use anything for cutting lube? If so, what? I'm wondering how much longer an end mill will last with cutting lube.

Also, what percentage of the cuttings would you say the vacuum was able to catch? Did it keep the pocket sufficiently clear so that cuttings didn't interfere with the progress of the end mill? I'm wondering if it would be better to engineer a way to suck the cuttings out the trigger hole since that would be working with gravity instead of against it.

I prefer bacon grease.... 100% serious.... and the cost is perfect! If not, try just about anything.... I;ve used silicon grease, WD-40, PB blaster.. 3 in 1, cutting oil etc with varying results...but I prefer BACON!!

Why are the 80% AR-9 lowers so pricey? Even the AR-15 80% lowers go for a bit of a premium over the completed stripped lowers unless you buy a blem, but the AR-9s seem to be exorbitant.

A lot of it comes down to volume. AR-15 lowers are cheap because they are being made by the truckload and by 100 different brands. 80% lowers are a much smaller market, AR-9s is an even smaller market, combine the two and you have an incredibly small market that is just starting to grow. These are likely to stay a bit pricey for a while, sadly.

Only 3(?) weeks ago the prices were lower and you had a number of different mfgs listed.... How about listing makers with hot links... competition keeps prices fair and allows buyers to locate the best deals consistent with their skills and tools. I don't have any "spare" change but I got skills, and tools. You had one company listed (before) that offered 3ea milled 80% lowers and their template set with drill guides installed for about $200. That makes $101 ea. at Brownell's more than a little excessive when you add the drill plates. (about $450 total)

The article had not been updated in some time prior to this update, many of the links and prices were outdated. Sadly, we aren't able to create hotlinks for the vast majority of items we cover. I believe Amazon is the only one with the API currently to be updated on the price and availability regularly. We'll add more if the tech presents itself!

Pssst...?? It's because I've been building them with a standard 80% lower and MEAN ARMS ENDOMAG!!! Who wants an ugly skinny little glock mag sticking out of our beloved AR anyway?? Looks like a German donkey d*ick try to mate with my AR!! LOL.. Anyway... Mean Arms Endomag... spring and follower easily converts std Pmag to 9mm... Only 9mm parts you'll need is the barrel, BCG, and Endomag... I recommend the Armaspec SRS-9 buffer as well..

A shop vac adapter that sucks all the aluminium chips. Good luck with that. Your shop will look like a dozen strippers shook their glitter off.

Not at all... It works quite well on the Modulus Arms jig... It helps if you clean up a bit when adjusting the bit depth too... LOL I;d hate to see your shop.. :)

Is it possible to get drawings for those internet dimensions for those of us with smithy mill?

It's possible for you to buy one and copy it, ya dang cheapskate!! LOL..

Hmm. Before reading this article I actually thought I could trust the reviews on pew pew. But this felt to bias. Like any other paid commercial. Where are the other jigs like 5D and a bunch of others. Sad.

Hi Mike, thanks so much for the comments. I can see where you're coming from. The team got really excited at how different the Easy Jig 2 was compared to the old drill press jigs we've used. We'll be updating the article with the 5D and looking to do a hands-on comparison of that one too.

Thank you for your reply, I look forward to see a real comparison between jigs and lowers from more than one supplier.

Hmmm!!! No 5D Tactical...

Re the video where the host is interviewing a guy from Brownells: is the host stoned?

GREAT article - well-explained, BUT - if non-anodized means shiny and not black, how come the weapon in the photo above, identified as "Completed AR15 80% lower, anodized" appears to be NON-anodized?

Opps, that should read "non-anodized"! Thanks for catching that.

Has anyone built with juggernaut tactical for a AR10? If so how were they? I am looking to build a quality 6.5 Creedmoor. Any other suggestions would be appreciated.

used juggernaut tactical 80% lowers and their ultimate jig and it works perfect. great quality easy to use jig for

ar-15 and ar-10 service is good, ship orders right away

I'm trying to find an aluminum lower with the features of the juggernaut tactical or the jl billet ones (which i think look great, though i haven't tried them) but WITHOUT the integrated trigger guard.... And obviously, i want it to be a company that isn't some garage operated cnc with a website... If anyone knows of a company producing an 80% lower with threaded takedown pin/ bolt catch's, flared and broached magwells, upper tensioning screws, and an ambi bolt releases, AND with an open trigger guard PLEASE reply. I want to build a high-end AR and i believe that the features i want shouldn't be out of reach because i want to mill it out myself...

5dtactical has got the best one just my opinion

Aluminum doesn't rust, so scratching your aluminum lower is not going to lead to rust developing.

I use Aluminum Black touch-up pen for scratched and marred areas. This turns aluminum surfaces black without the need for paint. Looks great and no one knows but you.

Only 1 comment/warning - Do Not go to Polymer80!! Have 2 different flavors of their products and neither is properly setup and their jigs are not correct for trigger an/or hammer pin holes. One side on 1 jig was 1/16" off! Closest on 3 jigs is: .009. 2nd, if you clamp their jig onto the 80% and mark out with Sharpie, once you finish machining out FCG you will have a couple problems; 1. cut through on at least 1 side at either trigger or hammer pin region; 2. Opening is not sufficient to properly install trigger/hammer. Also jig piece for trigger hole at bottom is not properly aligned so be gentle. Now onto the main event: A. 556v3 unit - none of the detent holes were drilled and I was not able to find either a 3/32 x 7" or 1/16' x 7" bit to be able to drill out for bolt catch and still have a straight hole. If you follow instructions and jig design, you will have a very, very thin wall or 0 wall for the selector detent. I came up with a solid work around for the takedown/pivot pins and have now even modified my 100% AR to use these. I will try James Madison as I want to have a realistic opportunity to test a polymer lower. I have made many "adjustments" on the Polymer80 products I have and I am now very close to having a G150 finished (ugly but finished) and probably will have the 556v3 finished in another day. I had to use a 1/8" bit to drill for bolt catch and then drill out the bolt catch and make an 1/8" pivot pin and tap the hole to 8-32 and use an allen head set screw. Also, if you take your time, leave more materials than their jig wants, especially at selector detent area, you can use a dremel and gently finish the takedown of materials for trigger, hammer and to make sure detent has plenty of wall. Also be careful of their online PDF instructions (emailed them a month ago now and no changes that I've found) as they leave out important details and they mismark where to and where not to leave materials. Hope this helps you and some of your readers make a more informed decision. I created 2 tickets but only got help with one from Polymer80.

Dang, I haven't tried P80 for anything besides their glocks which were great. Thanks for sharing your experience.

Good. Don't. P80, Glock frames are great. P80, AR15 lowers are garbage. They are an accident waiting to happen. They WILL fail eventually. A polymer lower does not lend itself well to the AR platform.

I have made 3 Polymer80's, and the worse problem I have found is finding the best tool speed. Another source I know bought a carbide milling bit with great success...far better than the tool steel bits that come with the P80. I am fairly handy with spotting and fixing problems, so I can not argue about the problems you have described, but all 3 of mine are sub moa and completely reliable with no indications of any kind of problems or failure. I did go with a trigger upgrade for each rifle, and am very pleased with them. I have heard real good things about James Madison, and might give one of those a go for a winter project.

The lower has ZERO effect on accuracy speaking of the AR15 platform. Only function the lower receiver serves is to hold the FCG parts, basically. Your garbage P80 lowers WILL fail eventually and i certainly hope it isn't at a moment when you need them to defend your life. P80 & all polymer lowers in general are known to fail around where the receiver extension threads into the lower. Only a matter of time. For the author of this article to even include P80 in here is insane. Juggernaut and plain ol' 80% Arms lowers are top notch but most any 80% ALUMINUM lower(Forged or billet) will be fine.

If you purchase a pre-anodized 80 Lower, does the trigger pocket/milled our area need to be anodized after milling?

Yes and no, if you want complete protection then yes it should be. However, since it is aluminum to start with and that area doesn't really have anything that needs to be protected - it is easy to get away without doing anything to it. Generally, I would at least throw a coat of spray paint down there.

to make a 80 % to a 100% the best set up is 5d tactical I know this was about the best 80% lowers but this is the easiest way to get it done and I drop the mic and walk away

Uh, if you buy something that is more than 80% finished, you are buying a firearm. Also, if you have your machinist friend finish an 80% for you and you take possession, you are both in a heap of trouble.

Jl billet best 80% aluminum lower

James Madison best 80% polymer lower

Both offer AR10 and AR15

My 2 cents

Tennessee Arms Co. has an excellent looking lineup of 80% and complete polymer lowers. They've got a threaded brass insert for the buffer tube which takes care of my main worry with poly lowers. I just ordered mine! Should be able to have it all milled out by Christmas.

Since I’m already milling/routing I like to add PDQ levers to mine. Not cheap compared to standard bolt catch but gives you ambi bolt catch/release.

I've used 80%arms Gen I jig and 80%arms billeted lower. I love them! FYI, use masking tape and tape a shopvac to the threaded buffer tube port while milling. Thank me later;)

Never used one but 80percentarms has nice looking billet lowers in AR15 & AR308. I used their new Easy Jig Gen 2 & a router to do my 80%s. Also can get New Frontier Armory style AR9 & AR45 80% lowers now. I have one of each laying around waiting to be built over the winter. The Easy Jig Gen 2 can supposedly do them all.

Another cool looking billet 80% maker is Juggernaut Tactical. They offer their lowers with ambi bolt release.

Yup, looking to get my hands on an Easy Jig Gen 2 in the new year!

Interesting you didn’t mention Juggernaut Tactical. Their 80% is loaded with features and are billet, so they’re nice to look at too.

Hmm, haven't heard of them yet, thanks for the rec.