There’s nothing like assembling your own AR-15 lower receiver for personal satisfaction and customization.

I’ll guide you through everything with minimal tools and tons of tips I’ve learned the hard way!

So get ready for A LOT of pictures that will make building your lower a breeze. Plus a bonus of the upgrades I immediately did to my lower to make it perfect for 3-Gun competitions.

But first…a disclaimer that this is for educational use only. If you don’t have the right tools or experience, please have this done by a professional or buy a completed rifle (Best AR-15 Buyer’s Guide).

Table of Contents

Loading…

Parts and Tools

Parts

I went with a California featureless build so there’s the funky looking grip. But otherwise, everything is pretty standard.

I haven’t found much difference between lower parts kits and buffer tube assembly’s as long as there are decent reviews and not a no-name company:

- Anderson stripped lower receiver: Also check to see what your local gun shop has to avoid shipping and extra fees.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

- Anderson lower parts kit ($75)

- Mil-Spec Buffer Tube Assembly ($60)

- Bravo B5 Stock ($60)

Tools

- Punch Set ($15): I prefer brass so you don’t mar up your lower receiver and it’s good for lots of other gun stuff too

- Long Arm Hex Key Set ($12): You’ll be using hex keys or Allen wrenches in a lot of installations. Go with the long arm versions for extra reach.

- Hammer ($10): I like the rubber/plastic ends instead of standard steel since there are very few times when you actually need that much force…also if you use it directly on gun parts, you will not mar the finish

- C-Clamp ($10): Not super necessary but useful to install the trigger guard, 4-inch should be good

- AR-15 Combo Tool ($20): Good for installation of the castle nut, but more useful for upper receiver builds

- Utility Knife ($7): Needed for the pivot pin installation

Alright, let’s get onto the actual build!

Magazine Catch Assembly

You can start your AR-15 lower receiver build many different ways but I like knocking out some of the easier ones first for quick wins.

Find these three parts along with your lower receiver. The magazine spring is the largest width spring in your kit.

Place the magazine release spring into the hole shown above.

Place the magazine release button on top of it with the serrated side up.

Press in the magazine release button and flip the receiver over to start threading in the magazine catch.

It might be a little tricky the first time you do it since you have to maintain decent pressure on the button to make it flush against the receiver while matching up the threads. Righty-tighty!

Make sure the catch doesn’t scrape against the raised portions of the receiver.

Once you have it threaded slightly you can release the pressure and rest your fingers for a little.

Then get ready to do it again!

Press down the magazine release even further into the receiver past the flush line and tighten the magazine catch a couple more times.

Check once in a while.

Here you can see that there’s a gap between the mag catch and the receiver when you’re pressing the mag release button flush.

You’ll need to tighten more or else the mag catch could fail to go back into the receiver during a reload.

This is a good distance where the magazine catch will not leave the receiver unless somehow you manage to really smash in the magazine release button.

You can test with some of your mags to make sure it catches and releases.

Congrats! You’ve installed the first section of your AR-15 lower receiver.

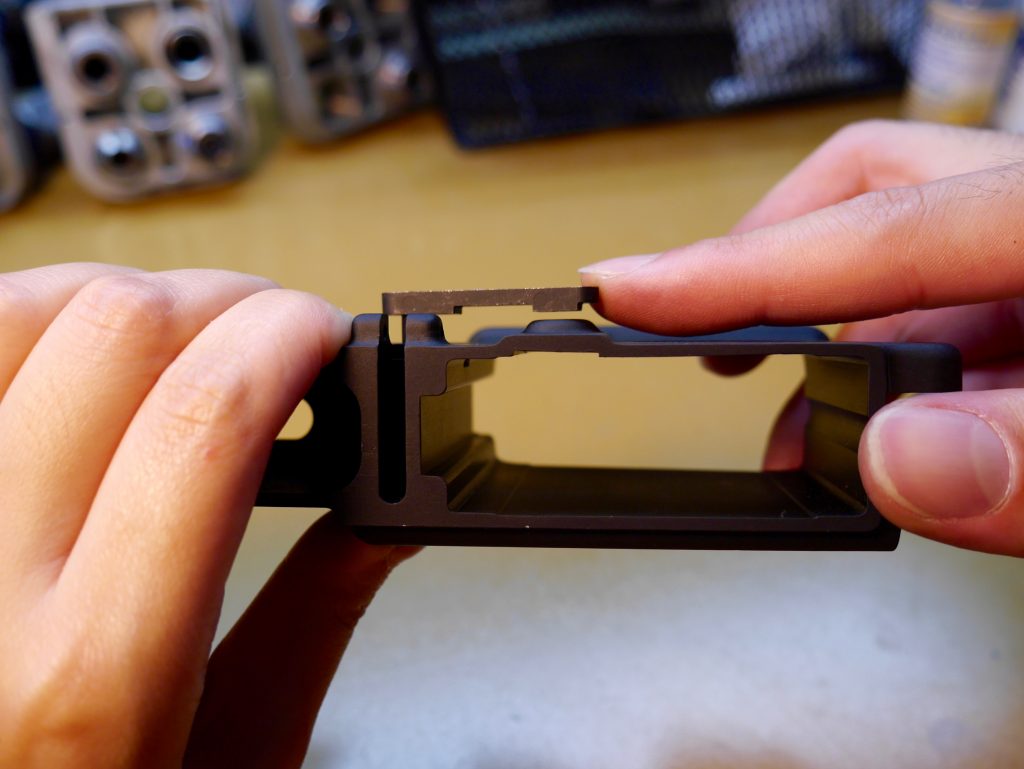

Trigger Guard Assembly

Some lowers have this part as part of the stripped lower…but most likely you’ll have to do it yourself.

Find the trigger guard and the longer roll pin.

Depress the pin of the trigger guard which will be closer to the magazine well.

Don’t worry, the two sides are differently sized so you can’t mess it up. Then just slip it in.

Sometimes I find that the other side has a hard time dropping in so I lightly press down or even use the plastic hammer (lightly) if it’s slightly more stuck.

Make sure everything is lined up for the roll pin.

You can either start it with the hammer, with a punch, or just with your fingers. I like using the hammer to get started then using the C-Clamp below.

It’s much easier than trying to hold down the receiver while hammering.

Note: If you decide to go with just hammering…make sure you are supporting the dog ears or else they can pop off pretty easily even on a good quality lower.

I did end up marring my finish a little so I would heavily suggest using some plastic. (I’ve heard a little piece of milk carton plastic between both sides of the clamp will do wonders.)

On my installed trigger guard, you can see a little damage to the finish. But I know I’ll be dealing a whole lot more damage to the receiver at the range and during competitions.

Bolt Catch Assembly

Find these parts!

The bolt catch spring is even throughout while the other remaining smaller spring is fat on one end for the disconnector.

Place the spring on the plunger and drop it into the hole above the magazine latch.

Orient the bolt catch like above and drop it down.

You will need to depress the bolt catch for everything to line up. I like using a hammer and punch to get it started.

Apparently, there’s a special tool to clamp the roll pin but I decided to make my own.

However, it wasn’t protective enough so I would suggest wrapping your pliers with tape first then some cloth. Or you can just continue using the punch all the way through.

The finished bolt catch with just a little bit of marring.

That wasn’t so bad, right? The trigger coming up is a little tricky but don’t worry, I got you!

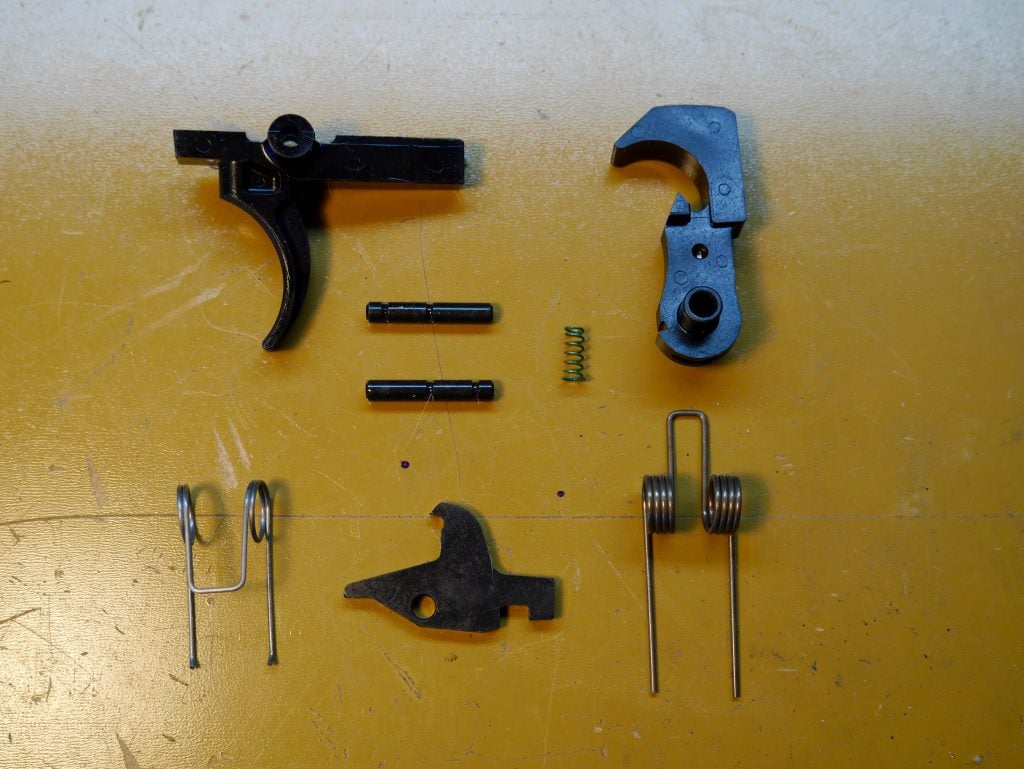

Trigger Assembly

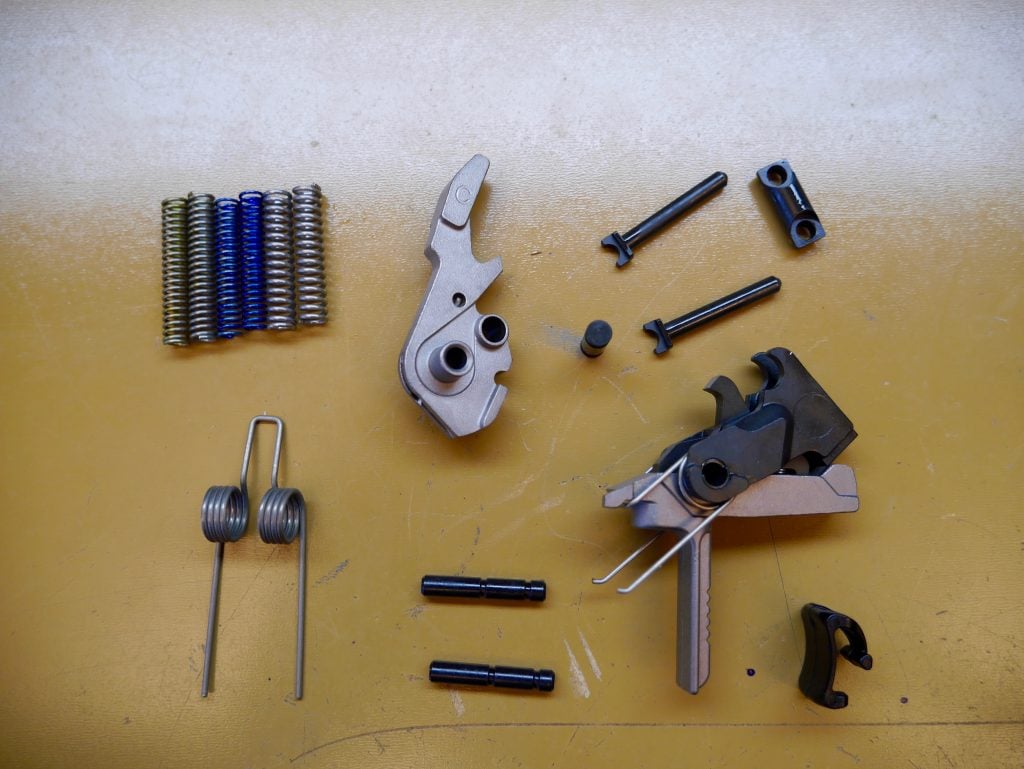

Pick out these parts from what’s left.

Attach the springs according to what you see above.

Place the fat side down into the trigger so that the spring stays put.

Place the disconnector onto the spring.

Press down on the disconnector to see the trigger hole. You’ll be placing this assembly into the receiver and then putting a pin through it.

Place the assembly so that the trigger goes through the oval bottom of the receiver.

Match up everything so that you can see the clear hole for the pin.

I sometimes find the trigger pin has some trouble once it’s almost through. So, I resort to using a brass punch after matching it up.

Here you see the fully installed first trigger pin.

Double-check the placement of the hammer and spring. Make sure the springs lay on top of the first trigger pin.

They’ll be decent pressure to align the second trigger pin hole.

Once you get the trigger pin halfway through, I like cocking the hammer down so that it eases the pressure a little bit.

It turned out extra stiff so I used the brass punch.

Here’s the installed trigger assembly.

Resist the urge to dry fire!

Doing this will release the hammer which has nothing to hit except the lower receiver. And enough of that will start to damage it.

I hold the hammer down with my other hand so that it slowly releases instead of slamming into the receiver wall.

And there you have it…the trigger assembly!

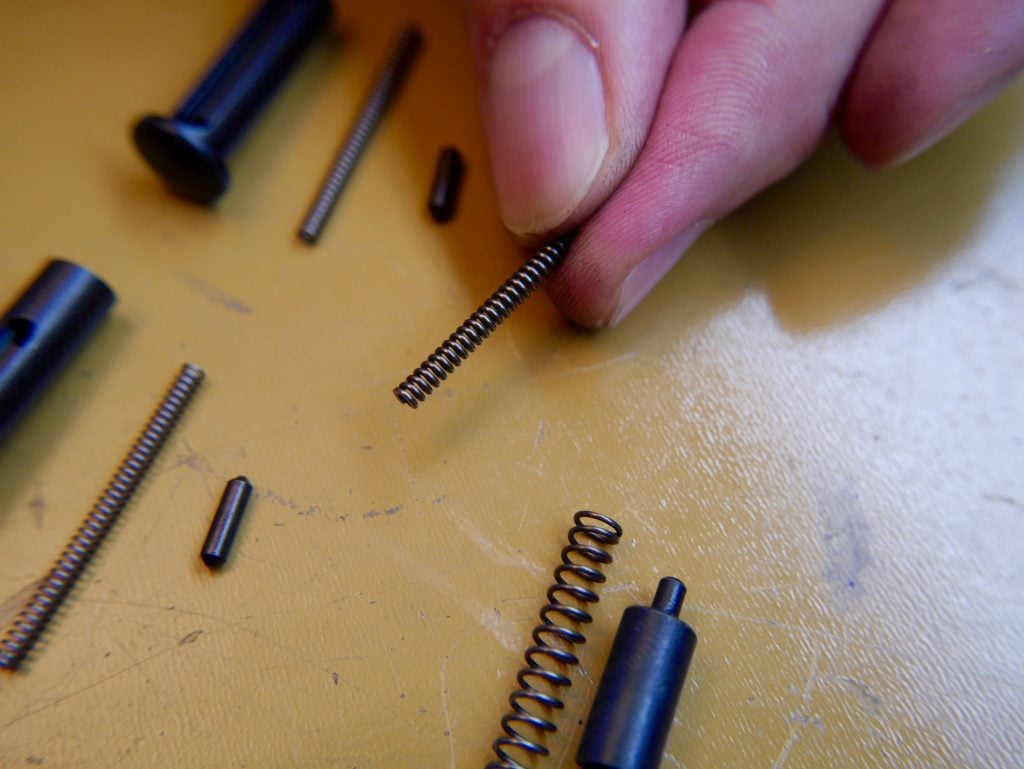

Safety, Takedown Pin, Grip, & Receiver Extension

Still with me? We’re in the home stretch now.

These should be the remaining parts in your kit. Note the different sizes of springs relative to each other. The two skinnier longer ones are identical for the takedown and pivot pins.

Let’s start with the grip.

The top one is a normal pistol grip while the bottom is the CA legal Hammerhead grip.

Both have holes for a screw and washer. You might just need a longer hex key for the pistol grip to reach all the way in.

But first, let’s cock the hammer back so it opens up the safety selector hole.

Insert the safety selector.

Set the position to “Fire.”

Find the safety detent (pointed side into the receiver) and put it in the hole on the opposite side of the safety indicator.

A much better view of the silver safety detent installed.

Find the safety detent spring. It’s the thinner one that is slightly shorter than the other identical thin springs.

Insert it into the hole at the top of whatever grip you’re going to use.

Sometimes the grip doesn’t fit on easily (nor do you want it to be loose). I find that using a big flathead makes it easier to slide onto the lower receiver.

Match up the spring with the safety selector hole and double-check that the safety selector is still in the “Fire” position on the opposite side.

Screw in the grip with the enclosed hex nut and washer.

Look for the shorter pin (rear takedown pin) which will have an identical spring and detent to the longer pin (pivot pin).

Install the rear takedown pin from the left to right (shown fuzzily, sorry!) and also place the detent in the back of the receiver.

It helps to orient the takedown pin so its “channel” will accept the detent.

Insert the detent spring.

Now find the buffer retainer and spring (thickest one left) and place them in the hole above.

Also, take a look at your end place where one side has protrusions that will fit nicely with the back of the receiver.

But first, screw on the castle nut in the position above. With the bigger square cuts toward the back of the lower receiver.

Then put on the end plate in the correct orientation. I’ve definitely done this in the wrong order, so please learn from my fails!

Start screwing in the buffer tube. The end plate will move with each turn and start messing with the spring.

Try your best to not let it come out.

When you’re almost done screwing in the buffer tube, take a break to look at the other side.

You want to stop right before the buffer tube reaches the buffer retainer.

Perfect fit with just a little bit more of a turn.

Now you need to match up the end plate with the receiver and also make sure that when the plate is tightened that it will hold the spring.

Start screwing in the castle nut with your hands first.

If you have an AR-15 armorer’s tool, it will have a section to tighten the square cuts. I’d heavily recommend that since it’s only a few bucks.

But otherwise, you can also just lightly punch it tight.

You can also “stake” your castle nut where you use a center punch to smash in the end plate into the smaller cuts of the castle nut.

I would recommend testing out your lower a lot beforehand since it’s annoying to undo but really keeps it together. Also, make sure your end plate allows staking.

Now find the last pin, screw, and detent that will be for the front pivot pin.

Place the detent spring in first.

Followed by the detent.

Time to whip out the pliers and utility knife to hold the pin down flush against the receiver since you’ll be sliding the pivot pin over.

I’d recommend doing this in a sideways cardboard box or something above you to catch the potential flying detent and spring if you mess up. Also, you might want some eye protection.

Insert the front pivot pin over the knife blade with the channel facing where the detent will spring out. This will install the pivot pin.

Ta-dah!

Now find your stock and buffer and buffer spring. Yes, it’s super ugly but I got it since it was the cheapest “color.”

Insert the buffer spring in.

The buffer end will orient like the above.

Slide on the stock until it doesn’t move easily.

Pull the adjustment tab out and continue moving the stock inwards. You can now use the adjustment tab to select your preferred distance.

And YOU’RE DONE!

Unless you’re in CA and want to pin your stock, then check out my How to Pin a Collapsible Stock Guide.

But if you’re like me…you want to make your AR-15 lower receiver the best it can be. Here are the upgrades I added immediately.

AR-15 Lower Receiver Upgrades

JP Silent Captured Spring

The JP Silent Captured Spring is one of the best upgrades to make your AR-15 feel like a pellet gun! It takes away the *sproing* of the traditional buffer tube and drastically reduces recoil.

If you’re going with a lighter BCG, I’d recommend getting it with the additional springs so you can truly tune your gun. Otherwise, the stock spring works great.

Check out how to Install & Tune the JP Silent Captured Spring in our article.

Ambidextrous Safety

An Ambidextrous Safety is useful especially when you’re running a CA featureless rifle, but if you’re a lefty it’s critical.

For tips, see How to Install Your Ambi Safety.

Magpul BAD Lever

The Magpul BAD Lever is on every single one of my lower receivers. It makes manipulating the bolt super easy from your right hand.

Install it in less than 5 minutes.

Hiperfire Trigger

Swapping out the trigger is probably the best upgrade you can do to your AR-15.

The Hiperfire Trigger is a new single-stage trigger that has no perceptible creep, little reset, adjustable weights (I run mine at the lightest 2.5-pounds), and actually increases the hammer strike power.

One of the weaknesses of other triggers is that while you can get light pulls, those sometimes can lead to light primer strikes too.

See my in-depth review. The installation was also much easier than I expected given the number of parts.

Conclusion

I know it seems intimidating but building your own AR-15 lower receiver doesn’t have to be scary. With this guide and the right tools, you’ll be ready to rock your AR-15.

If you need more help in building your lower or your full AR-15 for that matter, check out Brownells’ series How to Build an AR-15 Tutorial.

How did your first AR-15 lower build go? Let us know in the comments below. And pair this guide with our How to Build an AR-15 Upper Receiver and also check out the Definitive AR-15 Resource for even more upgrades, optics, etc.

174 Leave a Reply

This was a really helpful guide for a noob!

Glad it helped! Thanks for reading!

Very helpful thank you. I now have a new hate for roll pins however. I had the tools, the parts, and knew generally where everything should go, but as this was going to be my first build that was more than just slapping an upper on a lower it was nice to not be guessing. The tips for the roll pins saved a lot of time but they are still a headache to install. I managed to mostly avoid any scratches too. I would have to point them out or you might not notice them. It really was not that bad, and after doing it once I likely will only build from now on. At least when it comes to lowers. Still need to try doing an upper one of these days.

Roll pins will be the death of us all! Lol. I share that hatred as well but I am really glad that the guide was helpful!

Best of the best

Rear Takedown Pin- "Right to Left"

What a great product! Been a newsletter subscriber since the Covid scam and you guys at PewPew never cease to amaze. Thank you for sharing

holy what not. . I didn't have a punch set available (have one now) but that trick with the pliers is just. . super awesome. not having the bolt catch installed was driving me insane.

I've found that a metal banjo finger pick is the perfect tool to hold the detent in for the front pivot pin.

If you build more than one lower, I highly highly recommend the Wheelers pivot pin install tool. Once you do it, you will never use anything else. I have built more than a dozen lowers for myself and friends and this tool is one of the most useful tools in my collection of lower build tools. It also has a starter punch to install the trigger guard pin. It claims it has a starter for the bolt catch pin but the wheelers 2 piece tool set they sell for that specific task works much better and risks less scratching.

The hammer part was too glosses over, I had to go to youtube

Can Pew Pew Tactical do a visual AK 47 parts kit build guide (like this one for the AR’s) and best tools guide for AK builds in the future?

I just build my first lower receiver build. Instructions were fine but I ran into a problem. Once the hammer is fully cocked, it won’t fire. I checked the spring configurations and they seem fine. The only way to release the hammer is to press down on the rear of the disconnector which then “clicks” and then pulling the trigger. Amy thoughts on what could be happening?

Thanks, I just successfully built my first AR, and everything works...so I am thrilled. I had a good idea what I had to do, but wanted to be sure, so this helped a lot. Again, thank you!

Congrats on the first build!

Here's another THANK YOU for this guide. I purchased 2 kits for myself and my Daughter. We followed this guide with the only real hassle we had was the trigger pin installation. I resolved this by cutting a 16D nail then using the point to pull the pieces into alignment. I installed the pin by using it to chase the nail through and out of the receiver. The balance of assembly went without issue except for a couple of flying detent pins and springs.

Thank you very much for this guide. I referred to it constantly in building out my stripped lower. (Then later when I replaced the trigger/hammer group.)

Excellent guide. I'd add that a set of vise-pliers is insanely useful, and that a buffer pin isn't absolutely necessary. (Complete coincidence that I came to that opinion after I launched the pin into orbit...)

I don’t know where I got the instructions to build my first lower, but these were a good reminder for the second. I can do it in about 40 minutes now.

Alternate tips/thoughts:

A spring grip clamp can hold the bolt catch down when installing the roll pin if necessary.

Punches about the same diameter of any pin hole are your friend. A small punch can be used to seat and align the pinned trigger parts and bolt catch when installing pins.

No brass? Wrap your punches in electrical tape. For starting the bolt catch roll pin I take a punch about three times larger than the pin and wrap it in electrical tape (the business end) with a little lip of tape hanging off the end and it can be used to protect your lower while driving the roll pin in, and the lip stops the punch from slipping off the pin.

I have a Wheeler piviot pin installation tool that works great, but your method seems pretty fool proof too.

My parts were coated in some sticky protective coating. I acetoned all of them before installing.

Grease in the pivot and takedown pins helps them function.

If you have a buffer tube with a cut-out for the buffer retainer pin, if you tighten the tube on too far—where the pin still engages, your upper might not seat, so check before cinching down the castle nut.

Thanks for the tutorial, I was able to build my 1st lower and subsequently built my 2nd one an hr later. Your step-by-step method is great, and I didn't have to spend any additional dollars on tools. I had everything laying around the house. Thanks again!

Great write up!

Your article is quite helpful! I have so many questions, and you have answered many. Thank you! Such nice and superb article, we have been looking for this information about How to Build an AR-15 Lower Receiver. Indeed a great post about it!!

Thanks a lot! This was awesome. Only thing that was a little unclear was how the hammer installed above the trigger. No picture showing that. Took a little trial and error, but finally got it.

Installation of the hammer was omitted.

Great instructions! Put together my first build with only minimal tools. Very detailed instructions that help out a lot. Only thing I wanted more coverage on is the trigger assembly as I had to go to another video to see which way the hammer spring had to sit on top of the trigger pins. But other than that awesome!!!!

Hello! I would like to share my instructional video I know images can be difficult but if anyone is struggling with their lowers or would like an in-depth guide and tutorial with a matching template Here it is! We sell two models a holding template instructional video with or without the parts kit! Over 1000 Units Sold today. Google Us! Bkollar Templates and use code: freeship2023 at checkout

The wording for installing the takedown pin is wrong. It installs right to left. Even though I know better, I was just following along without thinking as much as I should. Having to redo that detent and spring madness after you figure out you did it wrong is pretty frustrating. Otherwise, this was a great build guide. Just did my second lower build and other than the aforementioned mix up, this was helpful to have while I did it.

I'm currently in the middle of my first AR pistol build and this guide is amazing. I build my lower from YT videos, but most do not go into detail on which spring and facing of components. I was able to verify I assembled my lower correctly.

I went with Aero enhanced receiver and parts kit. This has a lot of set screws vs roll pins, which I found very handy and much simpler than I anticipated to assemble. Now the lower is assembled (although I will be removing some set screws to locktite them), I have an Aero buffer tube coming with Geissele Super 42 combo with H1 buffer, braided spring, and two tungsten weights to go H1-H3. I'll be purchasing the SBA4 brace to complete the lower.

I'm still researching which upper caliber I'll build for my home defense. I'm considering 300 Blackout, 223 w/ 110 grain cartridges, 22LR or 22WMR, and 5.7 home defense (if the AR Five7 company ever begins manufacturing the 10" again). Speer has some interesting options for the 223 and 5.7 specific for home defense. Any suggestions are appreciated.

Thank you, your instructions are great. Put together my 1st AR all black and I'm super happy to say with zero Mark's, scuffs or scrapes. Thanks again for your expertise.

So, I've built several lowers....and I always have this page open because it's awesome AF. Thanks, y'all!

This was helpfull for my first build. Only thing is i kinda had to back track a bit to get the upper on but after messing around with it i figure out how it goes. Over all i did get my ar15 built! Thanks

Eric, many thanks for this indepth walk-through! I only lost one detent pin, follow your advice as much as I could. A painless (relatively) effort!

Ordered a single point sling with the piece that goes behind the end plate ...don't know the name...so I thought I would take the buffet tube off....lol..not knowing bout the springs and parts that would fall off. So thank you Eric for the tutorial.

Great article! Just finished my first lower build… aside from mixing up a takedown spring for my safety spring, it went without a hitch. Fixed my mistake, threw my existing upper on to check function, it’s rock solid. And was a lot of fun, too. Thanks!

I almost always replace the pivot and take-down pins with extended pins. That leaves me with the stock pins contained in most LPK's. I use the stock pivot pin inserted from the left side, and rotated groove forward, to hold the retainer and spring in place. Then just butt the extended pin's end against the 'helper' pin's end and push it into place.

I've also found when doing this that it helps to have the extended pin started with the groove facing forward and once it is through the near-side lug I then rotate it until the retainer pin drops into the groove.

HTH

Hello i found that using a small zip strip arond the trigger assembly to get it alined drop it in line it up put the pin in no messing with the 2 parts cut the zip strip and take it out

first time build.....very helpful....great detail.....could use more close-ups.

Thank you very much for the great, and easy to understand, tutorial.

I just finished assembling my first lower and it was really a breeze! I will be going back and making mods per some of the other replies.

Again, thank you for this,

Randie

Thank you the the detailed pictures and instructions, youtube videos don't have the close ups that needed for this.

1 get a cnc billet lower from primary arms or joe bob outfitters - they just look cooler and the bolt catch pin is a threaded allen screw - super easy to install

2 get a razor blade and dull it down on the sidewalk and use in combination with an allen wrench the same size as the front takedown pin for installation of it - the razor blade holds the detent pin and spring down while you slide the allen wrench in from the opposite side and then just push it back with the takedown pin and it snaps right into place

3 get a starrett center punch for staking the castle nut theyre 9 bucks on amazon and super easy to use

There's a lot of super useful info here, well organized. A couple of suggestions for updating the pivot and takedown pin installation process:

1. Just use a specialized pivot pin installation tool, especially for the front pin. It only costs about $11 at Walmart online and it will make the job a snap (and save you the cost of at least one emergency replacement parts kit). Every time you build an AR (or help a friend build one) you will be glad you did. Best $11.00 I have ever spent on gun tools, hands down.

2. Cut about 1/4 to 1/2 inch off the takedown pin spring, especially for the rear one. This is doubly important if you use an Aero lower (or any brand that uses a set screw to secure the takedown pin spring, which adds even more compression). The standard length spring just pushes too hard on the detent into the takedown spring groove, and makes it really hard (damn near impossible, actually) to push out the pin with just your fingers.

3. Use a little 1000 grit sandpaper on the head of the takedown pin detent, and in the takedown pin groove. And some grease in the groove of the takedown pin. Again, this makes the takedown pins work a whole lot better.

Or even cheaper, use a 1/4 inch clevis pin and a 1/16 inch pin punch instead of special tools

I was looking for this because that was exactly my experience with 3 aero lowers. That rear takedown pin detent spring was just too long and I needed to trim it down. I'm using the Juggernaut Tactical Hellfighter mod kits and you need to turn that rear takedown pin. The new takedown pin also has a section cut out and too much pressure makes the detent skew the pin if you aren't super careful.

I believe the description for installing the rear take down pin is incorrect. It says to install the pin “from the left to the right.” It should be installed from the right to the left - assuming left/right are looking at it as you would shoulder the weapon. The photo shows it correctly with the head of the pin on the right side of the receiver.

Thanks for your excellent tutorial! I'm doing my first AR build and actually I'm finding it pretty simple. I build hot rod big Harley motors and scratch build custom bikes to put food on the table. A tip that may help others from losing small parts is to work on a piece of short knap carpeting or even a sheet. Also pre fit trigger and hammer pins in your lower, then for the final install, wiggle the hammer and trigger into full alignment and the pins will easily push in position with your fingers. As far as other roll pins, sometimes a number drill bit the same size as the pin OD can be used to enlarge the hole the first 1/4 into the ear. This will let the pin locate perfectly and prevent slips, gouges and damage to the lower. Also start pins in the first ear before installing the part to be pinned, it's much easier.

I got an Aero LPK for 50 a couple months ago. Shop around!

Just used this on my first lower. Thanks for the guide. The hardest part overall was the trigger guard pin, followed by the upper takedown pin spring. I didn’t listen to your advice and ended up losing one but thankfully my parts kit had a spare. As a total noob the hammer orientation wasn’t clear to me so I had to fall back to a video to get that part working.

Awesome experience for me to have this kind of guide for a noob like me. Thank you very much.

Does the trigger disconnector ever need to be filed down at the bottom to get the pin to go through if it does not line up with different receivers and different disconnectors?

No, it just needs to be lined up correctly which can be a pain.

You just helped me put together my 1st ever lower receiver in 2 hours or less. This was absolutely great, thank you.

great details on assembly the AR-15. I like the detail that you've provided step by step. Awesome work.

Thank you for giving complete instructions, that are understandable

thaanks for the help.

im a techy guy, but this was beyond my scope when it come to assembling a rifle.

now i know how.

the beat tutorial video

Thanks, just completed my first lower. Not having the exact tools, I found a few things that helped. Built on an Anderson lower using an LBE lower kit. The biggest issue (probably for all) was the roll pins. I used a Vise Grip 5WR (5 inch) which is one of the smallest to hold the pins. I lined up the pins right on the edge and used my hammer to strike the Vise Grips to start the pins. Once everything was lined up, I used an Irwin 7 inch clamp. Great tool, Rubber coated jaws, but I removed the one against the roll pin. Since they are plastic, it did not mar the lower, but provided plenty of power to push the pins. Only other thing was installing the hammer. I lined up the holes and inserted a small punch which helped when setting the Hammer pin. Better than trying to push the hammer down with one hand and trying to set the pin.

I've used this for 3 lowers. Works perfectly every time. USE a plastic hammer head. Thanks Eric!!!

Best step-by-step I’ve seen. Well written, fully inclusive, and insightful. Thank you for sharing. I highly recommend it to anyone looking to build an AR-15.

Great help! Just built my first AR pistol! Had a bugger of a time getting the hammer retainer pin through but not your fault. My only confusion was the install of the buffer retainer. It isn’t shown well in the photo and I had to look around a while and zoom in on a subsequent photo to see which way the pin cap went on the spring. But I did figure it out and it is obvious once you see how it goes. Now I plan to try it out tomorrow if there is a dry spell before or during the forecast rain. Thank you!

Great article! I just built my first lower using your instructions. My only suggestion would be to add some more detailed pictures on how to install the hammer, and how to poison the hammer spring inn side the lower. I had to search for a YouTube video to help me with that portion.

Built my first AR15 pistol today using your DIY guide. Its a gift for my wife so it was really important that I didn't screw it up so I appreciate all the help and pictures provided. Thanks again. Its turned out great!

appreciate this article, was super helpful and accurate.

Thanks for a great step by step lower build, I just finished 2 lowers and your instructions were spot on .

Awesome! Have fun shooting them :D

Just built my first AR-15 and the step by step instructions were great. Thank you for the information!

This was my first build and I went with an 80% Polymer lower so a few things were subtly different but overall went very smooth. A perfectly functional if cosmetically imperfect AR-15 with some great upgrades for 1/2 the cost of an over the counter unit. I was a little skeptical I'd be able to build one from scratch but I'm glad to say 2 months of methodical research, purchases and lots of time on this site has led to one of my better achievements. Cheers and thanks for all the helpful info. Keep up the good work.

Thanks. All went well, only on trip to the gun shop for an extra spring. One had to run away.

No torque wrench needed for castle nut? Just snug it on tight with an armorer's wrench and be done with it, correct?

Also, I don't stake my castle nut either so is it really necessary to torque it to 40 ft. lbs. like some recommend?

Can you please email me the PDF so I may print the instructions without all of the internet adds?

Thank you!!

Our articles aren't available as PDFs, sorry.

I am about to assemble my first AR and this is such a helpful resource! The clear language and crisp photos make the task much less daunting!

Best step by step I’ve ever read/seen! Super useful, easy to understand steps, and very well taken pictures. Just about as good as having a friend walk you through it in person! Many thanks!

Thanks for your tutorial.

I have built a few ARs over the years but, appreciate your input to avoid mistakes and "buggering" my receiver !

Thanks, Eric! You've been my go-to resource for all things AR since getting back into this a few months ago!

I used this article last weekend on my first lower receiver assembly.

Your clarity was super helpful and I really enjoyed myself.

The rifle performed wonderfully.

I used takedown detent on bolt catch because the youtube guys go so damn fast and don’t show shit clear ugh. This made it so clear gotta go to gun shop now. Thanks for being clear as day. Seriously I was like wtf is going on lol

I used this guide to put together an AR15 lower from parts. Thanks for the help!

When assembling and installing the trigger, disconnect and spring(s) it makes the job much easier if you use a temporary pin (which can be cut from an old drill bit), which will be driven out by the actual trigger pin during installation. That way you only have to line up the hole in the trigger with the one in the receiver instead of trying to line up holes in three pieces while fighting two springs.

Wow !!’ That had to take a lot of time.

Very helpful.

Thank you for your continued great work.

I assembled a lower using your instructions last night. It was very helpful to understand the order things needed to be done. Thank you very much!

Three things that I noticed:

You said: "Install the rear takedown pin from the left to right (shown fuzzily, sorry!) and also place the detent in the back of the receiver. "

1. Just like the front takedown pin, the rear takedown pin goes from the right to left, not left to right.

2. Don't put the detent or spring into the rear of the receiver yet. Instead, screw the buffer tube almost all the way in to the correct position, but with the castle nut backed off. Then, insert the detent pin, followed by the spring. Hold the spring down and rotate the buffer tube until the receiver plate covers the spring. That way you only have to hold the spring in place once, instead of each time the buffer tube and receiver plate go past. It makes it much easier.

3. For the front takedown pin, use a small punch to compress the spring into its recess, then place the point of a safety pin or heavy straight pin through the hole in the side of the receiver. The pin will hold the spring in place while you drop in the detent making it really easy to start the front takedown pin. Once the front takedown pin is in place pull the straight pin out and rotate the front takedown pin until the detent snaps into place.

Great and concise guide, THANKS!

This is a great guide, it made assembly of the two lowers I finished a snap. With one exception. The bolt catch pin installation. It's OK, but there is an easy way to do it using simple DIY tools. See Joe Pleczynski's method at https://www.youtube.com/watch?v=8-6YW81-T4o

The key is the bent wire tool that holds everything in place with the holes aligned. Anyone with wire and two sets of pliers can make it. The size doesn't even have to be very exact, Any solid wire between 1/16 and 3/32" diameter will work, the 3/32" being the perfect size

You can get away without it, but if someone has finished the lower from an 80%, they know enough and have the tools needed to make his pin holding punch. But even without it, protecting the lower with masking tape and just getting the pin started holding with with needle nose pliers until it is in far enough to hold itself works OK. It is much easier and less risky for damages than the method you describe.

Even so, this is probably the best and most comprehensive photo guide available. I did a lot of looking online before I started my assembly and there is a lot of great info, but its often fragmented. Yours is complete. Do a second edition with lubrication info, alternative methods for bolt catch and maybe pivot pin, maybe trouble shooting and it truly would be THE definitive guide to lower assembly. And I don't mean that in the usual hyperbolic sense but that it really could be a gold standard. You could probably even sell it as a print formatted pdf. Some of us still like to have a manual to lay out in front of us. Videos are nice at times, but a good photo guide is easier to get the big picture of how things go togethert and are better references for going at your own pace,

Regardless, thank you for making this one. I was able to assemble with ease the components from PSA lower parts kits into two tactical machining 80% lowers I finished.

Great instructions and pictures went together real smooth thanks

First time putting one together. Great instructions and pics - made it a snap.

Thanks for sharing!

awesome! thank you!

First time builder along with my son (age 11), we had a blast! The instructions and pics led us through with no problems. Finished the lower and we are both looking forward to more. Until I acquire my upper, we will take down one of my other guns, oil it, reassemble and shoot with it. I think we found a new hobby to enjoy!

Awesome! Thanks for letting us know, always nice to read these kinds of stories :D

Great write up with outstanding directions. Found a clever hack for the front pivot pin install on AR15.com not long after my first build when the spring and pin went flying and I had to wait two days for parts ;-) Run down to your local hardware or big box store and buy a 1/4" clevis pin, the kind with holes, not the ball bearing type. Costs less than a dollar and works like a charm.

Better to get a set of roll pin punches from Brownells instead of using the c clamp.

Thank you for the step-by-step...excellent job and much appreciated. Get out of California...life's too short!

Thanks for the great instructional. I could of put most of the darn thing in my sleep in the 70’s but was a challenge today especially with my fat fingers. Would of never made it without your tutorial. Just wanted to build an old M4 n PSA had a great little put together lower. Thanks again n I use a lot of your videos

Excellent writeup, I am about to do this myself and this is a million times better than watching an hour-long youtube video.

Which featureless grip is that on your gun and how do you like it compared to the Thordsen stocks? I'd rather pin my stock and use that grip than buy a featureless on my next AR15 so it looks better and is cheaper to build.

Thanks again

Eric used the Hammerhead grip for this article, I like featureless grips and a pinned stock a lot better than the Thordsen stocks. They are easier to install and uninstall, give more options, and look a lot less...featureless.

We have a complete review of a huge range of Featureless Grips that you'll want to take a look at! Personally, I like the Resurgent Arms and Strike Industries Megafin best.

Thanks! Finally got my lower out of jail and am assembling it now. It's just like legos with your guide. I ended up going with the Sparrow Dynamics grip, it looks pretty similar to the Resurgent Arms grip on the featureless grips guide.

Wonderful assembly guide, with awesome pictures which made the steps easy to follow.

One thing folks might want to consider when installing the front pivot pin is the trick using a 1/4" Clevis pin and something narrow enough to compress the detent spring (youtube video on this here - https://www.youtube.com/watch?v=XJNaTjvQaVQ). You should be able to find Clevis pins cheap at a local hardware store.

Definitely the way to go. I had some one-hole aluminum clevis pins left over from an old external frame backpack, and made an insertion "punch" from a piece of coat-hanger with a loop on one end that I could leave attached to the clevis by its split ring when not in use, and have the whole little kit all together. Not pretty, but works fine.

Actually, if you have a piece of 1/4" aluminum or brass bar handy, or even a wooden dowel, you can also easily make your own pin if you can drill a hole.

Thanks! Great job! Perfectly walked me through assembling my first AR.

Glad we could help!

Thanks. Good article.

do you have video of how to change the AR9 buffer tube to a stock AR15 buffer tube assembly and adjustable stock ?

AR9 and AR-15 should use the same buffer tube, but the weight might differ depending on your AR9 setup.

great job, well done

Thank you. Just finished a project. I did not say that. I am not here

Definitely appreciate the step by step. It was a great write up. Some of the steps could use a "this is how you know it was done right" kind of thing if you are ever considering a version 2.0. But thanks again!

Thank you! Very detailed and informative. Lucky for me I had a drop in trigger so it made it alot easier.

I die a little inside every time I see a featureless grip on this site

Great write up!!

wish you had PDF File of article, love it great photos and detail

Thanks, great write up, Eric! Super set of pics, everything a builder needs.

Boy that CA hammerhead grip is ... unfortunate. Yeesh.

You can avoid aggravation—and a frustrating bent or lost spring—by waiting to insert the rear takedown pin, detent, and spring until the last 1/4 turn of the buffer tube / end plate screw on step. You can use the razor trick there, too.

Thanx for the build directions, Bradda! AWESOME!

Did a 308 lower with ease because of your tutorial. Good details and pics. Great job dude, thanks.

What type of oil/grease do you use during assembly?

Just used your instructions to put together my first AR. Great job. Couldn't have been easier. Thanks!

Just put together my first lower. Your instructions made it super simple. Thank you for the help. Keep up the awesomw work. God bless.

Two corrections: "Install the rear takedown pin from the left to right" is backwards. Pin goes right to left. Second, there are various instances of "end place" instead of "end plate."

Thanks for the great content.

Built my first ever multi-caliber Anderson lower. I used the Anderson build kit with the 440 stainless-steel trigger. Your instructions and photo layout made it very easy to complete my lower.

Awesome! Glad we could help. Have fun!

Eric! You rock! First AR lower build (Anderson). Your step by step instructions made it almost too easy. Thanks for this and all your reviews. Read them regularly.

You're so welcome, Steve!

Thanks for the great instructions! I had no problems setting roll pins using an old diesel generator trick when putting the giant nuts and bolts together. The day before, I put the pins in the freezer (still in the plastic bag to prevent inducing moisture, though 1 day shouldn't be an issue). It shrinks the metal enough that they were snug, but I had no problems at all.

Great instructions fellas! First build tonight with a PSA 5.56 NATO 10.5" pistol kit with Magpul grip, PSA lightweight 10" MLOK handguard, and SBA3 brace. Machined two 80% lowers earlier in the day. BEAUTIFUL pistol! Your directions were spot on and the only trouble I had was when I temporarily lost the buffer retainer and spring (Yep, I backed the buffer tube off and forgot too watch the retainer)! Thanks for the great instructions. Made the job easy. Cant wait to get out and get it on the range. One more build to put together sometime in the next few days, but it will be even easier than this one I'm sure.

Side note, Pew Pew Tactical is an every day must read now. Thanks for all of the great advice and reviews.

Hi Sean, so glad we could help out!

That was my first lower build and you made it a breeze! Everything works great and I owe it all to you Mr. Hung! I'm very impressed how easy it was with your instruction and pics. Thanks a lot, always reading all your reviews which I really value.

So glad we could help out!!

gotten to everything no problem up to the hammer. trying to get the pin into through to hold it in place but the J Hook is in the path of the pin and wont let it go all the way through. how do i fix this problem?

Just put together my first lower (Anderson), used your pics. Slightly different order as I did a rifle stock with a Luth MBA-1 and a Rock River National Match 2 stage trigger. All went well, didn't time it as I did it slow and easy. Did notice what you said on a couple didn't match the pics, I went with the pics!! But Thanks.

Now waiting for my 22" Radical .224 Valkyrie upper from Primary Arms. Bought the lower local for $50, most everything else from Primary. All shipped correctly and fairly fast considering I went with cheapest shipping.

I need some help.... Looking for any suggestions. I mistook the buffer assembly spring for the bolt catch assembly spring, rushing and wasn't paying enough attention (first build give me some slack). I was overeager and well she's in there good. seems like theres a lip keeping it in there. Any thoughts on how to get that out of there? I hope I haven't wrecked my build entirely. This is such a frustrating situation.

Very small pliers or a dental hook. Rip the spring out, don't try to save it. Just get it out. New spring will cost you a dollar.

Thanks David, I was thinking the same. I don't care if it is salvageable I just want it out. I already priced a replacement, no issue buying one. I was thinking of filling the port with some olive oil or something to help ease it out. Might do the trick. So frustrating, lesson learned for sure.

Oil might help but I don't think it will, your problem isn't so much friction as just X is larger than Y.

If you go with an oil use something with a lower viscosity than olive oil, Remington Oil would be my pick if you have it.

Good luck!

David, problem solved. Used some CLP, and a drywall screw. teeth on the Drywall screw grabbed the spring when lightly threaded. Pulled it right out! Again thanks for the info!

Awesome! Glad it worked out mate.

Excellent job guys! I used this today while assembling my first lower and I never had to leave the page! Thanks for all your help and information!!

Glad it helped! Always good to know when we've helped a new AR builder finish their first one!

Great tutorial! Just finished a pistol 458 socom, couldn't have done without your tutorial. I do recommend a drop in trigger though.

Thanks for the tutorial. Great pictures. Easy to follow. Took less than 20 minutes on the first build. Keep up the great work.

First AR15 build. Your steps were easy to follow and straight. I had about 6 hours into it and looks really good. Thank you for the step by step.

You're so welcome, Mark.

P:robably the best lighting and camera work on AR15 build.

Thanks Claude!

Probably the best lighting and camera work in any UTube videos on AR15 build.

Your Trigger Hammer spring is on backwards in the picture

Thanks for posting this! I hate roll pins ;)

Just finished my build this was a great guide. Thanks

Would you please talk about lubrication?

How do you feel about pre-lubing the parts for protection before assembly?

What parts do you feel require lubrication?

I clean the parts to get preservatives off, and put a super light film of oil over the parts before assembly.

First ever lower build and it was done in under thirty minutes! Thanks for a great guide!

You're so welcome, Steve!

just finished my first custom build, and thanks to you and your site it went flawlessly.

much respect and appreciation.

michael

Thanks so much Mike!

Great instructions. Used this from start to finish and didn't scratch the gun at all. Was a lot of fun and gives you the knowledge to find problems later on. Thank you.

You're so welcome Vincent!!

I really like your site. I have downloads the Upper and Lower build and am going back over boat to see if I need to download more info from each area, I am a beginner, I have done some trigger installs and other things using You tube and that has worked for me in the past. I like your and will use it later on a 14.5 inch barrel build I am planning.

Very nice presentation of the work being done. Simple,easy to understand. Thanks for your work

You're welcome Roe!

Great job man, this is my go to.. I know how to build after 5 builds but always open this page for the brain farts. Thanks for taking the time to lay this out for all to access.

You're so welcome!

I didn't do as good a job as Jim, above, don't work well on my lap.

Took it out to my leather shop, . . . put it on the table, . . . 90 minutes later it was good to go. Made one mistake, didn't screw the stock on far enough, lost the spring for the buffer stop.

But all in all, . . . thank you for a wonderful and very informative video. Made my "first lower" very easy, . . . and only a half dozen scratches (that's good for me), . . . lol.

May God bless,

Dwight

You're welcome Dwight...and we all have some dings/scratches on our first...or even 10th.

Excellent presentation. I read it all, dumped out parts and followed along. I did it in my lap with no special tools. It functions well and zero scratches. (Anderson lower and parts kit)

Thanks...Jim

GREAT DETAIL- MAKES ASSEMBLY A SNAP. THANKS TILL THE NEXT ONE..

Glad we could have helped!

Just finished my third build. I didn't think I could build an AR, I always thought it would be super complicated. But after doing alot of research online and finding PewPew Tactical. It became very easy.

Thanks alot. This is definitely my go to place for all my future builds.

So welcome Felix!

Tons of experience with the M4 / AR 15 platform. Never build one. Your instructions made my build quick and easy. Thanks keep up the good work.

Thanks so much Brian!

Thank you for the awesome how to, I just finished my first lower, easy to follow and understand.

Very useful, and helped me put together my first lower. However, there is a mistake. The hammer spring is installed correct in the "Correct Trigger Spring Orientation" photo, but then you flipped it on "Orientation of Trigger Hammer". I had my spring according to the second picture and the disconnector wouldn't release the hammer when letting off the trigger. Flipped it around and now it works perfect.

Just finished assembling my AR lower using your photos. I've lots of experience shooting and field stripping AR's, but never assembled one completely. It was very simple thanks to your photos.

Thanks.

You're welcome, Mike, glad I could help out!

I recently had an issue with the buffer retainer. Removing and replacing it was simple. My question is, the retainer doesn't move like I thought it should, and the buffer spring pops just does what it wants. So, should the retainer move up and down? Having feed problems, jams, etc. The bolt no longer locks open. Any info is appreciated.

Hey Tom, I'll try to help but you might want to get it looked at by a gunsmith. The retainer should stay up to keep the buffer/spring from flying out, but be able to be pushed down whenever you want to manually remove the buffer/spring.

Why would you put a "featureless" hand grip to make a compliant rifle but then use a collapsible stock which makes it non compliant?

Hi Tim, I went with a blind pin and epoxy route on the stock to make it fixed (http://www.pewpewtactical.com/pin-collapsible-stock/). I like the length and cheekweld of the stock more than the truly fixed ones.