Are you looking for the best 1911 pistol on the market?

We researched dozens of models and tested a bunch ourselves to find the best options. Finding the perfect gun can be tricky, especially with all the models available, so we’ve done all the digging and testing for you.

To make this list, the 1911 had to be a model that we would recommend to our friends and family based on price point, features, and reliability.

Using those metrics as guidance, we used our collective experience with thousands of rounds and hundreds of hours with 1911s in hands-on reviews, shooting events, and guns from our own personal collections to create this list.

There is something for everyone on this list, including a range of prices. We’ve tested loads of 1911s from Double-Stack 1911s, Affordable 1911s, 1911s in 10mm, and 9mm 1911s.

THE QUICK LIST

-

Best Overall 1911

-

Best Budget 1911

-

Best 9mm EDC Option

-

Best 1911 for Concealed Carry

-

Best Semi-Custom 1911

-

Best 10mm 1911

-

Best Target 1911

Table of Contents

Loading…

How to Pick the Best 1911 Pistols

When evaluating which 1911 pistol is right for you, there are a few factors to consider.

Purpose

First, what is the purpose of the 1911. A home-defense 1911 can be slightly bigger than a 1911 that you intend to carry. You might want a larger capacity out of your home gun and be willing to downsize for a concealed carry 1911.

Nailing down what you want to use it for will help direct you in narrowing down the size and capacity you need.

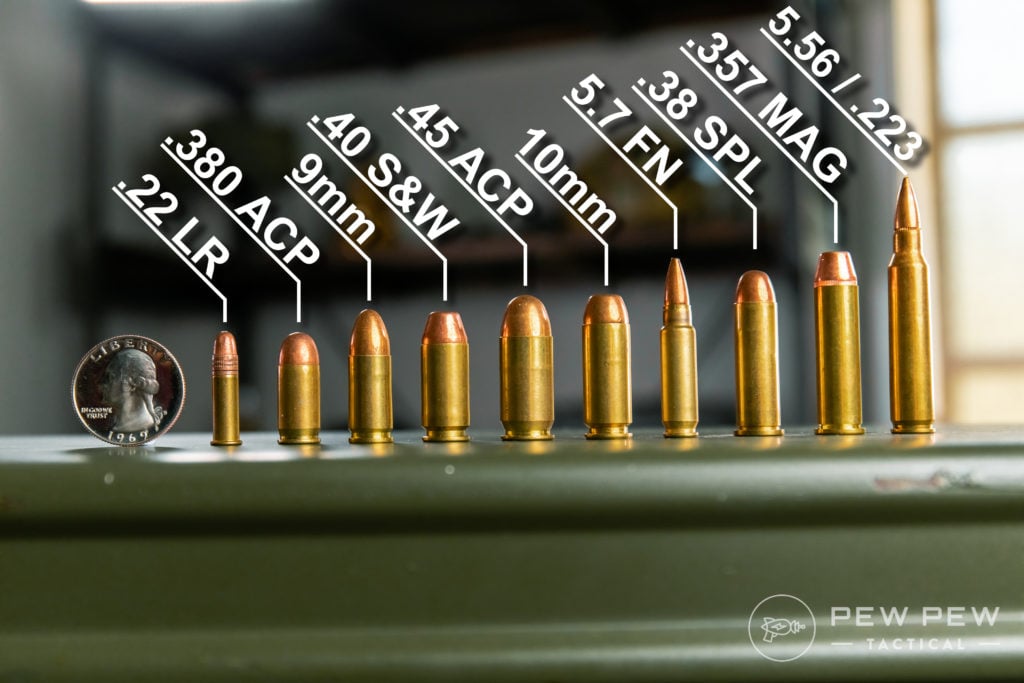

Calibers

Most 1911s come in either .45 ACP, 9mm or 10mm, with 9mm and .45 ACP being the most popular calibers.

A 10mm is great for hunting but is a bit much for everyday carry. .45 ACP is a classic choice, but it might be too powerful for those with weaker hands or newbies.

9mm is a great choice due to the availability of ammo, but some might prefer the traditional .45 chambering. Again, narrowing down the caliber will help guide the model selection.

Our tip: unless you want a 1911 for a very specific purpose like hunting, choose one that uses the same caliber you shoot or train with the most. That makes buying ammo easier.

Magazine Capacity

You aren’t going to get the same capacity out of a 1911 as you would a Sig P365, but you still want to keep that in mind as you are choosing.

If you don’t mind carrying a spare mag or two, then a 1911 with a slightly smaller capacity won’t be an issue; however, if you don’t like to EDC a lot of extras then you might want to opt for something with a higher capacity.

Features

Sights, grips, controls, triggers…all of these are also things to keep in mind while shopping and can add or take away from the value of a 1911.

Some 1911s come with standard three-dot sights, while others make it fancy with fiber optics. Swapping out sights can be a pain, therefore, it’s often times it’s easier to get the model you want with the sights you prefer.

Same for grips. Grips are easier to swap out than sights but if you’re not a DIY’er, it might just be worth the added cost to get a 1911 with grips that suit you from the jump.

How We Test 1911s

We’ve shot thousands of rounds and spent hundreds of hours with 1911s between our hands-on reviews, shooting events, and guns from our own personal collections.

All hands-on gun reviews at Pew Pew Tactical adhere to a strict testing protocol.

That includes 500 rounds through every review gun. For each gun we hands-on review, we test with both FMJ and JHP ammunition and a couple of magazines to evaluate accuracy and reliability with different types of ammo and magazines.

We shoot 5-round groups and 5 and 7 yards and use a pistol rest for at least one round of fire to eliminate shooter error.

All 1911s are evaluated based on their hits on target, ability to reliably fire, ergonomics, and overall value.

See the details of this in our By the Numbers section below.

Best 1911 Pistols

1. Springfield Garrison – Best Overall 1911 Pistol

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Great accuracy

- Gorgeous finish

- Reasonably priced

Cons

- Bluing is thin and can be scratched easily

- No front strap checkering

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.6″

- Width: 1.25″

- Height: 5.5″

- Weight: 37 oz

- Capacity: 7+1

Features

- Stainless or hot salt-blued finish

- Skeletonized hammer and trigger

- Low-profile 3-dot sights

- Extended beavertail

- Ambi safety

- One 7-round magazine

A relatively new entry into Springfield’s lineup, the Garrison has quickly become one of the best-value 1911s on the market today.

The Garrison features either a stainless or gorgeous hot salt-blued finish, a 5-inch match-grade barrel, low profile 3-dot sights, backstrap checkering, and an excellent trigger.

When you pick up a Garrison, you feel like you are picking up a $1500 1911, not a $750 one. They are available in 9mm and .45 ACP.

If you are looking for a beautiful pistol that won’t break the bank with the shooting chops to match, this is the one.

Take a peek at our hands-on review of the Springfield Garrison!

2. Tisas 1911A1 US Army – Best Budget 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Affordable

- Forged frame and slide

- Classic styling

Cons

- GI sights are period correct, but tough to use

- Can be hit or miss with certain hollow points

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.5″

- Width: 1.29″

- Height: 5.75″

- Weight: 39 oz

- Capacity: 7+1

Features

- Forged carbon steel frame and slide

- 70-series internals

- Turkish walnut grips and plastic grips included

- 5″ cold hammer-forged barrel

- Two 7-round magazines

The Tisas 1911A1 is the clear frontrunner when it comes to budget 1911s.

Why? For starters, it uses forged frames and slides, and all other parts are machined out of steel. No cast or MIM parts here with the sole exception of the recoil spring plug.

Another shocker at this price point is the finish. Every example we’ve got our hands on looked good and had evenly applied coating that gives it that old-school Parkerized look. Even the wood grips have been pretty.

Tisas also wisely elected to go with minimal branding on the gun for a cleaner mil-spec look.

These are completely forged and machined, reliable, good-looking, and affordable at around $350-400. On occasion, these even dip as low as $299!

Be sure to check out our complete review!

3. Springfield Armory Ronin EMP 3″ 9mm – Best 9mm EDC Option

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- 9mm-specific frame

- Reduced grip circumference

- Concealable

Cons

- No front strap checkering

Specs

- Caliber: 9mm

- Action: Semi-auto

- Barrel length: 3″

- Overall length: 6.6″

- Height: 4.8″

- Weight: 24 oz

- Capacity: 9+1

Features

- Stainless steel, match grade, fully supported, ramped bull barrel

- Fiber optic front sight, tactical rack white dot rear sight

- Dual captive recoil spring with full-length guide rod

- Aluminum alloy frame

- One 9-round magazine

Next up is one for the concealed carry crowd, the 9mm Springfield Ronin EMP 3-inch.

EMP stands for Enhanced Micro Pistol. So what does that mean? It means that this gun isn’t just a .45 ACP 1911 that has been rechambered and chopped — it was designed ground up to be a 9mm carry gun.

The frame, slide, firing pin, firing pin spring, extractor, ejector, trigger, plunger tube, plunger tube assembly, grips, and magazine are all unique to this model.

These parts mean you get better reliability while also offering other bonuses, like a reduced grip circumference for enhanced comfort and concealability.

I own an older pre-Ronin Springfield EMP 9mm 1911 and have shot a lot through it.

As far as reliability goes, there is almost none better. Since I’ve had it in my possession, I’ve not had a single malfunction, which is more than I can say for many other guns.

It has also displayed good accuracy out of the 3-inch officer-sized barrel, grouping well at distances out to 15 yards, even when rapidly fired.

Check out our full review of the Springfield EMP 1911.

4. Smith & Wesson SW1911SC E-Series – Best 1911 for Concealed Carry

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Lightweight alloy frame

- Bobbed frame for concealability

- Feature-rich

Cons

- Alloy frame means more recoil

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 4.25″

- Overall length: 7.95″

- Width: 1.3″

- Height: 5.6″

- Weight: 28.8 oz

- Capacity: 7+1, 8+1

Features

- Scandium alloy frame

- Tritium night sights

- Round butt carry contour grip

- Extended beavertail and ambi safety

- Includes one 7-round and one 8-round magazine

For those looking for an excellent mid-sized carry 1911, check out the 4.25-inch commander S&W 1911SC E-Series.

The E-Series 1911s depart from your standard steel or aluminum frame in favor of a lighter scandium alloy frame.

Other great features include tritium night sights, unique fish scale front and rear slide serrations, checkered front and backstraps, ambidextrous thumb safety, and a rounded butt for added concealability.

These features, combined with the commander-length barrel, make this one of our top picks for those serious about using a .45 ACP 1911 as an everyday carry gun.

5. Springfield TRP – Best Semi-Custom 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Semi-custom performance

- Various models available

- Flared magwell

Cons

- Grip texture is extremely aggressive and may hurt over long strings of shooting

- May have a small break-in period

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 4.25″ – 5″

- Overall length: 7.9″ – 8.6″

- Height: 5.5″

- Weight: 27.3 oz – 39.2 oz

- Capacity: 7+1, 8+1

Features

- Stainless steel, match grade, fully supported, ramped barrel

- Two-piece flared magwell (non CC versions)

- Forged carbon steel frame (non CC models), forged aluminum alloy frame (CC model)

- Tactical rack 3-dot tritium sights

- Bobbed carry contour frame (CC model)

- Extended beavertail and ambi safety

- Three 7-round magazines (CC model), three 8-round magazines (non CC models)

We recently got our hands on a batch of new model Springfield TRP 1911s. Suffice to say, we were impressed.

If you really want to get as close to a true custom gun without spending $2000-4000, the TRP lineup is worth a look.

The hand-fitment on these guns is super-tight, like a custom gun. You may find these require a small break-in period.

However, these guns are feature-rich. Excellent sights, great triggers, ultra-aggressive grip texturing, crisp controls, and front serrations are standard. Depending on the model, you also can get accessory rails, a flared magwell, or a bobbed frame for concealed carry.

The TRP line traces its lineage back to the FBI Hostage Rescue Team pistols made by Springfield Armory, and you can see that by the way the perform on the range.

We reviewed four different TRP models, so be sure to check out our review!

6. Colt Delta Elite – Best 10mm 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- 10mm performance

- Reliable

- Good accuracy

Cons

- Railed model costs more

- No front slide serrations

Specs

- Caliber: 10mm

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.5″

- Height: 5.5″

- Weight: 35 oz

- Capacity: 8+1

Features

- Low-profile Novak white dot sights

- Black polymer grips with integrated Delta medallion

- Skeletonized hammer and trigger

- Two 8-round magazines

If you live in an area where four-legged creatures are a threat, enjoy hunting with a handgun, or just like the 10mm cartridge for self-defense, Colt’s freshly revised Delta Elite may be what you’re looking for.

The venerable 10mm outperforms most other self-defense cartridges for semi-automatic weapons. While it is a bit more expensive to shoot, it is quite versatile if you reload your own ammo.

Please keep in mind that if the .45 ACP or .40 S&W recoil bothers you, you’ll need to stay away from 10mm, because it’s even snappier.

For $200 more, you can get a Delta Elite with a Picatinny rail that allows you to mount a light or laser below the 5-inch barrel.

Want more 1911s in 10mm? Check out our separate article.

7. Dan Wesson Pointman PM-45 – Best Target 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Fully adjustable rear sight

- Outstanding accuracy

- Excellent trigger

Cons

- Can be difficult to find in stock

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.75″

- Width: 1.45″

- Height: 5.5″

- Weight: 41.3 oz

- Capacity: 8+1

Features

- Fully adjustable rear sight, fiber optic front sight

- Tactical hammer and skeletonized hammer

- Long K-style trigger

- Inverted, serrated rib and forward cocking serrations

- Two 8-round magazines

Dan Wesson is well-known in the 1911 community for making some of the best pistols out of the box without having to spend a fortune on something like a Wilson, Ed Brown, or Les Baer.

We already covered a decent amount of GI-style, tactical, standard, and carry-oriented 1911s, but what about pure target shooting?

The Pointman 45 is set up just for that, thanks to its fully adjustable rear target sight and longer K-style trigger.

An outstanding trigger, fiber optic front sight, extended beaver tail, checkered front and backstraps, and stainless steel frame with trigger undercut round out the entire package.

No more deciding between trying to drift your sights with a special tool or using Kentucky windage when your point of impact shifts with different. A few simple turns with a screwdriver and you are back in business.

If you want a gun that can put tiny groups downrange with minimum fuss and look good doing it, this is your guy.

8. Wilson Combat CQB Lightrail – Best High-End 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Top-shelf build quality

- Accurate

- Reliable

Cons

- Expensive

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.7″

- Height: 5.6″

- Weight: 41 oz

- Capacity: 8+1

Features

- High-ride Bullet Proof beavertail grip safety

- High-cut checkered frontstrap

- G10 starburst grips

- Battlesight with fiber optic front sight

- Contoured magazine well

- Two 8-round magazines

If you have the coin and want the absolute best, go with the Wilson Combat CQB.

Wilson Combat is synonymous with 1911s and high-quality parts. Many people seeking to upgrade their guns or just have quality magazines turn to Wilson.

I’ve built a couple of 1911s and always come back to Wilson parts. Every time I didn’t, I ended up junking that part and bought Wilson.

For me, the CQB has it all…the Wilson quality, rails, aggressive grips, fiber optic sights, accuracy, and reliability.

It took me a while to take the plunge on a gun this expensive, but I can say it was well worth it.

9. Rock Island Armory 1911 Standard FS -Budget Runner-Up

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Extended beavertail

- Ambi safety

- Affordable

Cons

- Cast frame

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.5″

- Width: 1.42″

- Height: 5.51″

- Capacity: 8+1

Features

- Skeletonized hammer and trigger

- 3-dot sights

- Parkerized frame and slide

- 70-series internals

- One 8-round magazine

Rock Island Armory has long been the universal go-to for affordable 1911s that run well. These guns are designed by Armscor and manufactured in the Philippines.

The company offers a ton of models at great price points. But since we already have an affordable GI-style gun with the Tisas, we chose the Government-style Standard FS model here.

Upgrades over the GI model include 3-dot sights, an extended beavertail, a skeletonized hammer and trigger, and an ambidextrous safety.

Not only are these solid guns out of the box, but they can also be a great base that you can customize and upgrade over time.

Want to see how Rock Island Armory guns run? You can read our full review of the GI model here.

10. Fusion Freedom Reaction – Best Overall Value

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Excellent value

- Feature-rich

- Solid accuracy

Cons

- Checkering may be too aggressive for some

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.5″

- Height: 5.5″

- Weight: 39.5 oz

- Capacity: 8+1

Features

- Sure-Grip front and rear cocking serrations

- Beveled magazine well

- Tuned power style extractor

- Extended safety and beavertail

- Target crowned barrel

- One 8-round magazine

Fusion Firearms was founded by the former president of Dan Wesson and has been producing frames, barrels, and parts for 1911 builders for a while.

They have recently expanded their line of production guns, and that includes the excellent Freedom Reaction.

These pistols come extremely well-fitted and feature aggressive front strap checkering, front cocking serrations, target-crowned muzzles, and excellent triggers.

Typically, a 1911 with all of these features combined would cost twice as much, making Fusion guns true sleepers and absolute value buys.

11. Springfield Armory Mil-Spec – Best Classic 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Solid slide-to-frame fitment

- Classic styling

- Reasonably priced

Cons

- GI sights are period correct, but tough to use

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.6″

- Height: 5.5″

- Weight: 39 oz

- Capacity: 7+1

Features

- Forged frame and slide

- Match grade stainless barrel

- Fixed combat 3-dot GI-style sights

- Parkerized finish

- One 8-round magazine

Springfield Armory makes excellent 1911s, so it is no shocker to see them already make the list twice in such a short span.

So you want a mil-spec 1911 for fun but don’t want to explain to your friends why your foreign-made one is such a value buy — we get it.

Sometimes, you just want a known-good name on the side of your gun, and the Springfield mil-spec offers just that.

This is a gorgeous A1-style firearm that is available in stainless steel or a classic parkerized look. The fit is excellent, and the finish is well done in a way that won’t cause any hangups.

Our editor’s parkerized version of this gun has been 100% reliable with OEM mags, even with lighter reloads. Despite the GI sights being tough to use, the accuracy of his gun has been outstanding.

12. Les Baer Premier II – Most Accurate 1911

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pros

- Guaranteed accuracy

- Top-shelf build quality

- Fully adjustable rear sight

Cons

- Expensive

- Hard to find in stock

Specs

- Caliber: .45 ACP

- Action: Semi-auto

- Barrel length: 5″

- Overall length: 8.5″

- Height: 5.7″

- Weight: 37 oz

- Capacity: 8+1

Features

- Beveled mag well

- Baer deluxe Commander hammer and sear

- High checkered front strap

- Tuned action

- Low mount LCB adjustable rear sight, Baer dovetail front sight

- Two 8-round magazines

For those looking for a true custom-grade 1911, the Les Baer Premier II might be the gun for you.

Les Baer has been a powerhouse in the 1911 world for decades and is well-known and well-respected as one of the finest pistol makers in the industry.

The Premier II is no exception. The barrel is hand-fitted to the slide, and the slide is hand-fitted to the frame. When you combine these premium parts with the crisp Les Baer speed trigger, you get a gun guaranteed from the factory to shoot 3-inch groups at 50 yards.

By The Numbers

Our 1911 pistol finalists were rated side-by-side for accuracy, reliability, ergonomics, and value. We made our rating assessments after testing and evaluating at the range. When rating, we used our standard metrics to determine the most suitable rating from 1-5, with 1 being the lowest rating and 5 being the highest rating.

Accuracy

Accuracy refers to how often shots land on target. We know this can be somewhat subjective for shooters, but to eliminate as much user room for error as possible, we look at whether the gun hits where it intends to with little to no issues with most ammo brands.

We rate based on a scale of 1-5, where 1 represents that the gun shoots unpredictably, experiences unacceptable levels of accuracy (i.e., 12-inch groups at 7 yards), experiences keyholing, or is very particular about ammo.

| Accuracy Rating | |

| Tisas 1911A1 US Army | 4 |

| Rock Island Armory 1911 Standard FS | 4 |

| Springfield Armory Garrison | 4.5 |

| Fusion Freedom Reaction | 4.5 |

| Springfield Armory Mil-Spec | 4 |

| Springfield Armory Ronin EMP 3″ | 4.5 |

| Smith & Wesson SW1911SC E-Series | 4.5 |

| Springfield Armory TRP | 4.5 |

| Colt Delta Elite | 4 |

| Dan Wesson Pointman PM-45 | 5 |

| Wilson Combat CQB Lightrail | 5 |

| Les Baer Premier II | 5 |

Reliability

Reliability is the gun’s ability to fire and cycle properly. When evaluating, we look at how often the 1911 is able to perform both functions and if there are any features that might reduce its ability to do so.

Again, we rate on a scale of 1-5, where 1 represents a malfunction rate of 50% or more of the gun experiences trouble feeding.

| Reliability Rating | |

| Tisas 1911A1 US Army | 4.5 |

| Rock Island Armory 1911 Standard FS | 4.5 |

| Springfield Armory Garrison | 4.5 |

| Fusion Freedom Reaction | 4.5 |

| Springfield Armory Mil-Spec | 5 |

| Springfield Armory Ronin EMP 3″ | 5 |

| Smith & Wesson SW1911SC E-Series | 5 |

| Springfield Armory TRP | 3.5 |

| Colt Delta Elite | 3.5 |

| Dan Wesson Pointman PM-45 | 5 |

| Wilson Combat CQB Lightrail | 5 |

| Les Baer Premier II | 5 |

Ergonomics

For ergonomics, we evaluate how the 1911 feels and fits in our hands while gripping and shooting it. We look at the length of the grip, texture, placement of controls, and whether the style of grip will fit most hands.

Scores range from 1-5. A score of 1 represents an extremely uncomfortable grip due to shape, size, or texture or controls that are placed in a way where they cannot be safely used. A rating of 5 means the 1911 fits like a glove and is comfortable for over 75% of shooters with easy-to-use controls.

| Ergonomics Rating | |

| Tisas 1911A1 US Army | 3.5 |

| Rock Island Armory 1911 Standard FS | 4 |

| Springfield Armory Garrison | 4 |

| Fusion Freedom Reaction | 4.5 |

| Springfield Armory Mil-Spec | 3.5 |

| Springfield Armory Ronin EMP 3″ | 4 |

| Smith & Wesson SW1911SC E-Series | 5 |

| Springfield Armory TRP | 4 |

| Colt Delta Elite | 4 |

| Dan Wesson Pointman PM-45 | 4.5 |

| Wilson Combat CQB Lightrail | 4.5 |

| Les Baer Premier II | 4.5 |

Value

Finally, value is determined based on how much the user is getting in terms of features versus cost. Overall price tag is weighed against the 1911’s specs, features, and performance.

A score of 1 would indicate an extremely high price tag with little to no features and a mediocre to low-performance level, while a score of 5 would see excellent features paired with great performance at a good price point.

| Value Rating | |

| Tisas 1911A1 US Army | 4.5 |

| Rock Island Armory 1911 Standard FS | 4 |

| Springfield Armory Garrison | 4.5 |

| Fusion Freedom Reaction | 4.5 |

| Springfield Armory Mil-Spec | 4 |

| Springfield Armory Ronin EMP 3″ | 3.5 |

| Smith & Wesson SW1911SC E-Series | 3.5 |

| Springfield Armory TRP | 3.5 |

| Colt Delta Elite | 3.5 |

| Dan Wesson Pointman PM-45 | 4 |

| Wilson Combat CQB Lightrail | 3 |

| Les Baer Premier II | 3 |

Why Trust Pew Pew Tactical

Our experienced team of gun reviewers is run by Editor-in-Chief Jacki Billings, a member of the Society of Professional Journalists, ACES: Society for Editing, and the Professional Outdoor Media Association. Jacki has her bachelor’s degree in Journalism and has worked as a media professional for close to 20 years, specializing in gun media for almost 10 years.

She uses her extensive professional journalism and editing experience to set testing protocols and editorial standards. Jacki is a pistol girl at heart, with most of her gun time spent behind handguns, including 1911s. During her career, she has tested and shot dozens of 1911s which has given her the ability to quickly and efficiently evaluate 1911s.

The lead researcher and reviewer for this article is Wyatt Sloan, Jr. Editor. Wyatt is an NRA-certified instructor with previous experience as a USPSA competitor. Wyatt personally owns over 200 firearms and has 10 years of home-based FFL firearm sales. Among his collection are many 1911s. He has used his extensive experience with 1911s and firearms at large to test 1911s for Pew Pew Tactical — evaluating them for all the metrics set above.

Additional testing and content was provided by Pew Pew Tactical Founder/CEO Eric Hung and Video Content Producer Sean Curtis.

Final Thoughts

The 1911 pistol is a beautiful handgun with a rich history that has expanded over 100 years.

There is no sign of sales declining, and it seems that every year at SHOT Show, there is another 1911 maker entering the scene.

If you are late to the game, hopefully, this will help you choose which one to add to your collection.

Are there any we have to put on the list that we missed? What kind of 1911 do you have? Let us know in the comments below! Also, don’t forget to stock up on magazines after checking out our list of the best mags for your 1911.

Latest Updates

August 2024: We removed the Sig Sauer STX, Kimber Warrior, Dan Wesson Vigil, Springfield Vickers Master Class, and Staccato C-series and added the Tisas 1911A1, Dan Wesson PM-45, and Springfield TRP based on additional testing.

409 Leave a Reply

Really a shame Remington is gone - my R-1 is amazingly accurate and rock solid reliable. Not a bad looker either.

You really missed the boat. ED BROWN is the finest custom/high end 1911.

Not only are they perfectly in- house manufactured, they are so well balanced it makes accuracy se easy.

must be nice to have that much money

just put skate board tape there, i do

go to an IPSC match all the open class shooters use 38 super, you are right it is better than the 9mm except it is more expensive, ammo and pistol

i am a 1911 nut and except for my wheel guns all others are 1911s, from a government 45 Springfield to the last one i bought, an EMP 9mm, have STI, custom Caspipara, Colt CCO, love em all, in regards to the EMP i wanted a 4 inch 9, only cause i don't own a 9mm but could not find one at gun show, then along came the EMP with great deal so bought it, was skeptical of its accurate but was amazed how accurate it was and it shoots anything. my thing for the grip is skate board tape, it is on all my pistols even on the front strap, don't care what anyone says about the 1911s they are the best, easy to work on and many, many parts

I am fortunate to own a half dozen colts my father bought several surplus at the end of the war for like $12 each !! new in the box never fired !! others I have accumulated over the years one of all places a yard sale ! i always ask if any firearms . a older lady had one her husband had brought home from vietnam he passed and she had no idea what it was worth ! I cant get into 9MM if its not .45 ACP it aint a 1911 .

I've never owned a 1911 but used them in the Army and National guard (ca 1970's & 80's). I've always wanted one but never bought one. Instead I've bought several 9mm S&W, Canik, etc. Since I don't shoot much any more, I may look at the one budget gun you showed. I bought 9mm when the military switched to them in the 1990s when I was in the AF Reserve. Helpful article for this aging Boomer.

I was just about to add a comment about why no Kimber KDS9C? There is an article in G&A (Aug 2023) about this gun and the author cannot say enough good things. You do not have any H&K either.

No Kimber or Sig Sauer in this group makes it a bogus review

You forgot my choice of caliber, .38 Super Automatic. I bought on back in 1978 brand new for $234 and still have. Have fired thousands of rounds through it mostly my own handloads and it's great. It's a series 70 Mark IV.

I can't understand why more people don't opt for the Super. Hits a lot harder than the 9mm, has more foot pounds than the .45 and a much flatter trajectory and lighter recoil although that has never bothered me and I own a great many handguns ranging from .44mag to NAA .22mag 1" bbl, .45/.410bore derringer and many more. Have a 10mm Glock 20 gen4 and recoil is just not a problem.

But I find it amusing people do all things to try to make the 9mm into a major when they could just get a super. I have been getting 1500+fps with 115HPs and great functioning.

Another I like although I have only owned a few years is a TT33 tokarev. I can't wait to sail a couple over the chronograph as it says 1722fps on the box. That's why I bought, so we'll see.

Nice article by the way, a lot of work went into it. I just wish you would have included some supers. No double stack Colts but 9+1 with almost 600 FT*lbs-1 is not bad.

An interesting oddball you may want to check out is the scaled-down Browning 1911-380.

Why does PPT consistently ignore Kimber in their 1911 comparisons?

Just doesn’t make sense.

You can pickup an entry level Kimber for around $600 and having a 1911 with great fit (accuracy) and reliability

Years of experience and lots of range/downrange time......I like my Kimber (feels good, shoots accurate, and the trigger is outstanding).

Front strap checkering is a deal maker or deal breaker...Shame on S.A. and Colt for not making it a requirement..

Y'all act like not having front slide serrations is a bad thing. Frankly, I can't stand them and don't want them. Not everyone does a stupid press check. I have a friend who was almost shot by a co-worker doing a press check on his duty weapon that had been in a locked locker the entire shift. The dumbass had his finger in the trigger guard.

Just curious, with red dots on pistols being increasingly more popular, why do the MOS 1911's seem to be so rare? I mainly see them on Kimbers. As I roll into my mid-60's, I appreciate the option.

Reliability, quality control, tight military-level specs construction, excellent materials don’t have value?

C’mon… start thinking. Your values are as twisted as your logic.

Les Baer makes a helluva gun, as does Wilson Combat and Dan Wesson (CZ) — I own all three, two of the models listed here — but there are far better 1911s made than the manufacturers and models listed here).

I researched the sig ultra 45 and finally acquired one. took it to the range and loved it. had 2 mags left over and told my wife to try it. she hit all bullseyes at 15 yards and now I don't have my ultra anymore.

Like to see one in 38 super on the list, it’s seems crazy that is has fallen by the wayside, an excellent round for the 1911 since early on.

Much better than the 9mm and easier to shoot than the 10mm, in my opinion of course.

When referring to the Les Baer accuracy guarantee of a 3" group at 50 yds, this is subjective because everyone shoots differently and unless you clamp the pistol in a vise/fixture like Les Baer did at the factory, this guarantee is pointless. Just my 2 cents.

Yes, that group is accomplished by shooting the firearm all secured in a Ransom Rest, while inside, with no wind, regulated temp, etc. And people do shoot differently-based on many factors—experience, distance, hand/eye-coordination, etc. With all that said, I like to see that group size & distance. I remember Les Baer pointing out in the description of his rifles stating his results were based on 10-shot groups, not a 3- or 5-shot like most others.

I think the reason having X”@ YZ yards pointed out on this pistol (& many other firearms) is so you & other potential buyers know what the pistol is “capable” of shooting. It’s up to the shooter to put the rounds in that 3” group. It makes sense to me, even though most of my experience is with rifles. And, I could be totally wrong!

Would love to hear the PPT teams' view on Cabot 1911 (or even Alchemy Custom) pistols and how they stack up against the usual suspects as mentioned here. As you said, there are so many out there...

Mike, if Cabot or Alchemy would send us one, we would definitely love to see how they stack up.

I also trained initially on the Colt 1911 in Navy training. We also used .38 spl, but I preferred the .45. My first 1911, a basic GI version, was from Rock Island. Beautifully fitted slide, no malfunctions. Just a good, no nonsense .45. I recently bought a Ruger SR1911 and love it; even easier to shoot than the original GI version (RI). So, I was a little surprised that the SR1911 did not make the cut for the $500-1000 range, with several versions and price points available. I still shoot them both, and they will eventually go to the next generation of family shooters.

Brian, the Ruger SR911s are excellent guns. This list could be about four times as long since it is truly a buyers market for 1911s right now. The Garrison took the slot that the SR1911 would mainly because of the bluing and the forged frame. Ruger still uses cast frames, although they are the kings of investment casting and are the best in the business at it. I'd like one at some point, but it kills me that only the two-tone one ever goes on sale under $600, haha. I am glad you are enjoying yours!

With a tip of the hat to Col. Jeff Cooper, I believe .45 ACP 1911 is the best pistol evah: there are many pout there, but this one is mine. YMMV, with all due respect to those of us who have brand loyalty for a given manufacturer — but the 1911 is here to stay for a reason.

I trained with the 1911 in the U.S, Air Force 55 years ago, and the first firearm I purchased was a stainless Colt Mk IV Series 70 Government Model the same year I was trained in its use by SAC. Since then, I’ve acquired 4 Nighthawk Custom 1911s; an original Dan Wesson before CZ acquired the company; one made by Les Baer, Springfield Armory, Rock Island, Ed Brown; 1 Kimber; 4 Staccatos, which technically aren’t 1911s… and had two custom 1911s made for me, designed and built for Gunsite Academy. None of this makes me an expert… just picky. I’ll match any of these with Pew Pew’s best at 15 and 25 yds.

My only thoughts on your write up was in regard to the "Cons" for the Colt Delta Elite. For some of us the "missing front serrations" is a plus, as their utility is marginal, but the defacing to the front of the slide, obvious and permanent. The lack of front serrations should be noted as a "Pro" for any gun not defaced by them. If the Garrison had the larger rear serrations of the Colt it would be the perfect budget 1911. A bigger con for the Colt is that it is a Colt. Some of us still remember Colt joining forces with Bill Clinton in sticking to those who love freedom.

Leroy, I feel you on the serrations. Most people see it as a feature; the same goes for Picatinny rails. I really dislike accessory rails on 1911s, but I understand their utility. One of those Les Baer Monolith Stingers with the full length unrailed dust cover and no front serrations is "that" gun for me.

When I first decided to buy a 1911 I was overwhelmed by the choices but did a lot of research and at first had decided on a budget of around 1000.00$. Narrowed my choices to Springfield Ronin 45Acp or a Ruger Sr1911 both very nice pistols that performed well at my local range.....The guy behind the counter asked me to try the Springfield Mil Spec 1911. I fell in love with it's feel-looks-great accuracy and no BS style.# dot sights work well and after over 1000 rounds with no issues of any kind I love it more every time I pick it up! Also own a Magnum Research 1911C 45Acp 4.25" which a a bit more refined than my mil spec costing around 750.00$ compared to 600.00 for mil spec also great shooter. Have shot Tisas ,RIA, Dan Wesson ,Colt. Les Bear....Bottom line nothing feels or shoots like a 1911 and good ones come in all price ranges and even the basic models can be left stck like mine or customized in so many ways! Try as many as you can in your budget range and enjoy! I just wish I could own every one on this list ! PS Did I mention I love my SA Mil Spec?

Mike, Springfield is killing it in the $600-800 price range, in my opinion. My fiancee has a Mil-Spec she bought a couple years back, and it has been nothing but a reliable tack driver. Glad to hear you are having the same experience!

Thanks Wyatt and am glad she is happy with her Mil Spec! And Thank you for the reply and great article keep up the great work! PS Pew Pew Rocks !

Mike, we are happy to hear you are enjoying the content. Thanks for stopping by and commenting!

Good read despite the comments to the contrary. My personal pick, as in I just purchased, is the EAA/Girsan MC1911SC. I wanted a smaller pistol for EDC (note I did not say 'small') and the recent articles on velocity show little significant difference among barrel lengths. Mine is finished in Tungsten and will get a set of rosewood grips with finger grooves. That will be the extent of the modifications.

How about a blog on commander and officer variants.

When I want a smaller EDC I go with the Beretta APX A1 carry but I prefer the 45 over the 9.

I aslo carry the Beretta APX carry really like it even though it;s only 8 rounds. Just curious how do you like the MC1911SC? I have been looking at them. Thanks Mike M.

Jim, I am glad you are enjoying your 1911SC. I have seen those, but there isn't much on the web about those guns, and I have been curious. I would love to do an officer/commander/CCO 1911 article, but it is a little niche. Hopefully we will get one out sometime down the road regardless. Thanks for stopping in!

Colt defender for best ccw

Tim, the old Defenders are nice guns. I am still a bit on the fence about their new guns and waiting for all the QC bugs to shake out after Colt got bought out. I have a newer GI 1911 and while it runs well, the fitment wasn't great on mine. It would be nice if CZ sent some of the Dan Wesson folks over to Colt to iron everything out, haha.

I own a ParaOrdnance 14/45 limited I purchased in 1995...perfection.

I also have a Taurus PT1911 i phrchased used in 2018, which has never given me any problems.

Next 1911 will be a 10mm double stack...

Rick, the Rock Island double-stack 10mm guns are pretty sweet. I've been meaning to get around to grabbing one for some time now.

I have a 45 acp Springfield Range Officer that is very smooth shooting and accurate.

The Range Officer models are solid guns. I have a Range Officer compact in 9mm, and it has been a great shooter.

Wyatt - My grandson's actually shoot the big old 45acp better than my 9mm pistol. The bigger of the two boys loves the 45. I think that when he turns 21 I am going to gift it to him. It doesn't matter because as long as he is at my house he can go out and shoot whatever gun he chooses.

That is amazing turning-21 gift, can't argue with that!

Best?

Laughable…!

Warned-up blog leftovers…

Why was the Staccato C Series eliminated?

John, Staccato has discontinued their single-stack C-series. The only remaining guns in their lineup are 2011s, no single-stack 1911-type guns anymore.

Hi Eric I have a new colt gold cup trophy in 45 acp.this is an incredibly smooth and accurate gun designed for competition. Use high grade match ammo and you will also love this gun.

I have my eye on that one for my birthday coming up in a few weeks. It's in stock at my dealer. I check everyday to make sure they don't run out.

I’m 72 years old, bought a Kimber raptor 11. Impossible to rack Pistol without stoving a bullet.

Sent it back to the factory they changed the recoil spring and made it worse. Now the absolute worse Pistol I’ve ever fired or owned.

My late wife decided to,listen to a gun store clerk who’d previously sold her two “girl guns” — a Walther PPKS and Colt Mustang, both .380s — and has nothing but problems with the Kimber. If you speak Aviation parlance, you know what a “hangar queen” is, and the Kimber went back to the manufacturer so many times I lost count. It eventually was capable of firing ten out of ten rounds without some problem, but I don’t trust it: it’s sat in my safe now for 30+ unused, only because it would be inappropriate to use it for a paperweight.

Very nice article but you left out some good ones including my favorite Ed Brown 1911s.

Nice article but I think you should check out the Ed Brown 1911 pistols. I have or have had quite a few firearms in my life time and the two Ed Browns that I have, rate right up there with the best

Interesting thing:

with the change in may issue to shall issue ccw w permits--one of our local counties says: May not qualify with any 1911 style pistol. Interesting.

I was disappointed that you overlooked the Ruger SR1911. I purchased mine 10 or 11 years ago. Accuracy - one of the most accurate semi-auto pistols I have ever fired... when I do my job, 2" groups at 25 yards are common. Reliability - I have never experienced any sort of malfunction... period. Fit & finish - beautifully finished, operates smooth as silk, and the trigger is perfect. Perhaps my experience is an outlier, but I have not met anyone who has expressed disappointed with their Ruger.

Nighthawk?

Check out the Tisas lineup. Get a model made from 2023 on, and all parts, other than recoil spring plug, are machined! No MIM!

Never heard mention of my EDC a Para Warthog SS! Have seen good and bad reports of them, about 100 rds into the 200 rd break in period hasn't failed one me since. I've had many a 1911 through the years. In USPSA competitions, first used a. 45 Colt Gold Cup in a year it sounded like a bag of beer cans when you shook it. Then went to a custom Colt in 38 Super when it was the thing for major power in open class , comp, red dot etc. Then the double stacks came out... Went to Single stack Class with a Kimber Gold match (it beat the hell out of the Gold cup that I had in accuracy and reliability) still use it today.

At my local gun shop, they had a "Staccato Day" and for the money, I was expecting BETTER.

Failure to feed and jammed up all day long. The rep blamed the magazines. At over $100+ for a magazine, it had better be reliable!

I'll stick with my HK USP or my SIG P226 over a Staccato.

And with a .45 HK USP you can step it up a notch with .45 Super. But, do some research before you try it.

I have a Tisas. M1911A1 I purchased several months ago. Figured it would at least be adequate. Boy was I surprised. The quality of steel, and tolerance put it up among the higher priced STOCK 1911s. Very crisp trigger pull. I put about 30rds through it with no jams, stovepipes or misfeeds. At $350 and up, there's one for your budget. Wish it had been mentioned in the article.

I’d like to know what you think of the CZ 75.

Notwithstanding its weight of all metal construction.

Thank you

I own a 45 utra carry II kimber. Nice gun. Hangs at times on the third round . Maybe breaking in . I noticed I'm getting marks on the bullet when loading the mag. Purchashing different mag. Wilson? But you makes kimbers? I will see. Nice sight. thank you.

Iver Johnson was left out. They make a few different styles & size 1911 45 acp pistols at pretty reasonable prices for example they have a few snake skin patterns that can be applied not to mention some have ported barrels. I recently purchased a Eagle XL 45 acp 8 RD. 6 in. ported barrel with the copperhead snake skin design. Works for me. Check'em out.

No mention of Colt's. Shameful.

My first 1911, is a Tisas from Classic Firearms, which is my EDC. As soon as I got it, took it to the range, and I was not disappointed. If felt good right out of the box. Solid, and beautiful. for the next couple of the months, I swap all internal components to Wilson Combat. Started with the magazines because i got a feeding jam. The only original part is the frame. I love this gun.

Mine is still stock. Love it that way.

I had a bad experience with a 1911 Clone in the early 80s, that I'll admit biased me against the platform. Spanish made, it was a Jam-o magic, that I couldn't get rid of fast enough.

I'm tempted to give it a try, unfortunately, being retired and on a fixed income, it's a wish that most likely

won't take place.

Such is life.

Was it one of those gnarly old Auto Ordnance models from Spain? I understand Kahr has moved production back into the U.S. and they are somewhat better quality now.

Yes Sir, it was. I don't remember if it was Star or Llama that was cranking them out at the time. It looked nice, but I could never make it through a full magazine even with ball ammo without a jam.

Some where, I've still got the reciept I believe. That was many moves ago.

My favorite gun is my Springfield EMP4 CCC. Great size, feel, weight and so darn easy to shoot. I just got the Prodigy 4.25 with a Deltapoint Pro and I'm loving that too!

I also have a Colt authorized Government Model chambered in 22 caliber and made by Walther that I use for my new shooter students. So sweet for a 22!

In the budget category, I would like to see a head-to-head comparison of the "Tisas 1911 A1 US Army" with the "Rock Island Armory 1911." They come in near the same price point. How does the Tisas stack up?

I was just going to post for the best budget 1911 my Tisas at $329 from PSA is a great buy. I love shooting it and it its very accurate. Surprised it wasn’t on the list for best priced 1911.

Thanks to Sean Curtis for granting my wish and doing a detailed review video on the Tisas 1911. I'd still like to see him compare the Tisas with the Rock Island head-to-head.

It was “Gun Tests”, I believe, that did that comparison a few months ago along with a couple of other 1911’s and published the results. The Tisas was a “Best Buy”. You can probably find the article on line. I’ve got an Auto Ordnance that I bought new about 30 years ago. It does NOT like HP’s with big ogives. But, back to the Tisas, reviews have been excellent. I found a GI model at a fairly local LGS and bought it as a birthday present for my son. He LOVES it.

Can you review or consider adding the SAVAGE 1911?

Mine is phenomenal! When I say Savage 1911, most people say, “Why? It’s nothing special.” Glad to know there’s another fan out there that can appreciate quality.

Yes, there are emerging brands that offer very high quality firearms. Girsan is one of them. Moderately priced but with very high quality. I have a Girsan Hi Power (MC P35 OSP) clone that is magnificent; also have the Beretta like pop up barrel .380 (MC 14T) that performs without a hitch.

Y'day was at the range with a buddy who had some very ''expensive'' pistols and rifles (H&K, Glock, Winchester) that just did not perform flawlessly, matter of fact the Winchester jammed every other cycle. My moderately prices firearms trumped those expensive brands. Times have changed.

ANYONE THAT LOVES THE 1911, NEEDS TO CHECK OUT STANDARD MANUFACTURING 1911s...They have the Old School 1911 look and feel...They have very sweet DEEP high polished blueing...They also have awesome case colored/hardened models...The case coloring is done the old fashioned way...You have a choice of both models with engraving too...I have several and they shoot as good as they look...All the gunsmiths are 40 plus years experience from Colt Custom shop...I would put them up against any of the above listed any day...To top it all off they are very reasonably priced...You can Custom order 1911s made to your specs...

You Lost me at your number one pick for a 1911….Rock Island? Really?

The list goes from (roughly) least to most expensive.

Hey Ed, thanks for commenting. This list is in no particular order other than sorted by price. Thanks for reading!

My favorite 1911s are from Sig Sauer. I come from copville, so a heavier trigger is a must. They start off sith all you need, and go up to wild show off designs. My daily carry is a 5in. blue, w Hoge Pau Ferro grips. And, of course, in 45 ACP.

So, no shooting nor any other form of evaluation for most of the guns, just a junior-grade listicle. Thanks for the mini-catalog.

I carry daily a Springfield Champion (1911 45). And have for some 35+ years. Has Never failed to fire, outside of when first breaking in has never stovepiped! So far been a very nice and Dependable firearm! Also have a Norinco 1911 (45)! Better fit and better shooter than a friends Mod 70 COLT! Finish might not be near as nice, but don’t have any Wall Hangers! Just Shooters, and the Norinco is a shooter! And at the time of buying only some $75.00! Beat that Colt!

Are Norinco being imported into the US? $75 cost?

I purchased mine used about 3 years ago for $500. It is one of may favorites among my other 25 1911s( Dan Wesson, colt custom, nighthawks, Wilson,Baer,brown, republic forge, Springer custom, gun crafters).

They were back in the Day. Bill (I did not cum in her mouth) was President and was banning about everything!

Check out Standard Manufacturing 1911’s..

Rock Island, known for making junk, is your top budget pistol? Kimber, the possibly the most over-priced and over-rated pistol is one of your recommendations? Wow, your credibility just tanked! It’s obvious that you are no longer objective. What a shame.

Rock Island is one of your top picks, even though they have a reputation for building junk? And you recommend a Kimber, one of the most over-priced and over-rated pistols on the market? Wow, your credibility just tanked!

I’m rather curious as to why Taurus was left off of the list… for that matter, what about Browning? I have a Taurus Homeland Defender 1911 45acp & I love it! I also have 2 (yes: TWo! Browning 1911 380’s: one is a carry model, the other a ‘match’ model… I never leave home without my trusty Browning 1911 380…

Curious why none of the Colts (except the Delta Elite 10mm) made the list?

I just purchased the 1911 .45 ACP Government Series 70 Competition in SS. ($998)

I absolutely LOVE it.

Big fan of the Novak front fiber optic, and rear adjustable sights. The blue G10 grips are a nice touch.

2000+ rounds later, I've had zero issues and its very accurate.

The best shooting .45 is a .38 Super. That said, I wish I'd never bought/shot a .45 and had stepped right into the 10mm 1911's from the get-go. If I'da written the article I would have probably tried to squeeze the Desert Eagle 1911's in there somewhere. Great triggers out of the box, durable, well appointed for the price range and good looking. In spite of the full length guide rods, they're good guns, and good shooters. I've never shot any high end 1911's so I can't speak to those. The Sigs and Springfields are pretty good, IMO. I've owned a number of Colt's but I don't think they're really much of a value any more, with the quality and features you can get from a bunch of other makers. For daily carry I am partial to the old-school government models with the old style hammers, but most of them are lacking in front strap stippling, so I'll usually slap a Hogue monogrip with the finger grooves and I'm all set. No matter which way you go, 1911's are a ton of fun to shoot.

Bought way back in the 1990’s. Springfield Champion! With the 4” barrel, and full size frame. Love the Gun and is the Everyday carry for years.

Also have a Norinco 1911. No rattle and a very nice shooter. Bought before Bill (I did not have Sex) Clinton, shut everything Down! Somewhere around $80.00 USD! Try that now!

I LOVE my colt 1911 made in March of 1913 still have original magazine it was shipped to U.S. Army had brown finish ( not much left) but I shoot it every now and then love feel of it in my hand kicks like a mule but what ever you ain't getting up. Was told by the seller it was issued to his grand dad in ww1 his dad carried it in ww2 he carried in Korea just love that work of art

I want to add to the comments regarding the Tisas A1 from SDS imports. Think about this: a GI 1911 that looks good, hammer forged barrel, slide (and frame?) and shoots great! I mean, like so good not even cleaned out of the box eating everything I ran through it including hollow points! I have shot very nice Kimbers that have not functioned this well. This NOT as fine a piece as a Kimber, but it runs as well as any that I have used (two), is built better that the Rock Island and is now selling for $330. Really. $330. Buy two!

I have a Springfield 1911 a-1 I bought at Tacoma guns when I was in the army and I have a tissas 1911 tanker I love them both but I gotta say the tissas is a SWEET SHOOTER . And even better I was out the door for like 334 dollars

I agree I have one and love it

AMT .380 Backup. A true blast from the past. That made my day. I have a AMT 380 backup and a Hardballer. Both shoot well.

Another 1911 that is worth mentioning is the Springfield Ronin. It is a smooth shooter and looks nice too.

The Ronins are great pistols. We probably could fill an entire list with just Springfield products, so it is always tough to pick just a few!

i would definitely have to agree with you.

I also recently got a Wilson Combat, mine being the CQB Elite. Waited over a year for it. I took out the shok-buff and swapped for a 16lb spring and I've got about 1200 rounds through it after a month without issue. Wilson tends to overspring their .45 and 10mm's.

I have a lot of 1911's and have built 6. The CQB Elite is truly incredible(damn well better be for the money) and is definitely the pinnacle of 1911's....but a Springfield Mil-Spec, Garrison, Operator will serve you well and are reliable as hell. I point most people to Springfield. That Larry Vickers Collab 1911 looks like an absolute steal

I've carried a Smith & Wesson 5" 1911 for over 25 years. I noticed that you didn't comment on S&W at all? This gun has never let me down and I've never had any kind of malfunction with it. Even when caried concealed it is easily the most comfortable of all my other guns. Why, in your estimation did it not make the list?

S&W is No. 4 in the article's top picks.

Fired gov't 1911 in the Marines, have or have owned Para Ordnance, Kimber and Ed Brown. Love the 1911 and the 45 ACP BUT for carry I want total reliability and accuracy with high capacity, so I carry a Glock in 357 Sig.

Hmmm. I have carried a 1911 in combat. While it was most likely a WWII vintage firearm, it did save my butt more than once. (Viet Nam 68-70). From then until now I have carried and made a living with firearms of one sort or another. During a lot of that period of time, while I was sold on the effectiveness of the .45 acp round and rather hard wired to the 1911, I am also left handed. The ambi safeties of the day left something to be desired, so I carried in various non-recommended manners. Never had a problem. My potential problem was solved when I was introduced to the Sig P220. Never went back. Now I still love the 1911 - nothing feels quite like it in the hand and shoots in the same manner. Parts have gotten better as have my gunsmithing skills. I do own several 1911's - a 1930 Commercial, a Remington Rand WWII survivor, a Colt officers model I put am ambi safety on and a pristene model 70 (actually belongs to my wife) but I did not have a 1911 for just knocking around and taking to the range or whatever. The one's I have, have just become too valuable! I wanted something to just have as a shooter. Enter the Tisas. A faithful copy of the 1911A1. Good fit and decent finish. Also at a price of under $400, it was hard to pass up! I have not taken it out for a break in session yet, but from the looks of it, it will fill the bill nicely. I see an ambi safety and perhaps better sights in the future of the Tisas. Besides, I need to have something that utilizes the hundred or so 1911 mags I have amassed over the years that I will use! (BTW - I used that 220 Sig - the first one with a heel mag release for about 10 years - then bought one with an "American" mag release and carried it for 30 years - still have it and it is still an amazing .45, but it has been retired to a "standby" status. The other .45's are for enjoyment. Until needs change.)

I too could not pass up the Tisa. Less that $400 and tolerances equal or greater than my 70 Series Colt. It's the 1911A1 that needs better sights but at 10 yards I am happy owner. Only fired 40 rounds so far but a good gun. Only complaint is that the springs feel quite stronger

than Colt's. Maybe they will break in.

I cannot belive Tisas is not on here, while you have four confirmed pieces if trash!

I cannot believe Dan Wesson didn't make your list....

Me too. Bought a Classic Bobtail (Very few Commander size currently allowed in Commiefornia) and absolutely love it.

Yeah, CZ makes a good 1911.

Yes, Dan Wesson is probably the best production 1911 made in terms of fit, finish, parts quality, etc. I own and/or have owned Kimbers, Colts, Springfield Armory, and Dan Wesson's, and the Dan Wesson's are easily the best in my collection.

Far from an expert. Singer Sewing machine also owned Graflex Cameras.

In terms of 45, The Glock 21 Gen 4 is $551. Standardized parts. Being able to license a design and have them work is simply amazing.

I've had the Les Bauer premier 2 for 20 years. Never a ftf. Very accurate. Rail to frame fit still rock solid tight Have tried lots of 1911's and wouldn't trade this for any of them.

You forgot Les Baer his 1911s out of the box I think best quality for the buck for a manufacturer's firearm. He builds as close to a hand built gun better then any other manufacturer out there.

Impressive ,to be sure! One of my students brought one to a class - He asked if I wanted to shoot it. Silly question, of course I would shoot his gun! Premium quality firearm, to be certain!

Countless articles written on this weapon have Rock Island as their top 3 to avoid (along with Kimber). Yet this guy has them listed as his number one? Lol

What, no love for the Auto Ordnance 1911 in .45 ACP? I’ve seen it referred to as the closest in design and manufacture to the original 1911’s.

I’m sorry but Remington Rand was a typewriter company. Remington Arms Company was not contracted by Colt to produce WWII 1911s.

I have a Remington Rand 1943 1911.

They’re neat! But in no way related to Remington Arms.

I just got a Kimber Custom LW in 9mm ….. I used to think Springfield’s 1911 in 9mm was the go to for that particular platform. Until now. I love the weight, only 31 oz for a full size. Couple that with a 5” ramped match grade barrel and one of the smoothest mag wells I’ve yet seen on a 1911 and you are set up with a perfect out of the box home defense pistol. I’ve run about 400 rounds through it now without a single failure. Accuracy is top notch. Going to move it to bedside gun status once I hit 1000 rounds, loaded with Federal HST probably.

Plus, the price (new) was $720 if I paid cash. And it is in what Kimber calls the Night Patrol colors, which are gorgeous.

Love my stainless Kimber ProCarry in 9mm!!!

I liked those so much I bought two of them along with some ten round Wilson Combat mags. Also gave an engraved pair to my former boss and his new wife in presentation box. Needless to say they were thrilled. I have had zero issues with these two and with my Kimber 45 Aegis. I did change all the grips on them to G10's and mine are the stainless ones. Got a shoulder rig and an OWB holster for them and two 2 round mag holders. When it gets cooler out I am going to try them out around town carefully hidden. Something about a 1911, I can get a better site pic with them. Old eyes.

Well I have a colt 1911 army issue built in 1913. Had gentleman from colt inspect it according to him all internals are the original. Guy I bought it from said his grandfather and father carried it in ww1 / ww2 he carried it in Korea. Still shoot it runs great can't beat a 1911 for reliability

In reality, the "best" 1911 in the world is the one you can afford, that shoots well and makes you happy. A plus is when your buddies look at it with envy.

I have the RIA at the top of the list. Far superior to the Ruger 1911 out of the box. I have a Nighthawk Custom. But I carry the RIA. I have a couple Kimbers. One made in Clackamas Oregon bitd. And one made wherever they are now. Both cost 3x the RIA and are not even close in quality. The Oregon made Kimber is a touch better than the later model as far as fit and finish is concerned. The RIA has a superior trigger to the Kimbers. It's not even a contest. The Nighthawk is in a class by itself in every regard. Believe it or not the trigger on the RIA is very nearly as good as the Nighthawk. For a <$600 1911 that's saying something! Maybe I got lucky?

I think you got lucky. I have an RIA 1911 and find it to be basically the same as the M1911A1’s I shot in the army. A good shooter, but not refined for accuracy and performance.

Hard to believe that you gave Nighthawk Custom just an "honorable mention". These guys make THE finest 1911 period. Yes, they are expensive but the differences are real and worth every penny.

On another note, I know several very high end 1911 custom builders who tell me Dan Wesson is the best production 1911 made, yet no mention.

Wilson combat, nighthawk, Ed brown, les Baer, Sti… in this order from a man with 250k in 1911s

Did Vickers use that 1911 or a Glock in Waco?

No Dan Wesson?

I got rid of my Ruger 1911 quickly after buying it at Cabela's a few years ago. It literally was falling apart as I shot it. The bushing split apart. The trigger was glitchy. The grip screws and trunions were junky, even when "glued in." The trigger was too long, but Ruger refused to put an original shorter one that fit my hand. I had a trigger job done to fix the factory quality, but Ruger said if I retiurned it to them for service on any of the other flaws, they would charge me to restore the original factory junk trigger, thus restoring it to factory spec's. My custom trigger was 4.5 pounds. Hard to believe the hassel I got. They ought to sick to their rifles.

One more thing, if I may. If I were to choose a 1911-ish “precious” , right here - right now, my first firearm and kick off my training and real-world induction, I’d chose a piece that combines features from both “worlds”: the Springfield EPM / 9mm. Cheers!

Greetings.

I come from a country that (idiotically) prohibits citizens from owning firearms.

However, gleaning international content (with regards to ALL aspects of firearm topics, being assembly / disassembly, safety, cleaning, shooting and manufacturing), keeps me sharp in mind, provides insight and is fun. In the hope that should the local status change (possible but not probable) or should any sort of widespread crisis occur, yours-truly would be, at the very least, a tad “literate”.

Anyways… I came across this article by chance and to me it is jaw dropping due to its simplicity, snappiness and comprehension.

Many, many thanks.

Cheers.

George from Greece.

I have a S&W model 457 .45 with hogue grips. I love it and it never leaves my reach.

GREAT EDC!

you left out Les Baer.... almost the same quality as Wilson Combat

I think a major option was missed with Dan Wesson. I would rather have a DW over many of yhe mid $1000 options listed here.

just a suggestion, check out the Magnum Research 1911C by Bull armories in Israel.

I'm fairly new to them,always wanted a simple GI or clone,nothing fancy or expensive,shot a couple Rock Island 1911's,handled several in shops along with ATI,Iver Johnson,and Springfield's, Kimbers,Colts,Dan Wesson's and a couple Les Baer just because they are always in the local shops and I could and wanted to see each end of the spectrum as far as quality.Rocks are very nice budget friendly 1911's,but IMO Tisas is the better deal.I found their 1911A1 Service in .45acp,checked it out,looked and felt great,talked to friends with experience and bought it.Glad I did.I run no less than 500 of the cheapest steel case I can find thru any pistol before I even consider for carry.500 Tulamo,Wolf,and Barnhaul steel case,while gun left dirty then 50 S&B JHP and 10 Critical Duty,with zero failures.In the stock 8 round MecGar magazine.Loved it enough to change some things,different trigger,Polished the bow slots and all contact points for the sear,spring and disc,reset pretravel and post travel,and break weight.Replaced hammer spring,firing pin spring and firing pin block with Wilson Combat parts and replaced the grips with wood Classic Double D grips from Altamont.

As of today 1730 rounds of different make thru it with zero failures.Shes more accurate than I am,looks and feels great.Machine work fit and finish is as good as any in it's category,better than some.With Abit of work she reliably shoots as fast as I can pull the trigger.With about 1/16" of total trigger travel now,I can pull that trigger pretty fast.

Already had an RIA plus cash offered for it.Have their 4.25" Carry waiting for me to pick up.

My 1911 is a Dan Wesson. It was my first hand gun. Went 1911 because a buddy carried one and I like the look. His was a Rock Island, but when I got mine, they didn't have them in stock...but they had a Springfield and a Dan Wesson. I didn't like how the Springfield felt when holding it. Ya, that was the deciding factor!

The Springfield Armory 1911 Cabela's links take to to an XD model on Cabela's website.

The 1911 is my all time favourite handgun, I have owned most of the major brands from basic to high end, and in all populars calibers from .22 to 10mm. From Norinco to Nighthawk and Wilson. IMHO one of the best values in a 1911, is a Colt Mk IV Series 70 Gold Cup from the early 70's. Just an iconic pistol and you can pick them up at reasonable prices. The best shooting 1911 I have had is a Les Baer Premier ll, amazing smooth tight action and it shoots better than I do! (A close second is an Ed Brown Kobra carry). I have not tried a Staccato yet, it's on my list!

1 question . Why no DW in your list ?

A bunch of makers missed. I have a Citadel in 9mm (they're the same folks as Rock Island) that isn't beautiful, but sure is nice and shoots nicely, so far. And it was less than your de facto threshold of $500 (bought during the early part of the Covid run on guns). As a matter of fact, even with current hi-demand prices, I can find 1911s under $500 from Taurus and such.

Have you ever looked at Fusion Firearms? They are absolutely the best 1911 in the 700-900 range.

I have owned examples of most of the productions 1911. IMO Colts are the worst of the bunch. One was a trophy gold cup and the other a government level. My smith said the ASs were better made. I almost had to give them away in trade just to get rid of them. I have moved on to WC, Nighthawks, Brown, DanWesson, etc. The Colt I have now is a Colt Hawk which is a Nighthawk customer Colt 70. Hopefully CZ can produce a Colt worthy of its history.

Hi Eric, I am super new to buying guns but read your .45 best rated in your opinion and would you happen to know how I can obtain a SA 1911 Vickers Tactical Masters?

You were kind of tough on my Rock Eric.... I've had it for many years and it has been through the fire while never failing me. Just saying! Love the article

I have several 1911s, my Gold Cup Trophy was the worst of the lot fit and finish wise. Grip safety, and magwell were loose, thumb safety poorly fitted, frame had numerous scratches. I don't expect to have these things to fix on a new in the box firearm.......But that's just me.

I have a Colt Gold Cup National Match 45ACP, a Gold Cup Trophy in 45ACP and a Gold Cup trophy in 9mm. I had zero of your issues with any of them. They are much more accurate than I could ever shoot particularly the later 2016 Trophy models I have. I also have an STI Rangemaster in 9mm and I'm hard pressed to gauge an accuracy difference between the STI and the Colt 9mm Trophy. I cast my own bullets and Hi Tek coat them with excellent results once I found loads that suited each gun with me shooting them.

The worst gun for jamming was my Colt Light Weight Commander. Didn't matter what ammo I ran through it just gammed all the time. Guns smith looked at it, said "This is a new gum should not be doing this" but it was.

SIG Ultra Compact. Under $900 with a ramped bull barrel. I put 500 rounds through it out of the box before cleaning and lube. No malfunction and very accurate. And it’s good looking too. Best 1911 I’ve ever touched.

Dan Wesson deserves a mention here

I own a Soecialist and Guardian and couldnt agree more

I have 2 DanWesson .45’s, and three Dan Wesson 10 mm.’s I trust my life with those guns.

I’ve had my Les Baer Monolith for over 20 years. Shot thousands of rounds including everything from reloads to expensive defense ammo and never has a single failure. The trigger is absolutely flawless. It’s a big heavy gun, probably too big for everyday carry for most people, but what a work of art!

Staccato-P (comes with 2-17rd -flush and 1-20rd) mags and C2 (Carry model) comes with 3-16rd flush mags. Double stack 1911 duty pistols. Best on the market.

I've got to second what LTC C said earlier. I was shocked to see that your list of the "Best 1911's for the Money" didn't include any Dan Wessons! You can't touch the quality of a DW without spending $500-$1000 more.

When I went shopping for a 'higher-end' 1911, I compared the DW Valor to Wilson Combat, Nighthawk, Ed Brown, STI, Les Baer, and a couple others. The Valor compared favorably to any of them, at a considerably lower price. Ended up with the Valor, and have since acquired DW's in CCO-size (Valkyrie) and Officer's-size (ECO). The ECO is an absolute gem! I've got 1911's from Colt, Sig, and Les Baer, but think the DW's were the best bang-for-the-buck.

I know of at least a couple guys who, after shooting a Valor, went & sold their 1911's (a Kimber and a Springfield) to get a DW!

No list of best-value 1911's at moderate prices is complete without a Dan Wesson or three on it!

Agreed. We own several as well as from nighthawk custom and ed brown. Personally I think they have done a great job with the new v-bob and would love to find a guardian either in 9mm or 45.

Just a comment about price not always indicating quality. Although my husband has been happy with his ed browns I have not had that experience. A recent purchase with 2 quality control issues so far. I am a bit turned off by a company that doesn’t answer their phones and wants to be paid to evaluate the issue. My husband had a minor issue with a new nighthawk custom 1911 and the way was this was handled by the company was drastically different. We have never had an issue with the DW 1911s and I do not recall hearing or reading of any horror stories about customer service.

Nice list of options. Kinda hilarious that you'd question the viability of a bare bones RIA as a duty weapon. Compared to the rattletrap stovepiping, shot-out Colts that I was issued in the Navy in the late 80s, my $399 (on sale, in 2008) RIA is a dream. A couple thousand rounds in and nary a hiccup. Nice slide fit. Better trigger than any striker fired plastic fantastic. Plenty accurate and hits point of aim with basic fixed sites. Shouldda bought 10 of em, as they seem to be unobtainium now. You can pay a crap-ton more, but unless you're a competitor or a fashionista, the rewards are questionable.

I absolutely love my RIA .......

Great list!

If I may add, Dan Wesson Valor gives you Wilson Combat, Les Baer, and Ed Brown level fit and quality at a better price. I've owned them all at one time or another, and it's hard to justify $3,000, when $1700 +/- will get you the same.

If you are willing to accept MIM parts, then Kimber's current crop of government models in. 45 ACP are hard to beat for around $800 +/-. I've had feeding problems with other calibers.

Sadly, every Colt I've handled in the last five years simply did not have the same quality slide to frame, grip safety and barrel fit. I just can't justify buying a current Colt, unless I hand selected it in person...

For that sub 500 price range, I picked up a RIA in .38 Super. Fun to shoot. Low recoil and fits perfectly with my collection of 1911's

Like to find a 38 super by Ria..and ammo

You will need to reload for 38 super. That will be a good thing.

I have a Dan Wesson 10mm that is absolutely a dream to shoot, i have been pleased with the fit and finish of it, the price point is moderate for the quality that you receive, can't be beat ...

Loved the review Ive allways love the 45 1 disabled 100% veteran and chose the 45 over the 9mmwith my budget its hardto find one that wont break the bank,maybe the rock island thnx

The RIA 1911s are sturdy and eat anything you put in them. Maybe 4-5 FTE in ~2000rds with my Ultra FS and those duds were with the alum cases. No issues with reloads but it does tend to ding to cases. I'm not a competition guy of any sort but for the hobbyist I would definitely recommend the RIAs.

Thanks for review - very useful. Putting the dollars aside - would you prefer the Wilson Combat CQB Tactical or the Vickers Tactical Master Class (you mentioned lots of Wilson parts), with accuracy and quality as criteria? Thanks.

I am a Marine Officer from Vietnam flew the old UH 34, lost it on Hwy One north of Danang - -also lost my 1911A1. I realize I will never see that particular weapon again, but was rather good with it in my hand. I am now 76 yrs old and looking for something comparable -Can you help me. Thank you for your time

Any 1911A1 made by a solid brand would fit perfectly! I would recommend Rock Island if you're working with a small budget, Dan Wesson if you have some money to throw into it.

Would suggest a Norinco. Made in China and faithful copies of 1911A1. Not pretty and a little rough but tough. It’s my dirt gun; all of the pretty Browns and Nighthawks stay home. Probably in the $500 range if you can find one.

Have a Rock Island 1911 GI in 9MM that I picked up used for a couple hundred. It must have been babied because it looked like it had hardly been shot. I love it at the range. Shoots flawlessly and on the point every time. And it looks and feels so retro.

Hi, have you guys tried the Rock Island TAC ULTRA FS HC? It's a 1911 in 45 cal that is a double stack! I've always been a 1911 fan (prior service) so when I wanted to get back into shooting after a very long lay off, I went looking for a 1911. The biggest drag has always been the seven round capablity. And since this isn't a carry weapon, the RI TAC ULTRA FS HC is perfect!