Setup

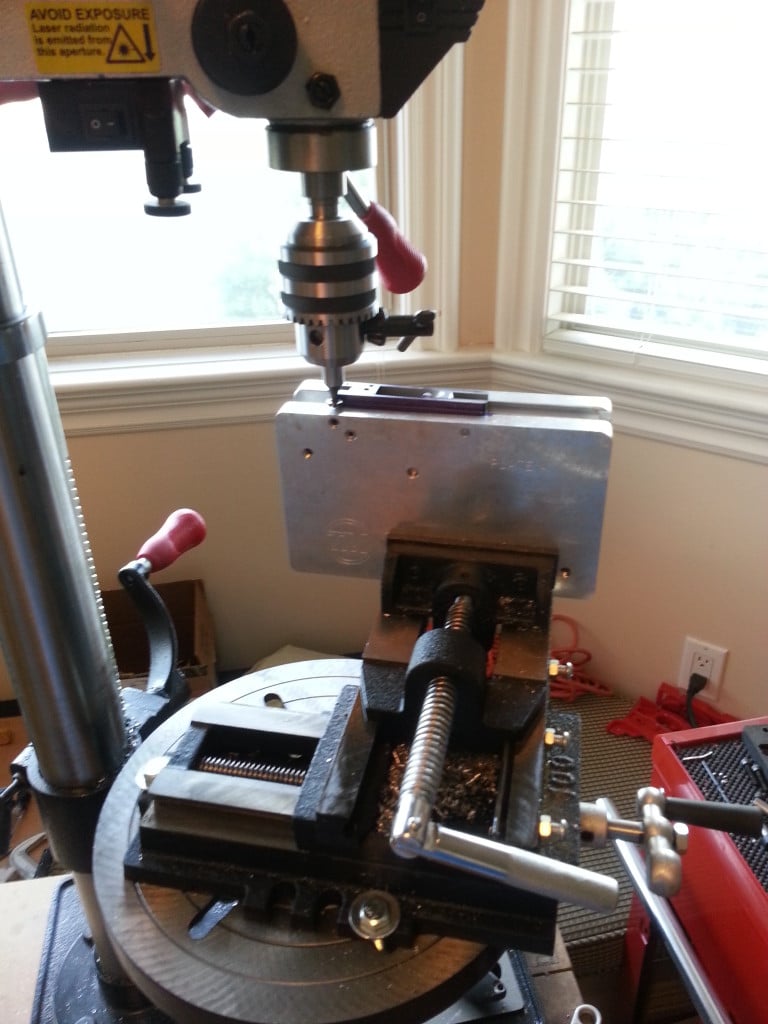

You’ll also need the bits, drill press, sliding vise, calipers, & Dykem I mentioned in Part 2. Tighten everything down and make sure you can smoothly move the main axis of the sliding vise.

Measurements

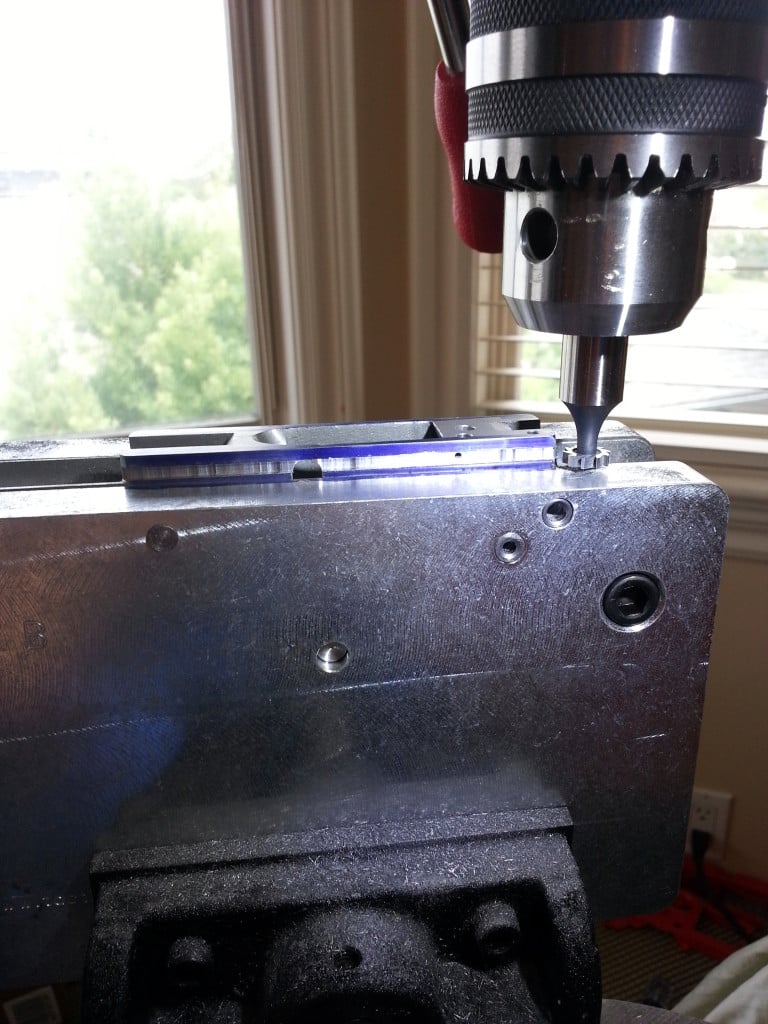

Double check your resources and measure your slide with a good caliper. For me, I am going to cut down .105″ from the top, and go .05″ deep. The 3/32″ keyseat cutter comes out to be .09375″ while the slide’s thickness is .12″, so there will be some filing. The square file in the file set tapers from around .09″ to .011″ so it should be good to go.Dykem & Marking

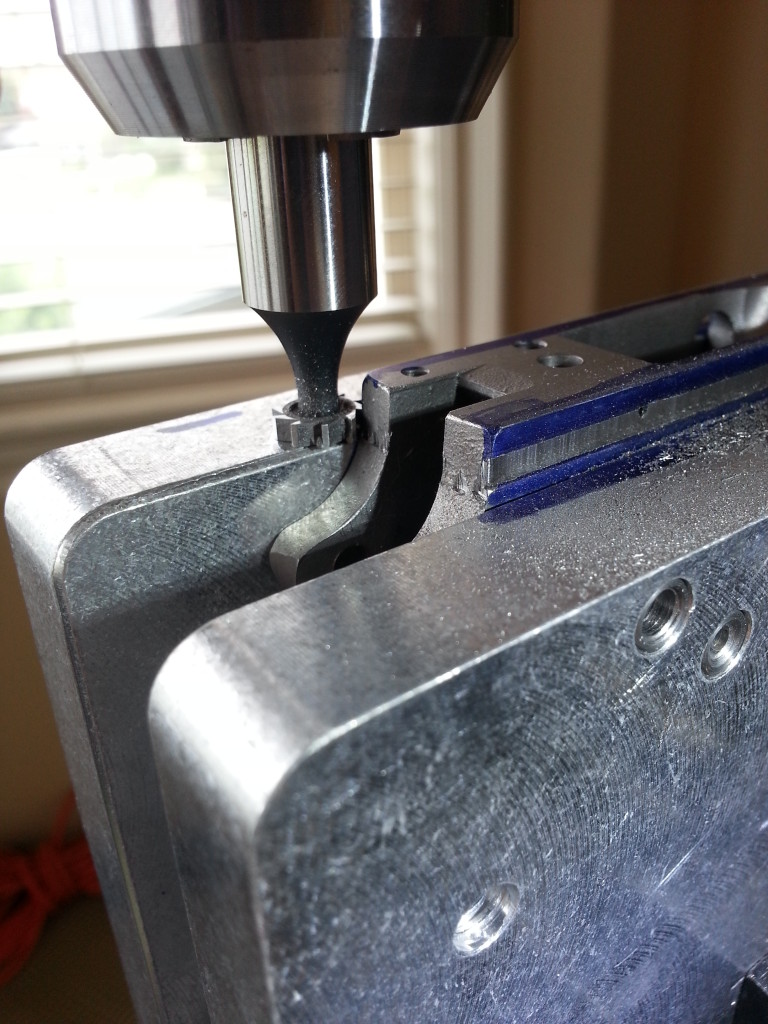

Before you put the 80% into the jig, paint some Dykem on it. I got excited and put it into the jig first before painting so you’ll see blue all over the jig in the pictures. I would put it thicker next time too. Do it in some well-ventilated place and let it dry. Measure off .105″ on your caliper and lock it. I put the edge of the caliper on the top of the paperweight and let the sharp edge cut into the Dykem. Perfect!

Vise

Put the jig with the 80% into your vise. Make sure you’ll have enough space to move everything around. Last thing you want to do is reset halfway through when your jig hits the drill press. I’m definitely guilty…Get into Position

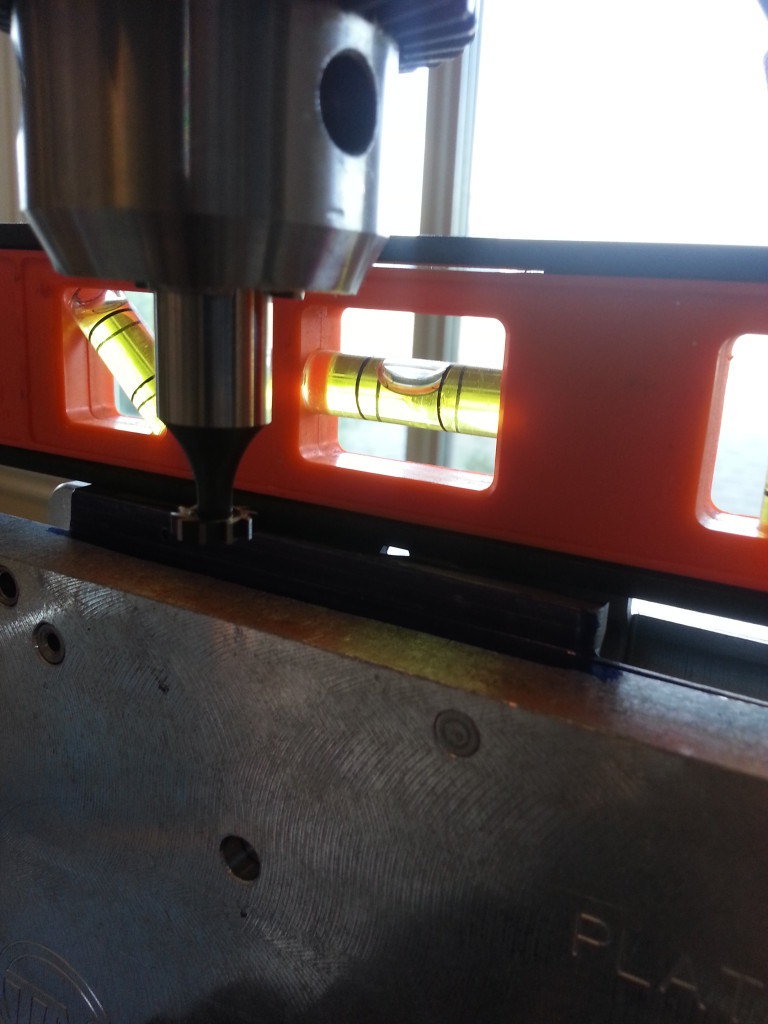

The TM jig fits well but you cannot expect it to hold the 80% perfectly level. Use your level and if needed, move the jig around.

Cutting

Measure twice…or ten times, then get ready to cut. I went for something around .04″ deep for the first cut. Make sure you hold the jig steady and not yank it…you can see my deeper cut about half an inch from the right side. Then just go nice and slow while holding the line you cut into the Dykem with the caliper.

Next Lesson

Part 1: Intro (Finding the 80%)

Part 5: Cutting the Slide Rail

8 Leave a Reply

Hello,

I was going over your article about building an 80% M1911 and, in part 4, I think, you note certain measurements as below. It would seem you mean that 0.09375 < 0.12, not 0.012 as stated. I am wrong about that?

Thanks Bruce

The 3/32″ keyseat cutter comes out to be .09375″ while the slide’s thickness is .012″, so there will be some filing.

Hi Bruce, I believe you are correct. Thanks for catching the mistake!

What did you use to clamp the vise to the drill press?

I used a couple bolts/nuts/washers I had lying around and aligned the vise to the base of the drill press the best I could.

what rpm/speed did you set your press at? also how long to just cut the rails on the press(not file too)? did your bit stay sharp?

thanks, thats a clean build

Thanks! I set my drill press to the fastest rpm. The actual cutting was very quick, probably a few minutes each side. I spent a lot longer just double-checking the positioning of everything. I also found no problem with the bit staying sharp for a couple passes on each side.

Hi Eric,

Where did you get specs for cutting the rails?

Thank you

I got them from my Kuhnhausen book, but there's this link (choose 1911-A1 blueprints).

But the best is to start there and measure your actual slide since that is what has to fit onto the receiver.