A good percentage of shooters reload and have done so for decades. Why?

It varies from reloader to reloader – some do it for competition, others do it because they burn through so much ammo at the range it’s just cheaper to reload that spent brass.

For me, I’ve reloaded for years. I’ve used everything from a 45-year-old RCBS Jr. single-stage press to a 40-year-old Lee Turret press. But…I have always wanted a Dillon Precision progressive press.

The amount of ammo a progressive press can produce is amazing. Once going, a loaded cartridge drops into the collection bin with each handle pull.

Dillon Precision recently sent me their XL750 Progressive Press, so today, we will talk about it! I will run through the pros, cons, specs, and features, as well as how it actually does when it comes to reloading.

Keep reading!

Table of Contents

Loading…

Dillon Precision XL750 Pros & Cons

Pros

- Quality build

- Reliable performance

- Lifetime warranty

- Good aftermarket support

Cons

- Difficult to set up

- Expensive

- Not for beginners

The Bottom Line

If you want to up your reloading game and become truly productive, the DP XL750 press is just the ticket. Although not cheap, it’s built very well and has many accessories available.

Dillon Precision XL750 Features

- 5-station shell plate and tool head

- Automated powder and primer dispensing

- Automatic case feeder optional, but highly recommended

- Low-primer-count alarm included, and powder check alarm optional

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Background

For a few decades, Dillon Precision has been the go-to company for reloading equipment. Competitive shooters, gun clubs, and serious hobbyists have all turned to the big blue machines to reload.

The company has a reputation for building quality presses that withstand the test of time and use.

Dillon Precision Founder Mike Dillon had a saying that he “didn’t want anybody mad at him” because he wouldn’t stand behind his products. So, he ensured that his company’s products were top quality.

Who Is It For?

This press is for serious reloaders who want to quickly make a pile of ammo and those with a few extra dollars to spend.

This is not a press I would recommend for beginning reloaders, but for those with reloading experience who want to up our game, this is the press to use.

How It Works

The XL750 uses an electric case feeder that holds plenty of cases. I used 9mm for this review, but I still chose to throw a few in at a time. I had a few issues with the rotating plate jamming and sticking, so pacing proved important.

I did eventually get it figured out, and it works as intended now.

Using a Hornady die set; I began working on resizing and decapping (pushing the spent primer out.) Since I was working with a pistol caliber, I expanded the case mouth to accept the bullet. You don’t want to do that with a bottled-necked rifle caliber, though,

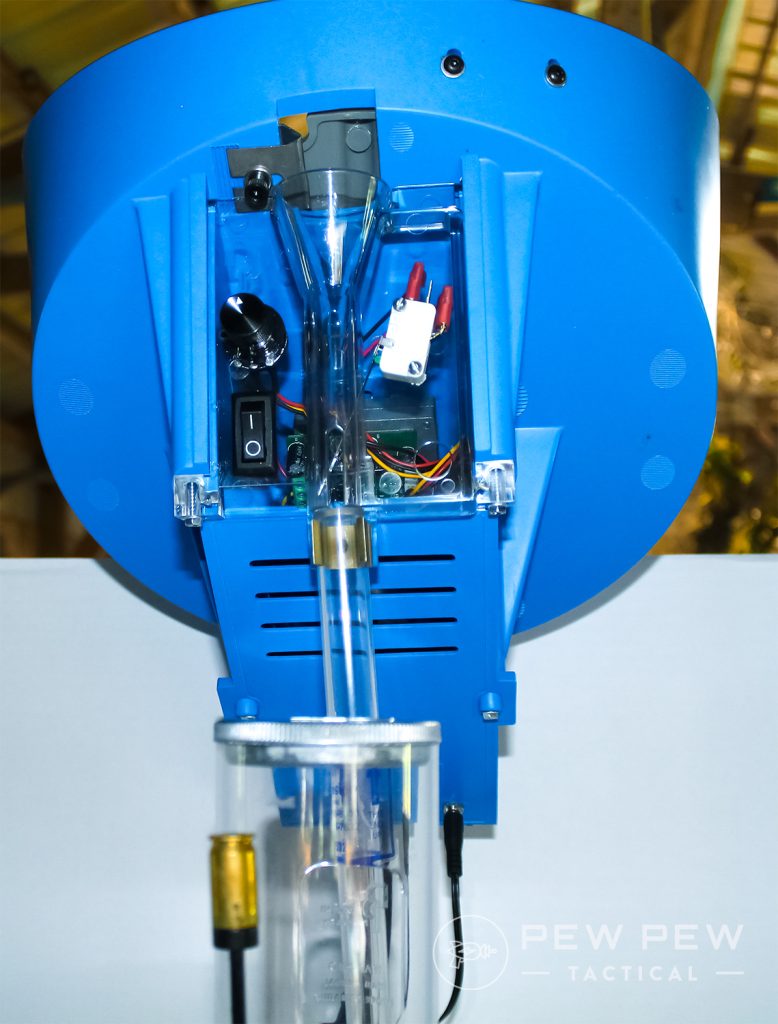

Next, it was on to dispensing the powder. This is done on the XL750 by running the case up into the belling/powder die. After it bells the case mouth, it dispenses a preset powder charge.

From there, I moved into seating the bullet and then finished it by crimping it. Out comes a completed cartridge!

Revolver cartridges will use a roll crimp, while semi-autos are taper-crimped. Admittedly, I had some problems at this stage. Either the crimp was not enough, as you could press the bullet into the case when you pushed it against your bench, or it overdid it and crunched it down, resizing the bullet.

After some trial and error, I found the happy medium.

What Sets it Apart?

Dillon Precision has a reputation for top-quality products…generally considered the top of the heap for progressive presses.

In fact, they’re one of the very few to approach press designs from the progressive level, not at the single stage.

Yes, the cost is high. My current setup is around $1,500, but with that, you get that nice lifetime guarantee, good customer service, and a lot of savings on future ammo.

By the Numbers

Reliability: 4/5

If you set it up properly and pay attention, this system is very reliable, but we knocked it a point for difficult setup, which led to some issues initially.

Ergonomics: 5/5

You can get a roller-type handle to replace the ball handle that comes in the kit, and you can either use the Smart Mount or not to adjust the height of the press. The optional bullet tray is a great $64 addition, as well.

Customization: 5/5

There is an active after-market out there for DP presses, so you will have no issues customizing this the way you want.

Value: 4.5/5

You will undoubtedly repay yourself in loaded ammo for your investment, which represents great value to me. That said, the PPT editors would like to note that not everyone can shell out for this model.

Overall: 4.5/5

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Some Tips & Tricks

As I mentioned, setup can be tricky, so here’s how to get the most success out of our press.

First, pick a well-lit area to set up. You DO NOT want to be mucking about with primers and powder in a dimly-lit space… trust me.

Remember that each handle pull does four operations. This is crucial. I come from almost five decades of experience with single-stage and turret presses. A turret press requires four handle pulls to make one loaded round.

This press does all four operations with each handle pull. You need to check each case for the proper powder charge and then for the right bullet and primer seating depth as it exits the press.

Pay attention, and don’t get distracted!

Use full-handle strokes. Do not short-stroke the handle – move it to its stops, up and down. Otherwise, you won’t kick the old primer out and fully seat the new one. Bad news.

Also, spring for some extras like spare primer pick-up tubes and the bullet tray. The extra pick-up tubes will speed up the process while the bullet tray places bullets under your hand, ready to feed. This definitely speeds up the process.

Add a .45 ACP case on the end of the primer follower rod. It adds a bit more weight and makes the rod easier to grab. I can’t take credit for that – I saw it on the Squatch Reloading channel.

Finally, stick the extraction spring on the shell plate bolt. It holds the bolt in place and keeps it from tightening down, locking the shell plate. Don’t omit it when you are adjusting things.

Ask me how I know…

Final Verdict

As a reloader who started with the Lee portable “whack-it-with-a-hammer” handheld reloading outfit and progressed through single-stage and turret presses, I was keen to produce ammo in quantity on a true progressive press.

I had always wanted to try a Big Blue press, and now I’ve fulfilled that wish. This Dillon Precision press is a marvel of engineering and construction and should last years.

What do you think of the XL750? Let us know in the comments below. For more on reloading, head to our Ultimate Reloading Guide.

5 Leave a Reply

Reloading since 1976 with a number of machines including the 650 and 750. I'll keep my 650 and sell the 750, what a POS. Primer slides always sticks and even had one primer go off which since I started reloading has NEVER happened. Case tray sends down upside down cases (300 ACC), std powder charger does not create and kind of case bell so that the 220+ gr bullets will sit properly and have to be feed up into the seating die. Had to recalibrate the "NEVER NEEDS" calibration station plate. I have 100's of bad 9mm/40 loads that are going to have to be pulled as primer are upside down, sideways and crushed, etc. The 300 ACC seems the worst. The 650 pushes new primers, get a primer catch, it works.

Sorry Mike, but you're wrong, the extraction spring is just that, an extraction spring, there's a set screw in the side of the ram that locks the shell plate bolt from tightening up, you might want to look at your manual again, uses 1/8" allen wrench

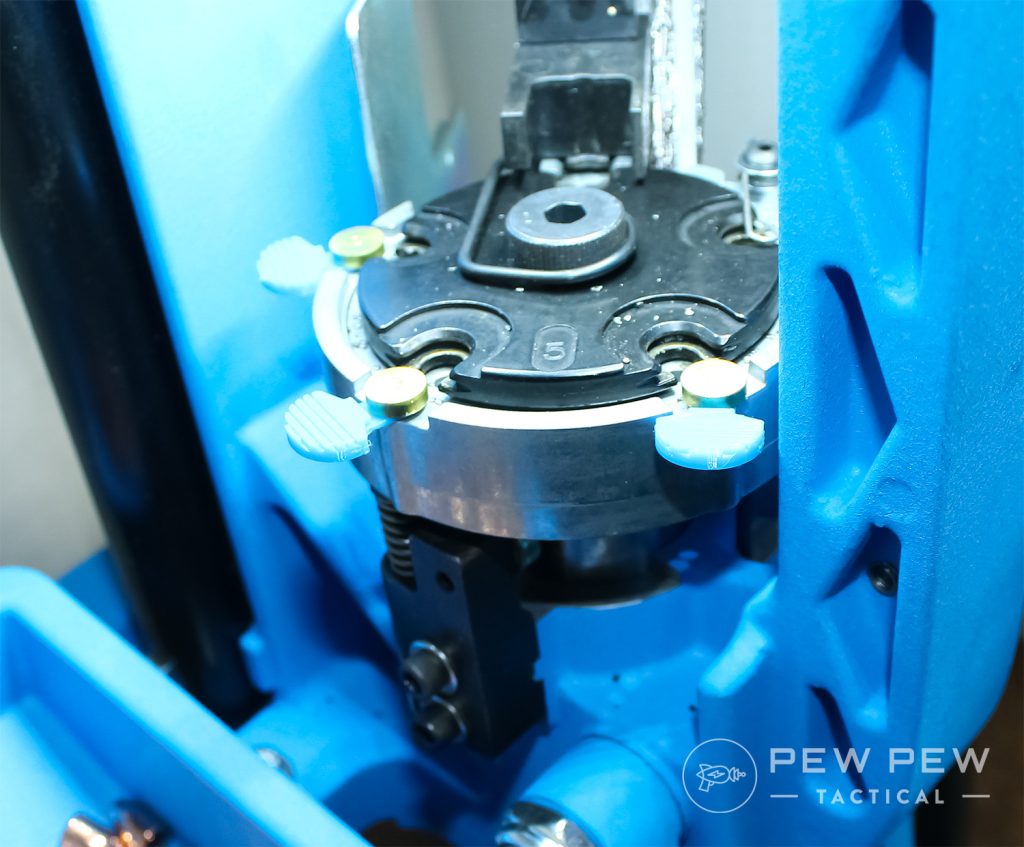

In the image above, the marking isn't for station 5, it is shell plate 5(9mm, 9x21, 38 Super). There are also 5 operations per pull of the handle(5 stations) not 4. That allows you to use a bullet feeder or powder check and you can crimp as a separate operation.

Good Article Mike. I've friends with Dillon, but the Progressive Press Bug has never bit me yet. I'm still using the same Single Stage Press I've used for over 40 years, and at this point of my life, why change. Also, I can't justify the expense at this point.

TBTH, I enjoy the Reloading Process almost as much as I do shooting the Ammo. The attention to every detail satisfies my OCD (LOL), and I've never viewed it as a chore.

Reloading still can save a guy money, though not as much as it used to. Back when I started in the late 70s, within a year or two, the money I saved pretty much paid off the equipment expenditure. It takes a bit longer today than it did back then.

Component Prices and availability are big issues today, especially Primers and Powder avaiability. Primers are still at least twice what they cost PrePandemic, and the ridiculous prices during the Pandemic caused me to back off Reloading during that time. Had I known how ridiculous they would be, I would've stockpiled far more than I did.

Thoroughly enjoyed your review, and look forward to your next article my friend.

Dillon are fantastic. I bought a **650 from them in the mid 1990's. I eventually gave it to my son.. I had no problems with it so I never called. I topped hern from Dillon when they ended the monthly magazine. I bought an XL 750 about 18 months ago. When I called I gave them my name and a few key clacks and BAM , ah yes we haven't herd from you in a while, still the same shipping address? (it wasn't. I'm not as stable as Dillon, lol)