Want to build your own Glock to your own specifications?

Polymer80’s frame kits ($149) let you do just that…in the comfort of your own home. And unlike other 80% projects where you have to mill aluminum…this time you don’t even need a drill press.

We’ve built a couple the past year and all with tons of different triggers, frames, and sights.

By the end, you’ll know exactly what to buy to meet your end purpose and budget. Plus everything we’ve learned along the way to make your build as painless as possible.

Table of Contents

Loading…

Should You Even Do This?

Disclaimer: This is purely educational (and we’re not lawyers)…you’re building a firearm so make sure you’re legal and safe. If you run into trouble while building, please consult a qualified gunsmith.

Legal

There has to be some cutoff of where a piece of metal or polymer becomes a gun. The 80% is industry slang but it’s where the ATF deems something not a firearm.

Polymer80’s Glock PF940Cv1 (compact like the Glock 19) and PF940v2 (standard size like the Glock 17) allow mostly everyone to build an unregistered firearm at home provided you they legally own one already.

But be sure to check your individual state/local laws.

“Individuals manufacturing sporting-type firearms for their own use need not hold Federal Firearms Licenses (FFLs). However, we suggest that the manufacturer at least identify the firearm with a serial number as a safeguard in the event that the firearm is lost or stolen. Also, the firearm should be identified as required in 27 CFR478.92 if it is sold or otherwise lawfully transferred in the future.” -BATFE

Difficulty

I’d estimate 25% difficulty compared to completing an AR-15 80% build. It’s really not that hard if you’re semi-capable with hand tools and don’t rush things.

You’re dealing with polymer instead of aluminum in a standard 80% AR-15 lower build.

Tools Needed

There’s lots of ways to do this since you’re only dealing with polymer.

Bare Minimum

It might take a little longer…but this will get you through it. Plus useful for other gun and home projects.

- Hand drill (for the pin holes)…or a Dremel ($39) that can hold drill bits

- Needle Files ($8)

- Assorted Sandpaper ($8)

- Nylon Hammer ($15)

- Glock Front Sight Tool ($6)…or a 3/16″ nut driver

- Nylon Sight Drift Tool ($8)

Recommended

- Drill Press (if you already have one…this makes milling pretty easy)

- Brass Punches ($17) (easier to put in pins, brass for not marring your metal surfaces)

- Thread Locker (Medium) ($5) for the front sight screw

Easiest

- Universal Sight Pusher ($140)

- End Snips ($13): No more milling…simply snip off the rail polymer segment and finish off by hand-filing

Now that you’ve got all the tools…what else do you need?

Parts List

Polymer80% Kit

First…choose the size. If you want to build a full-size Glock 17/22/33/34/35, get the PF940v2.

There’s also an aggressive texture one only from Brownells. I personally like the regular “frame textured” which is already light years better than a stock Glock.

“Ready-mod” means that the grip is smooth so you can do what you want…from stippling to adding your favorite grip tape.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

If you’re looking for a compact Glock like the 19/23/32, get the PF940CV1.

And now more recently…if you want the single stack G43 series…get the PF9SS.

Frame Completion Kit

All my builds have been with this so it works for me. The trigger is actually quite good and better than the stock Glock one. I also like how it comes with the 3.5 lb connector, and extended versions of the slide lock lever, slide stop, and magazine catch.

Make sure you get the correct full-size or compact version. The PF9SS (G43) will also have different parts.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

In desperate times you might have to search for any available Glock Completion Kits.

Glock Slide

Make sure you get a Gen 3 Glock slide so that it fits perfectly with the P80 frame. Gen 4 ones have a gap which will likely lead to some problems down the road.

You can opt for complete versions with everything installed including the barrel, or piece everything together yourself.

Check out our Best Aftermarket Glock Slides article for all our recommendations.

But the go-to affordable option is Brownell’s where you can get windowed and RMR (red dot) cut slides.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Slide Completion Kit

Depending on if you get a complete slide or a bare one…you might need a slide completion kit. I have used Lone Wolf’s and it’s good to go.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Glock Barrel

If you went with a slide without a barrel, check out our Best Glock Barrels article.

I really like Faxon’s Glock Barrels because of their increased accuracy and looks (full review).

What’s the point of customizing if you can’t make it your own.

And for the budget build…I’d go with Brownell’s editions made by Victory First which seems to have great reviews.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Glock Sights

If it’s a more practical gun…I’d stick with Glock OEM night sights.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

You can check out more of our favorite iron sights at Best Glock Sights.

And if you’re going the red dot route…check out Best Pistol Red Dots.

Our top pick is the Trijicon RMR Mod 2 since most frames are milled for it.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Upgraded Glock Triggers

Although the stock Lone Wolf trigger is pretty decent…it can always get better.

We cover a few of the most Best Glock Aftermarket Triggers (and the infamous 25 cent trigger job) and our favorite is actually the most budget friendly with Apex.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Pistol Lights

You can’t shoot what you can’t see and identify. We tested out the most popular ones.

Our favorite and best-bang-for-the-buck is the Streamlight TLR-1

Check out the rest (and each light’s beam spread) in Best Pistol Lights.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

That should cover everything…now let’s get building!

How to Build: Milling & Drilling

Make sure to follow the instructions straight from Polymer80. This is just how I did it for a couple frames.

This should be what you get in your kit with some variations in size of the frame and color.

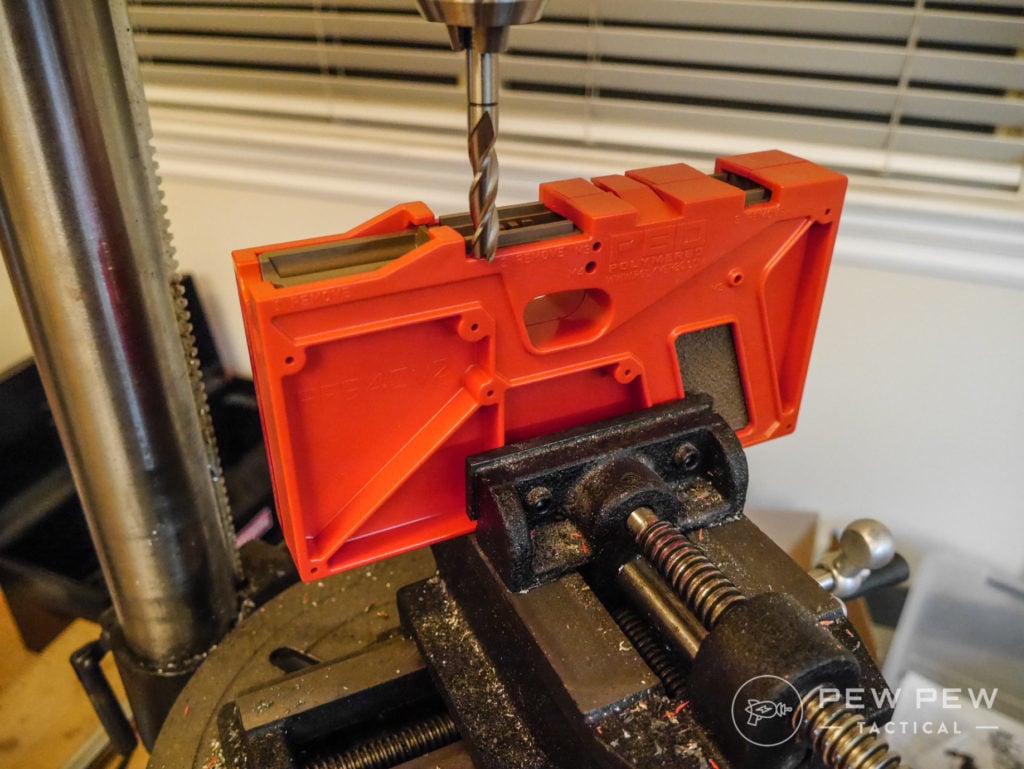

If you’re going the milling route…load it up on your vise but not too hard. Otherwise, get crackin’ on hand-filing everything!

Put in the milling bit a little above the red…you’re going to hand finish it.

I start by moving in the larger front segment.

And finish up the segment slowly.

Then do the same for the rear small segment.

You can see the final results from only the mill bit.

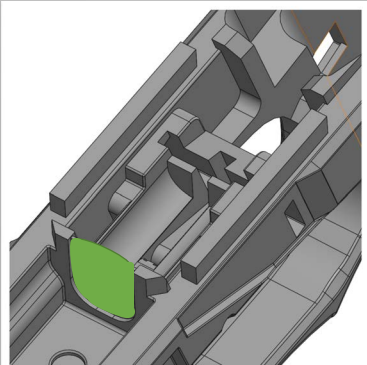

Next up is the hardest bit…milling out the Barrel Block.

Official instructions is to flip the jig and continue to use the mill bit. But my first one caused a lot of vibrations and started going off track.

I would suggest doing it entirely by hand…or starting it off with a Dremel and a grinding attachment.

Go slowly and don’t try to remove everything in one go.

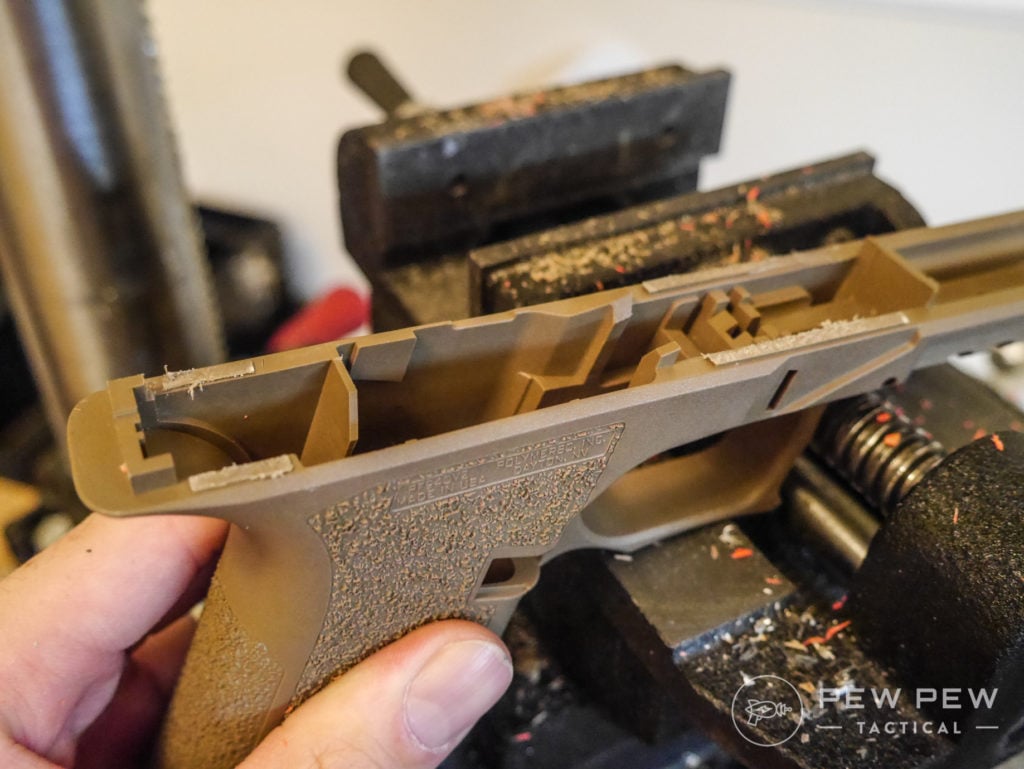

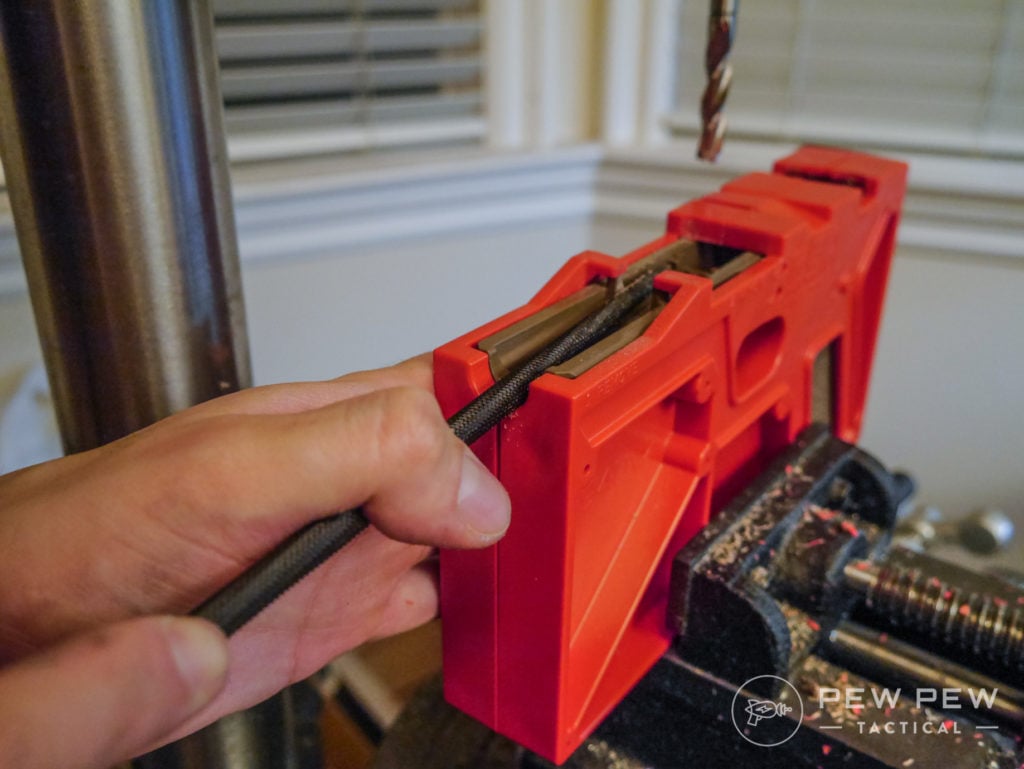

Now come the hand tools to finish everything off. If you have more robust files like I do lying around…it’s going to go a lot faster. But the small ones I recommend will also work…you just need a little more patience.

Here I’m filing the frame so there’s close to no more residual.

Almost there with the hand tools.

I stop when it’s rough but flush.

And for the rear segment.

Now I grab the sandpaper…I start off a little rougher and graduate to something pretty high grit (less rough). You can also wrap it around something hard and straight if you don’t trust yourself.

And for the barrel block I roll up a piece of sandpaper. You can also wrap it around something cylindrical for more force. Pay extra attention here since the smoother it is the smoother your slide action will be since it’s where the recoil spring lives.

The end result for the frame.

And for the barrel block.

It still wasn’t super smooth when I assembled everything so I went back and evened it out some more…and made sure there wasn’t stuff to snag on the sides.

Here’s the end result of my two P80s.

And from the front. It’s pretty forgiving as you can see my first gray one had an oopsie with the mill bit on the top right.

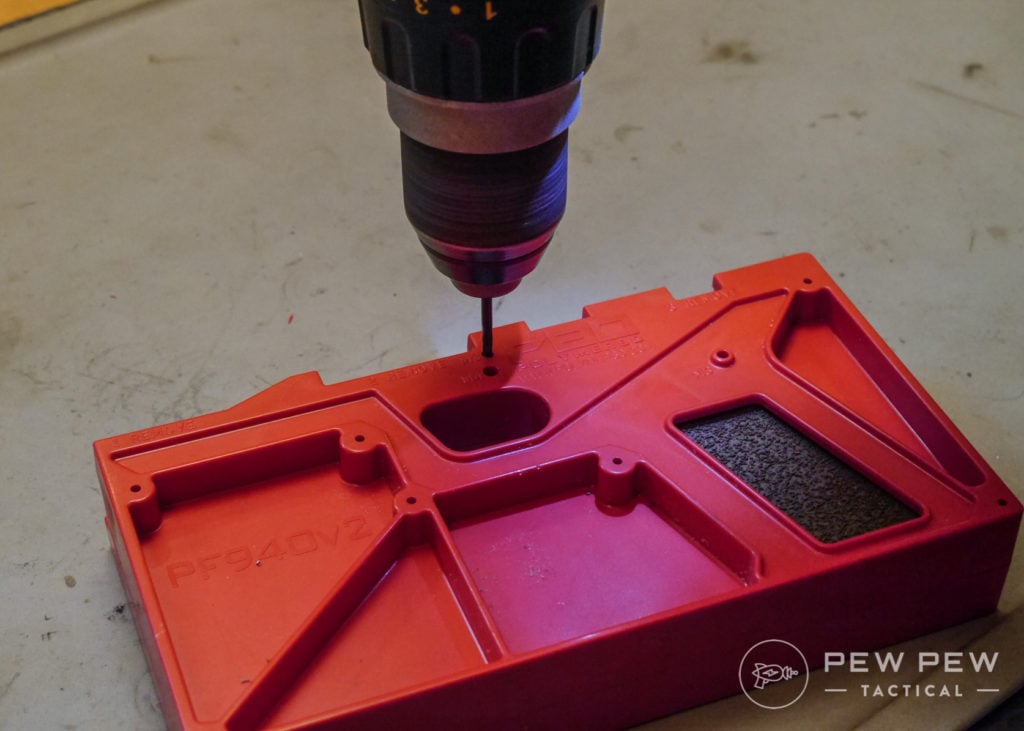

That wasn’t so bad…was it? Now you just have six easy hand drill portions left.

Make sure to use the correct bit, not have it in a vise, use a hand drill, and go side by side (not all the way through). 3 drills on each side for a total of 6.

But wait…what about the end snips?

Turns out…they are perfect for cutting off the frame parts! I’ll be trying this in a future build.

How to Assemble: Polymer 80 Frame

Now…let’s assemble everything! Some pictures will have my upgraded trigger (gold colored) since I went back and retook some pictures that weren’t clear.

First let’s start with the magazine release. It’s pretty difficult to show through pictures so here’s one of my old videos:

Next let’s put in the slide lock spring…this is different for the full-size and compact sizes so be sure! It may be a little hard to push it in all the way into the hole in the frame.

Then get your slide lock…it’s not symmetrical so make sure you can see the side with the “teeth” and have it face the rear. Don’t mess this up since it catches the barrel lug (aka keeps your barrel/slide from flying off).

Press down on the spring with something and slide the lock in.

Correct orientation of slide lock.

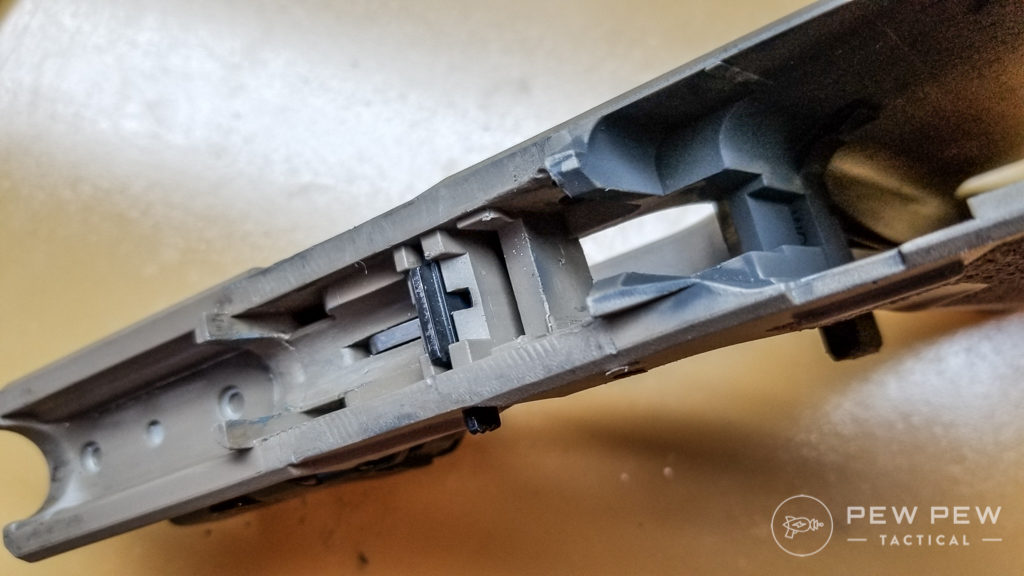

Next it’s time to add Polymer80 specific metal parts to beef up your polymer frame.

First…the locking block rail system (LRBS).

For the first time it’s usually really hard to put in. Be patient and you can use light taps from your non-metal hammer.

Then tap the pin through with a punch (left-most hole). I like to look through the hole to see if it’s completely clear to save unnecessary banging.

Next is the rear rail module (RRM). Push it in but no pin yet since we’ll need to add the trigger first.

Gather up your trigger parts and assemble.

This gets a little confusing so here’s another video of mine:

Place the completed trigger into the frame.

Get the polymer trigger pin and punch that in.

Then the smaller metal pin.

Take the slide stop lever and insert it so that the spring is underneath the just put in smaller pin.

Punch in the bigger pin.

This was difficult the first few times since you have to wiggle the slide stop lever…and everything is really tight. I recommend using a punch as a slave pin so everything is already oriented.

And…done!

How to Assemble: Glock Slide

If your slide came pre-assembled…you’re in luck. Otherwise it’s not too bad!

First start assembling the firing pin and extractor plunger.

Push down on the spring and then add the spring cups on top of the spring(takes a little practice…make sure you’re wearing eye protection throughout and maybe point everything in a cardboard box to catch lost parts).

Smush the extractor plunger parts together and there you have it.

Now grab your firing pin safety, spring, and extractor. Place the firing pin safety and spring into its hole.

Orient the extractor and press down on the firing pin safety while fitting in the extractor.

Once you release the firing pin safety…the extractor should stay.

Next is placing the completed firing pin and extractor plunger assemblies.

Grab the slide cover plate and use a punch to press down on the firing pin and extractor plunger assemblies until everything clicks into place.

Now place in the barrel and the recoil spring (with the dome shape towards the front of the slide).

If you’re looking at adding sights…bare minimum get Nylon Punch Tool. The front sight is added with a 3/16″ nut driver. I’d recommend adding some thread locker to the screws too.

And you’re done!

Now you have your own self-made Glock!

Safety Checks

With no ammo in the gun or in the room…run through some safety checks. Even better…get it checked out by a qualified gunsmith before shooting for real.

- Oil the rails up and make sure the slide returns to battery even when only a little racked

- Make sure the trigger safety works

- Depress and hold the trigger, and rack the slide…make sure the trigger resets and can be pressed again

- Use a wooden pencil and put it down the barrel…see if it shoots out when you press the trigger

Polymer80 Troubleshooting

Not working? Here’s some common problems and fixes.

Use Original Parts

Whatever part is not working…try it all with stock OEM parts. Sometimes aftermarket slides and triggers have too tight tolerances to work in a P80. So far the Brownells and Grey Ghost (a little tight) have worked in my builds. I’ve heard ZEV slides might be too tight.

Trigger Not Resetting

If it’s especially bad on one side orientation, you might want to grind off off a little bit of the polymer in the rear right side rail.

It should get better each time you grind a little off. If it’s still not completely fixed at all orientations…check to see if the rear rails are of different height.

If it is…it will cause the slide to tilt and get stuck somewhere.

You’ll have to file the higher metal rail down a little if that’s the case.

Slide Getting Stuck

A little grittiness is ok since it’s a new build and things will get smoothed out with use. But if you’re having difficulty getting the slide on…check the slide lock spring so it’s not poking up and snagging on the recoil spring.

Misaligned Holes

If you just can’t get the pins to go through (especially on the rear polymer one)…and you look through to see obstructions. You can re-drill carefully.

Rough Feeling

If the slide feels rough…again it’s the barrel block area. Make sure it’s smooth and you can run something along the bottom and make sure nothing snags.

Review

Not much to say here…it’s a great 80% project that’s easier than doing an AR-15. You also won’t end up saving money compared to buying a stock Glock at your local FFL.

But when you’re done, you’ll be left with a sense of pride and accomplishment. And of course…a fully customized Glock that’s off the books.

I like the grip angle a lot more (I believe it’s closer to a 1911) and also the lack of finger grooves. Those things are made for the “average” hand that no one really has.

Plus…the regular frame textured one is a great balance of the stock pattern and stippling yourself. Because of these factors…I get a much better, higher, and more positive grip.

As long as you go slowly (you can’t ADD on polymer) you should end up with a pretty reliable Glock clone. The main problems will come when you try to add too many upgraded parts at once. Remember…process of elimination if you end up with problems.

I’m about 1000 rounds through my grey one and 500 rounds through my brown one. Besides some initial break-in hiccups on the first few mag changes…and it hating my low-power reloads…it’s run flawlessly with factory ammo.

I fully recommend doing a Polymer80 Glock project.

Prices accurate at time of writing

Prices accurate at time of writing

-

25% off all OAKLEY products - OAKLEY25

Copied! Visit Merchant

Conclusion & Additional Resources

Here’s some links to all our Glock stuff again so you can choose what’s the best for you.

- Best Aftermarket Glock Slides

- Best Glock Barrels

- Best Glock Sights

- Best Pistol Red Dots

- Best Glock Aftermarket Triggers

- Best Pistol Lights

How did we do? Anything we’re missing? And how did your build turn out? Get through all that and decide building a Glock isn’t for you? See our choices for the best Glocks of all time.

62 Leave a Reply

Great job, well explained !

Great man , thank you so much.

You don't mention the installation of the channel liner.

Thank you for making these how tos. I always come back to you each time I assemble anything. Ar’s and now going to try one of these I think. Thank you very much

When you clip the tabs use a "fret cutter" available on Amazon, this will cut them perfectly flush. Also having an issue with the trigger not resetting on a 43 and 26, the tip on the trigger bar hitting the frame may do the trick. The 21 has plenty of clearance between the trigger bar and frame and resets perfect every time.

My P80 keeps won’t eject rounds

Ditto

Get a 30274 ejector

IMPORTANT! I eventually figured out why my gat wasn't resetting, it was because I didn't install the channel liner. PEWPEW MISSED A CRITICAL STEP! The gun will not cycle properly without the channel liner.

So I guess this slide is one of the channel liner exempt models.

You didn't follow instructions. You drill the holes first, since the tabs help keep the frame aligned in the jig. Also you didn't install a channel liner.

The biggest problem is fitting the front and rear rail blocks. They do not fit correctly, they are the parts you have to spend the most time and effort modifying. Google 'Marine Builder'.

Wait... did I miss you installing the firing pin channel liner? You MUST install this on a bare slide unless the slide maker has previous installed it for you. If you are using a used slide it would be already installed. I was looking at a custom slide and the installation of the channel liner was an option.

Hi. What are the best magazines for a P80 compact in 9mm? Thanks

Hi.

Are Magpul magazines compatible with the P80 9mm compact?

Thanks,

Mark

Do you still recommend gen 3 slides, or is a gen 5 the right choice now?

Gen 3 and gen 5 are not compatible, to my knowledge all of the P80 sets are built using the gen 3 design and MUST use gen 3 slides.

I could be wrong but did you leave recoil spring off the parts list?

Polymer80 has very poor customer service I emailed them about missing parts in the trigger kit that came with the lower. I bought the kit from mid-way USA and was directed to contact polymer80 to report the problem. It’s been over a month and sent two emails about the issue. Be aware the before buying that they will not respond to emails and your issues. I even sent images because I received extra parts in the tigger kit. I was missing two parts in the tigger kit.

My trigger kit came with two

Small Allen bolts & tiny Allen wrench don’t know where the go also having ejection issues basically no ejection any help plz

Anywhere I can buy a rear rail ?

Buy beware: Polymer80 promises a hassle-free warranty. After more than 26 photos, over 50 emails and continued requests for warranty replacement for over 6 weeks. Polymer80 has attempted to restart the warranty request process 3 times. I've had to dissembled the frame twice to provide photos beyond their normal requested photos. Support claims that I didn't send photos they requested.. I've even had emails rejected from polymer80.

And Polymer80 is still photos beyond their normally requested photos for an obvious broken frame.

My Poly 80/ Glock 23 does not release the magazine. When depressed the magazine release unlocks the magazine, but it does not move it down the handle. 1. Is there a specific generation magazine that should be used on the Poly 80? 2. What could be done to correct this problem? Other than this glitch, the weapon functions perfectly.

Wrap blue painters tape around the mag, about 3-4 wraps will do. Insert it into the mag well and fully seat it. Get your wife’s hair dryer, on the hottest setting, and heat up the area of the grip to the point it’s too hot to hold onto. Leave the mag inserted and allow to cool completely. This process will ever so slightly enlarge the mag well and will allow mags to drop free more easily.

Heads up all - LWD parts are not longer covered under P80's frame warranty. Just blew mine because I reached out to try and get a new rear rail for my PF940CV1 (there has been some alignment issues from what I researched) and they refused to help me out because they saw that I had LWD LPKs installed...

Even if you go on the P80 website for the frame, they now exclusively state that use of LWD voids the warranty - hope this helps future P80s builders out there - Too bad because LWD looked g2g but I prefer to keep my warranty

@ “J”...My h da Nash hit a snag also but the jjdjsjdkd SJSU’s iDisks Habsburg didn’t void my warranty.

Did you check the hdjsievs dude jejsisj chuff ? It could also be the yts’s. Check page number 98875467397658637 in the hand book and you should be g2g.

What is that open top red dot sight in a couple of those photos??

It's not quite a red dot, but not an iron sight either - it's the SeeAll Open Sight!

Is the length of the grip the exact same as on the Glock 19 or is it a little longer? The 19 is a little short for my hand but i want a 4" barrel so i can add a Compensater, without feeling like I'm holding a Dirty Hairy revolver, on a G17. Or would possibly adding a Magwell flair help with this?

I have a compact P80 frame inbound from Brownell's. I also bought a Thompson Leh G3 Slide, DLC Black, Trijicon RMR Cutout and Cover Plate on Ebay for $199 delivered. That's $150 off their regular price.

Can I make a suggestion? I'm building my very first P80, After following your instructions to assembling it (which are awesome by the way) I noticed I had a left over part. That's never a good sign. After doing some digging I realized you left out the instructions to install the GLOCK FIRING PIN CHANNEL LINER. You have a picture of it included in your parts shot but no mention of it or how to install it. On you tube they suggested just a regular Bic pen to push it in, which worked flawlessly. Thank you for the article, other than that it's awesome!!

Question, should I purchased a stock Glock or build a poly80? What’s the better option? I do wanna upgrade the parts in a later time when I do buy a stock Glock but isn’t that just a waste of time and money? Help me please! Thank you.

Out of curiosity... What features would you modify if you were building this as competition G17? I'm asking since you said neither build liked your low power reloads... what would the fix be for that?

I assume that one is to purchase a guide rod and recoil spring. I see them in the pics but not discussed. I'm going to try this over the Thanksgiving holiday. Will be my first time.

I'm wondering this as well. The completed slides come with a recoil spring, but the slide completion kit doesn't, so that would still be missing if you bought that kit and a stripped slide.

If you buy the kit made by Glock from Brownells it comes with a recoil spring (but you can't apply coupons to Glock products). If you get a third party kit (Lone Wolf, P80, etc they most likely don't (but you can apply discount coupons). Use code "NCS" on orders over $150; it's about 10% off plus free basic shipping.

You can get a complete slide from Ghost Guns for about $460 if I remember. It's all stock Glock so you can customize what you want later.

The article needs to include this, otherwise it is incomplete.

Thanks for the article. This is easily the most cost effective way to get a custom glock type gun. Why buy a standard glock then replace half the parts or pay to mill a standard slide. If you watch for deals on parts this is not much more expensive than a standard glock, but it's designed specifically to what you want.

This is an awesome guide. I am definitely doing this project. Thanks for taking the time to post this.

Of course! We're glad you enjoyed it.

I'm liking the lower with the gold trigger. What color frame is that?

Hey there! That'd be the Flat Dark Earth frame

Eric, with all due respect, I believe the LWD kit is NOT a good idea for these, and would strongly recommend Glock parts. I've also built three of them.

My PF940C with the LWD kit had failures to reset when I held the trigger all the way back as hard as I could. This is because the trigger is given more room to move, and you can actually cause the trigger bar to flex. This flexing causes the connector to be pushed inwards towards the frame, so much so that the slide failed to reset the trigger. You can test this out yourself with the slide off the frame, and it's pretty obvious if you have a "real" Glock to compare it to (as it doesn't suffer from trigger bar flex). The LWD connector is ever so slightly out of spec, and replacing it with a Glock connector solved the reset problem. The core problem here is a design flaw with trigger travel, but the LWD kit exacerbates it.

Further, IMHO, the LWD extended magazine release is horrible on these frames, and a standard Glock mag release works far better due to how the magazine release area is cut inwards towards the frame.

for some reason the trigger on my g19 polymer would never reset. even after grinding the metal piece down. i used an apex trigger just like yours (in fact, its a grey p80 with a grey ghost stippled slide and red apex trigger... exactly like yours)

i decided to swap the trigger and bar out for a stock one and now its working perfectly.... wonder if its the trigger bar.

It could definitely be...or some part of your P80 specifically that was touching it. Glad it's working though with stock parts!

I'm confused. I bought a 22lr revolver a couple weeks ago, I wanted to lengthen the barrel by about 2 inches so I asked where I could buy a replacement barrel on the manufactures website, they said that the gun was registered to me by the atf with a certain barrel length and if I change that I would need a new serial number. But in 1986 it was made illegal for any government agency including the atf (or even an ffl) to make a registry of gun owners or guns, so?

Do you think they will ever do this with other polymer pistols? I am not a big fan of DAO triggers/striker fired. But i do like this idea.

Most likely...there's a G26 one from P80, a G43 from SS80 and also a P320 kit. I haven't tried out those yet though.

End snips...Hah! I've done a few of these and never would have thought of that. Now I want to go do another one just to try out the snips. Thanks for the great idea.

Glad I could help!

You forgot the firing pin guide. It can be extremely difficult to install on an after market slide!

Good call...next time I clean up my Glock I'll get a quick video of putting it together.

I completed my Glock 17 last week, and I'll tell ya it was so much fun! The only customized part i installed was an extended slide stop because i always had trouble getting a solid grip on the stock option. Also i shot 200 defensive rounds with it just yesterday. It ran REALLY smooth. I might put in a custom trigger later on. My only regret is not getting a different color frame other than black. Oh well. If you're thinking about building one, just be patient with it. All the filing and sanding was the real work of this project. I wanted it perfect, because i saw what problems other people were having and it was because they rushed through it. So patience is the key.

Nice, Joe! Yup...more rounds in it will make it smoother and patience definitely is key.

Why not just buy a brand new G17 for a few hundred less ?

Sure can...this project is not for everyone.

Because it's a Ghost Gun from birth. If you don't see the value in that, then we have nothing further to talk about.

I like building models too. Ghost gun makes it sound special to many who don't need such a thing. Everyone wants to be a rebel ssshhhhhhhhhh... I have a gun nobody knows its a secret

I'm all for building your own guns at home, I've done 6 AR15s so far, 4 in 5.56 and 2 in 300BLK (one is a 10.5" pistol) and an AR10 in .308Win/7.62X51. Both polymer and aluminum, on a drill press with a compound table and vise. The most expensive was the AR10 at about $800.

But with the cost right now for a polymer Glock I can do better finding a used one for sale from a private party.

The cost of the frame is not that much more than an AR15 Lower. it's the rest of the parts.

Direct from Polymer80 all 3 frames with jig are $160.

Slide is $325 to $400, barrel is $175 to $225, Slide parts $100, and I don't see the frame parts listed.

$760 already with the cheapest parts and not even complete.

Used Glock as low as $400 or so on Armslist. But I don't want one, I have two Taurus 9mm. Pistols.

PT24/7 Pro LS DS and a PT111 Millennium G2.

Yup, you won't save money with building one your own (maybe break even with all the most budget parts). It's more about doing it by yourself and being able to choose all your parts.

Not true anymore!! Youc an still build one for around $500 ( more or less) if you are diligent about shopping around and waiting for deals. Try to buy a fugly Glock for $500 now!! LOL!!! This is the only glock I would ever own.

Boy have the times have changed. I built mine for $600 and it has some decent parts in it. It's crazy what a couple of years can do to weapon value and availability.